Silica negative electrode material and preparation method thereof

A negative electrode material, silicon-oxygen technology, applied in the field of silicon-oxygen negative electrode materials and its preparation, can solve the problems of volume expansion, reversible capacity reduction, battery cycle performance deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

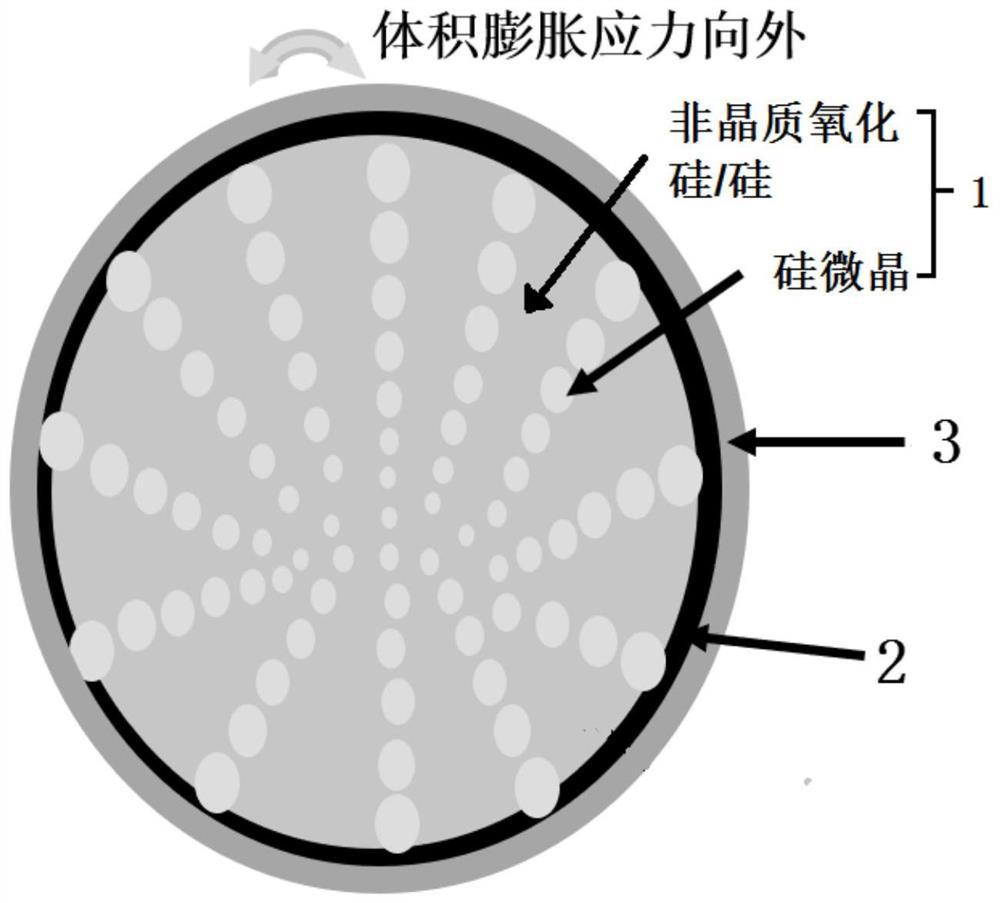

[0083] The second aspect of the embodiment of the present application provides a method for preparing a silicon-oxygen negative electrode material, including:

[0084] Using silicon oxide and carbon sources as raw materials, a core-shell structure with a core, a middle layer and an outer shell layer is prepared under dynamic heat preservation conditions.

[0085] Wherein, the intermediate layer is coated on the surface of the inner core, and the outer shell is coated on the surface of the intermediate layer,

[0086] The material of the inner core includes amorphous silicon oxide silicon oxide and silicon microcrystal, and along the direction from the center of the inner core to the surface of the inner core, the size of the silicon microcrystal increases gradually; the material of the middle layer is silicon carbide.

[0087] The preparation method of the silicon-oxygen negative electrode material provided in the embodiment of the present application uses silicon oxide and ca...

