Branched hydrophobic end-modified associative water-based urethane thickener as well as preparation method and application thereof

An end-modified and associative technology, used in polyurea/polyurethane coatings, coatings, etc., and can solve problems such as poor water solubility, excessive molecular weight, and poor dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

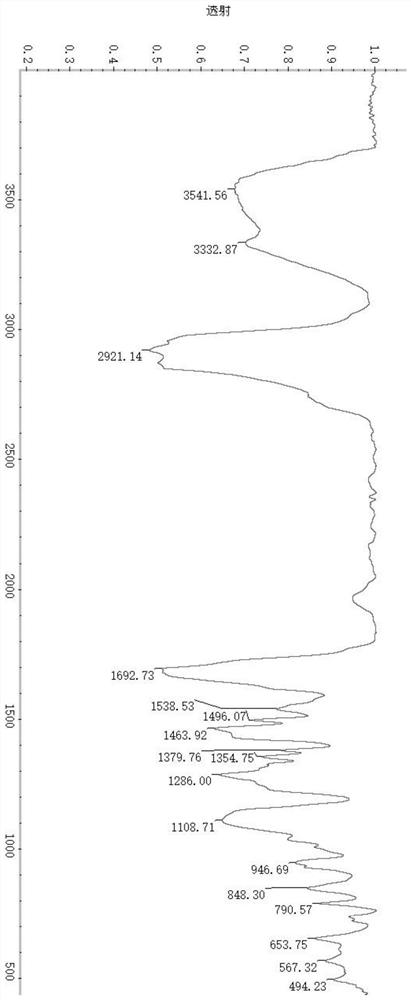

Image

Examples

Embodiment 1

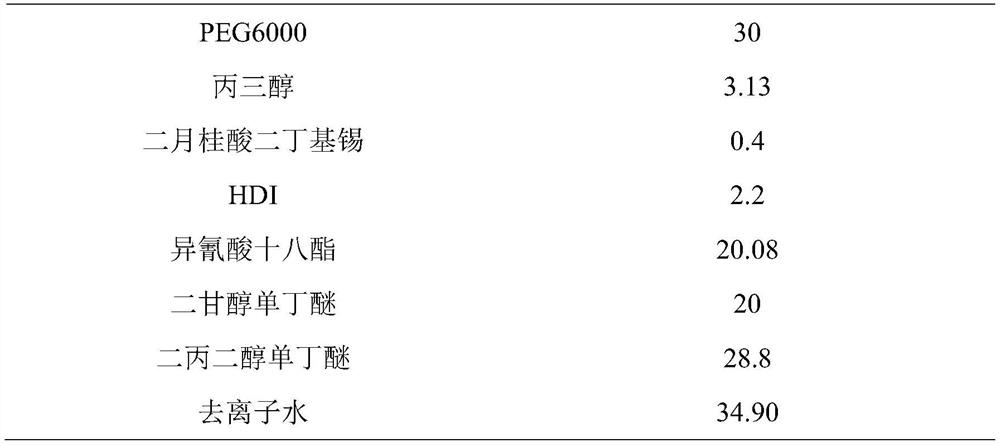

[0035] Raw material formula:

[0036] Table 1

[0037]

[0038] The preparation method of branched hydrophobic terminal modified associative water-based urethane thickener comprises the following steps:

[0039] 1) Preparation of branched end-capping agent: first add 2.2 g of glycerol to the reaction vessel, heat up to 100°C-140°C, vacuum dehydrate for 3 hours, dehydrate until the water content is lower than 300ppm, and then cool the system under the protection of nitrogen to Slowly add 20.08g of octadecyl isocyanate dropwise to the reaction vessel at 60°C. After the dropwise addition, add 0.2g of dibutyltin dilaurate dropwise and react at 70°C for 3 hours to obtain a branched modified sealant containing a single hydroxyl group. terminal agent;

[0040] 2) Preparation of branched hydrophobic end-modified associative water-based urethane thickener: add 30g PEG6000 to the reaction vessel, heat up to 100°C, dehydrate in vacuum for 3 hours, dehydrate until the water content i...

Embodiment 2

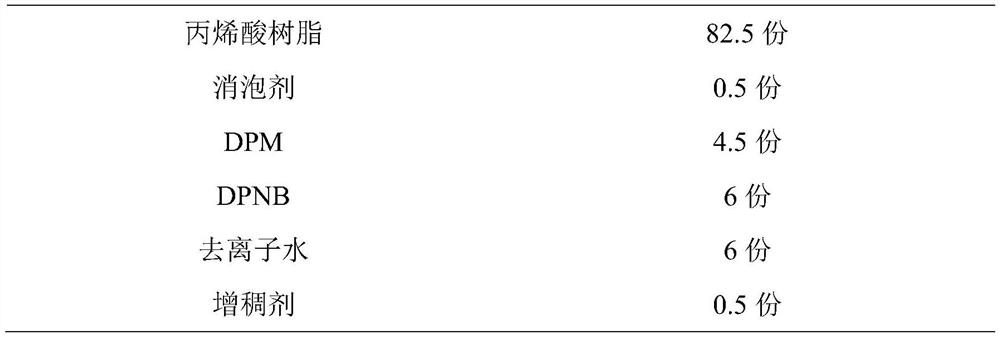

[0055] Raw material formula:

[0056] Table 4

[0057]

[0058]

[0059] The preparation method of branched hydrophobic terminal modified associative water-based urethane thickener comprises the following steps:

[0060] 1) Preparation of branched end-capping agent: first add 2.72g of pentaerythritol to the reaction vessel, heat up to 140°C, vacuum dehydrate for 5h, dehydrate until the water content is lower than 300ppm, then cool the system to 70°C under the protection of nitrogen, slowly add to 11.91g of butyl isocyanate was added dropwise into the reaction vessel, and after the addition was completed, 0.1g of organic bismuth was added dropwise, and reacted at 100°C for 2 hours to obtain a branched modified end-capping agent containing a single hydroxyl group;

[0061] 2) Preparation of branched hydrophobic end-modified associative water-based urethane thickener: add 10g PEG1000 to the reaction vessel, heat up to 140°C, vacuum dehydrate for 5h, dehydrate until the wat...

Embodiment 3

[0067] Raw material formula:

[0068] Table 6

[0069]

[0070]

[0071] The preparation method of branched hydrophobic terminal modified associative water-based urethane thickener comprises the following steps:

[0072] 1) Preparation of branched end-capping agent: first add 5.08g of dipentaerythritol into the reaction vessel, raise the temperature to 120°C, vacuum dehydrate for 4h, dehydrate until the water content is lower than 300ppm, then cool the system to 65°C under the protection of nitrogen, slowly Add 16.10 g of hexadecyl isocyanate dropwise to the reaction vessel. After the dropwise addition, add 1 g of stannous octoate dropwise and react at 80° C. for 5 hours to obtain a branched modified end-capping agent containing a single hydroxyl group;

[0073]2) Preparation of branched hydrophobic end-modified associative water-based urethane thickener: Add 80g PEG8000 into the reaction vessel, heat up to 130°C, vacuum dehydrate for 4 hours, dehydrate until the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com