A kind of concrete release agent and preparation method thereof

A technology of concrete release agent and antirust agent, which is applied in the direction of manufacturing tools, lubricating compositions, ceramic molding machines, etc., can solve the problems of corrosion resistance and insufficient heat conduction speed, and achieve excellent heat conduction and thermal cracking resistance, excellent Anti-oxidation stability, the effect of improving the film-forming mechanism of the emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

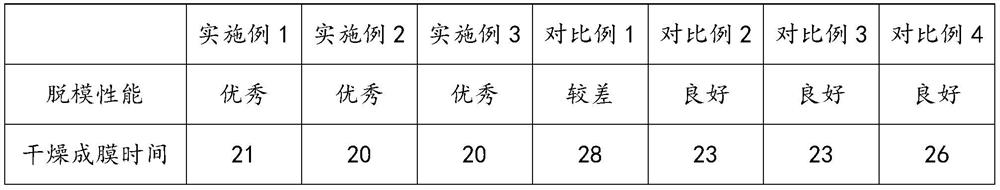

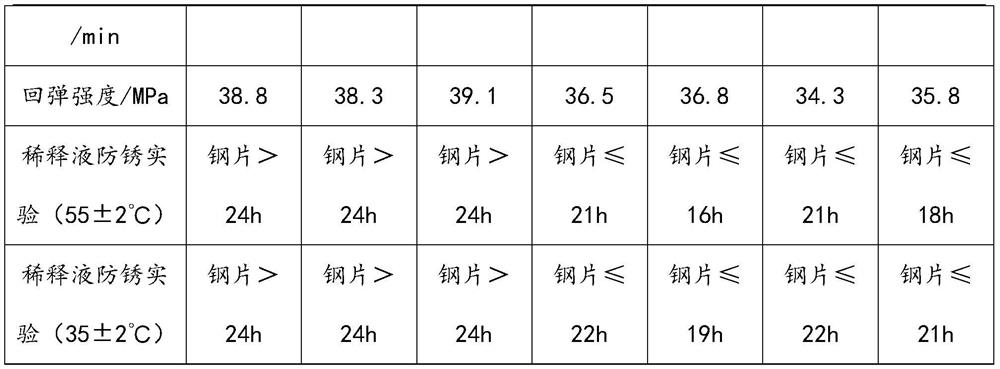

Examples

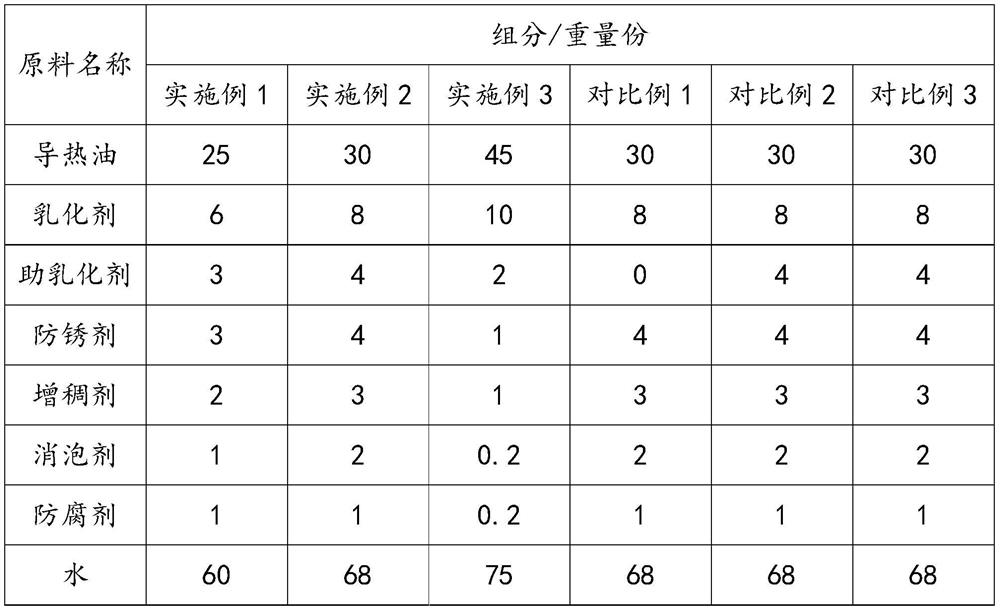

Embodiment 1

[0042] In parts by weight, the specific steps are as follows:

[0043] (1) Mix 25 parts of waste heat transfer oil, 60 parts of water, 2 parts of sorbitan monostearate, 1 part of polyoxyethylene sorbitan trioleate, 3 parts of polyoxyethylene sorbitan trioleate The stearic acid ester was added into the reaction kettle and stirred for 30 minutes under the condition of 2800r / min to obtain pre-emulsified oil.

[0044] (2) Add 1 part of diisobutyl succinate, 1 part of diisobutyl glutarate and 1 part of diisobutyl adipate into the reaction kettle and stir at 2800r / min for 30min to obtain completely emulsified oil .

[0045] (3) Add 1 part of oleic acid into the reaction vessel and heat until melted, then slowly add 1 part of triethanolamine, react at 55°C for 4 hours at 100 r / min, add 1 part of sodium nitrite and 1 part of sodium carbonate after cooling, and obtain Rust inhibitor.

[0046] (4) Add 3 parts of antirust agent, 2 parts of thickener, 1 part of defoamer and 1 part of p...

Embodiment 2

[0048] In parts by weight, the specific steps are as follows:

[0049] (1) Mix 30 parts of waste heat transfer oil, 68 parts of water, 2 parts of sorbitan monostearate, 2 parts of polyoxyethylene sorbitan trioleate, 4 parts of polyoxyethylene sorbitan trioleate The stearic acid ester was added into the reaction kettle and stirred for 30 minutes under the condition of 2800r / min to obtain pre-emulsified oil.

[0050] (2) Add 1 part of diisobutyl succinate, 1 part of diisobutyl glutarate and 2 parts of diisobutyl adipate into the reaction kettle and stir at 2800r / min for 30min to obtain a fully emulsified oil .

[0051] (3) Add 2 parts of oleic acid into the reaction vessel and heat until melted, then slowly add 2 parts of triethanolamine, react at 55°C, 100r / min for 4h, add 2 parts of sodium nitrite and 2 parts of sodium carbonate after cooling, and obtain Rust inhibitor.

[0052] (4) Add 4 parts of antirust agent, 3 parts of thickener, 2 parts of defoamer and 1 part of prese...

Embodiment 3

[0054] In parts by weight, the specific steps are as follows:

[0055](1) Mix 45 parts of waste heat transfer oil, 75 parts of water, 3 parts of sorbitan monostearate, 3 parts of polyoxyethylene sorbitan trioleate, 4 parts of polyoxyethylene sorbitan trioleate The stearic acid ester was added into the reaction kettle and stirred for 30 minutes under the condition of 2800r / min to obtain pre-emulsified oil.

[0056] (2) Add 0.5 part of diisobutyl succinate, 0.5 part of diisobutyl glutarate and 1 part of diisobutyl adipate into the reaction kettle and stir for 30 minutes at 2800 r / min to obtain fully emulsified oil .

[0057] (3) Add 2 parts of oleic acid into the reaction vessel and heat until melted, slowly add 2 parts of triethanolamine, react at 60°C, 100r / min for 4h, add 2 parts of sodium nitrite and 2 parts of sodium carbonate after cooling, and obtain Rust inhibitor.

[0058] (4) Add 1 part of antirust agent, 1 part of thickener, 0.2 part of defoamer and 0.2 part of pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com