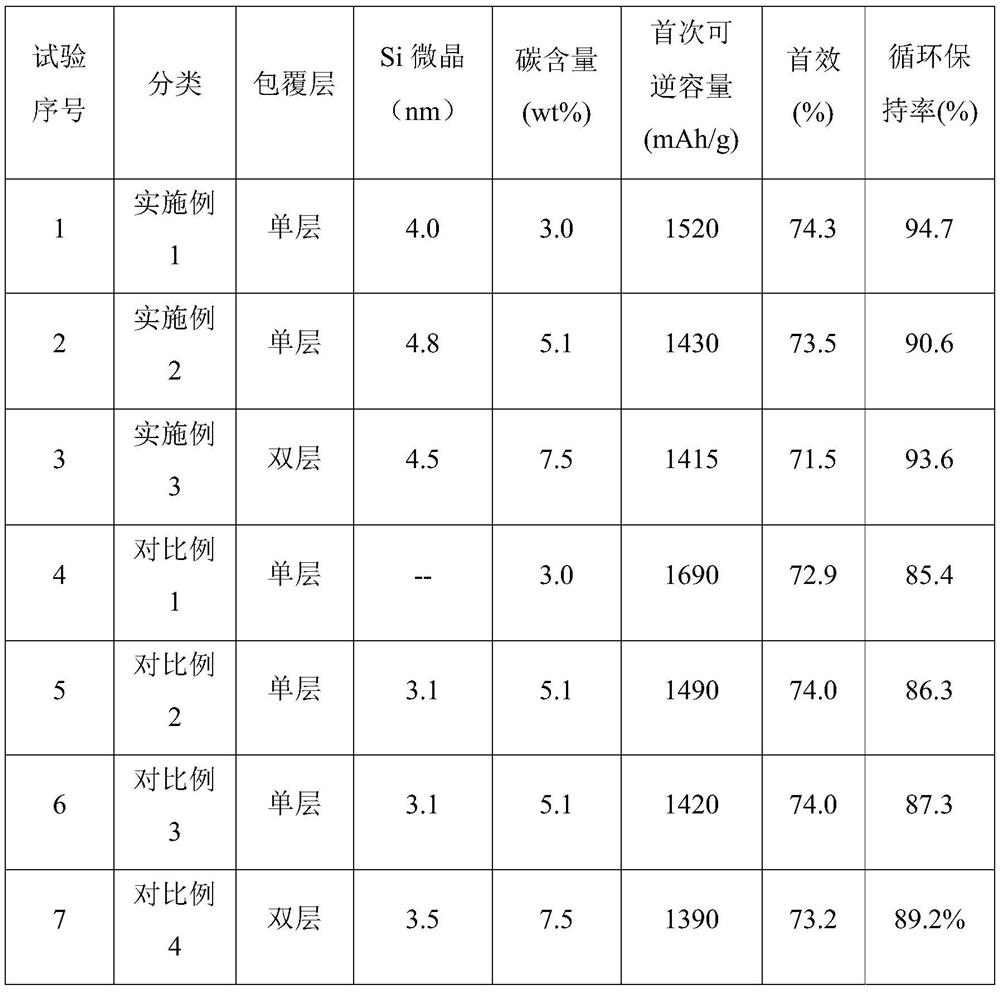

Embodiment 1

[0120] A method for preparing a silicon-oxygen negative electrode material, comprising:

[0121] 1kg SiO x The negative electrode material is placed in the rotary furnace, and the gas in the rotary furnace is replaced by Ar to ensure complete evacuation; after turning on the heating and raising the temperature to 750 °C at 5 °C / min, switch to acetylene / Ar mixed gas, and then dynamically keep the temperature for 1.5 hours. The surface layer of the material is uniformly covered with a carbon layer; switch the gas to Ar, further raise the temperature to 1200°C at 5°C / min and keep it for 20 minutes, and take out the material after falling to room temperature under the protection of a non-oxidizing gas to obtain conductive silicon with a silicon microcrystalline gradient distribution structure Oxygen complexes were analyzed by a carbon-sulfur analyzer to obtain a carbon coating amount of 3.0 wt%.

Embodiment 2

[0123] A method for preparing a silicon-oxygen negative electrode material, comprising:

[0124] 1kg SiO x After mixing evenly with 80g of petroleum-based asphalt through a high-temperature coating machine, place it in a rotary furnace and replace it with Ar to ensure complete evacuation. Turn on the heating and raise the temperature to 1150°C at 5°C / min and then keep it dynamic for 2 hours. The surface of the material is completely carbonized The material was taken out after being lowered to room temperature under the protection of a non-oxidizing gas, and a conductive silicon-oxygen composite with a silicon crystallite gradient distribution structure was obtained, and a carbon coating amount of 5.1wt% was obtained by analyzing with a carbon-sulfur analyzer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com