Porous carbon self-reduction preparation method of porous carbon loaded small-size precious metal nanoparticle composite material

A technology of metal nanoparticles and composite materials, which is applied in the field of nanomaterial preparation and electrocatalysis, can solve the problems of unreduced cost, complicated preparation steps, cumbersome preparation process, etc., and achieve excellent catalytic activity, high-efficiency catalytic activity, and simple synthesis method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

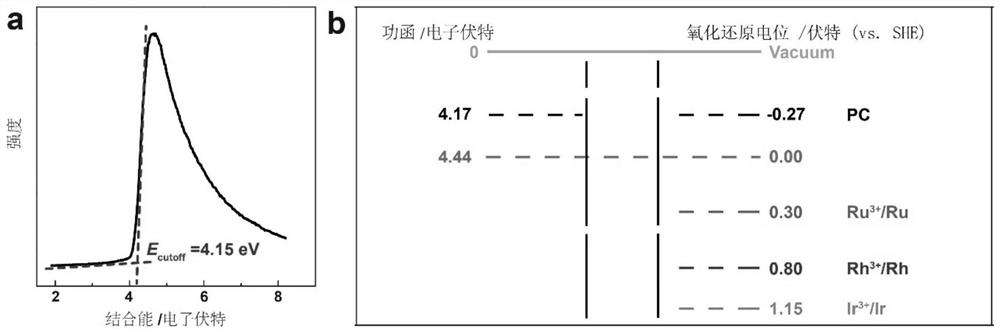

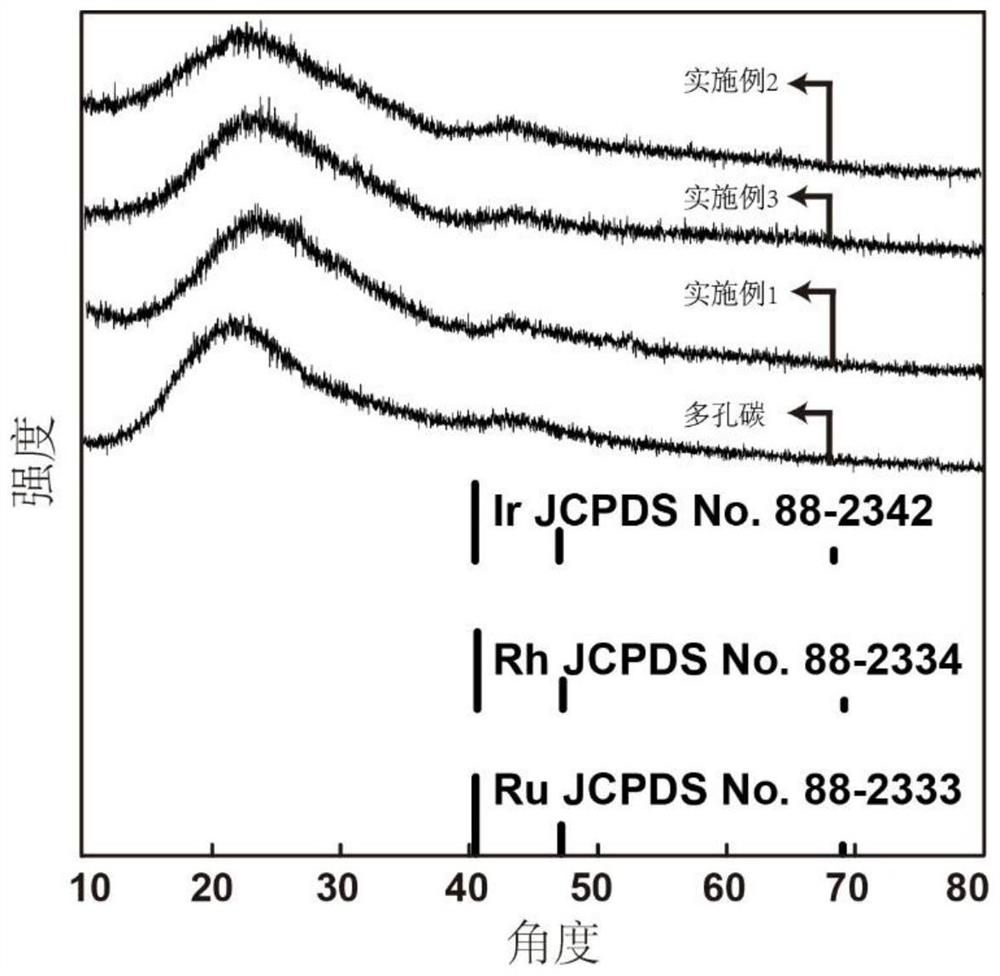

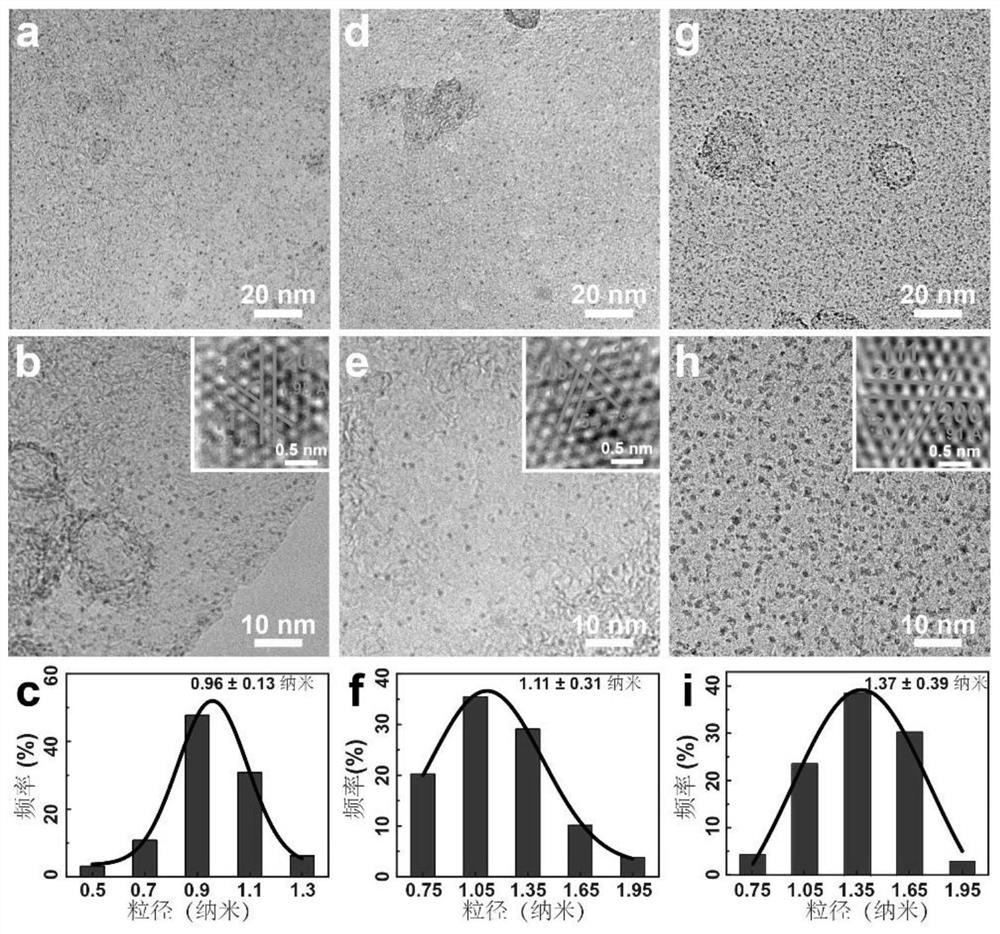

[0058] Examples 1-9: Preparation of porous carbon-supported small-sized noble metal nanoparticle composites

Embodiment 1

[0059] Example 1 Preparation of porous carbon-supported small-sized ruthenium nanoparticle composites

[0060] The small-sized ruthenium nanoparticle composite material supported by porous carbon is prepared according to the following steps:

[0061] (1) Using potassium citrate as a carbon source, calcining at 800° C. for 1 hour, acid soaking, washing, and drying to obtain the porous carbon material; the average pore diameter is 2.33 nanometers, and the specific surface area is 2208 square meters per gram.

[0062] (2) Add 40 mg of the above-mentioned porous carbon as a carrier to 25 ml of water, and ultrasonically disperse evenly;

[0063] (3) 0.2 millimoles of ruthenium trichloride hydrate was dissolved in 25 milliliters of water, and ultrasonically dispersed evenly;

[0064] (4) Add the porous carbon dispersion prepared in (1) to the ruthenium metal salt solution prepared in (2), stir at room temperature (25° C.) for 12 hours to complete the self-reduction reaction of th...

Embodiment 2

[0065] Example 2 Preparation of porous carbon-supported small-sized iridium nanoparticles composites

[0066] The porous carbon-supported small-sized iridium nanoparticle composite material was prepared according to the same method as in Example 1, except that the noble metal salt was replaced with iridium trichloride hydrate to obtain a porous carbon-supported small-sized iridium metal nanoparticle composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com