Alginate antibacterial composite film and preparation method thereof

An alginate and composite membrane technology, applied in the manufacture of rayon, conjugated rayon, chemical characteristics of fibers, etc., can solve the problems of bulging or deformation, unstable concentration of bacteriostatic substances, low safety, etc. Effects of stability and renaturation, good overall shape retention, and good bacteriostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

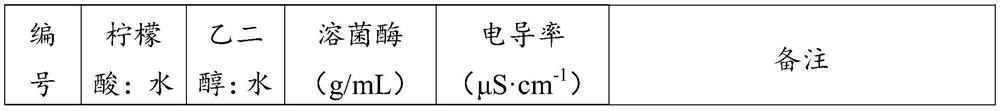

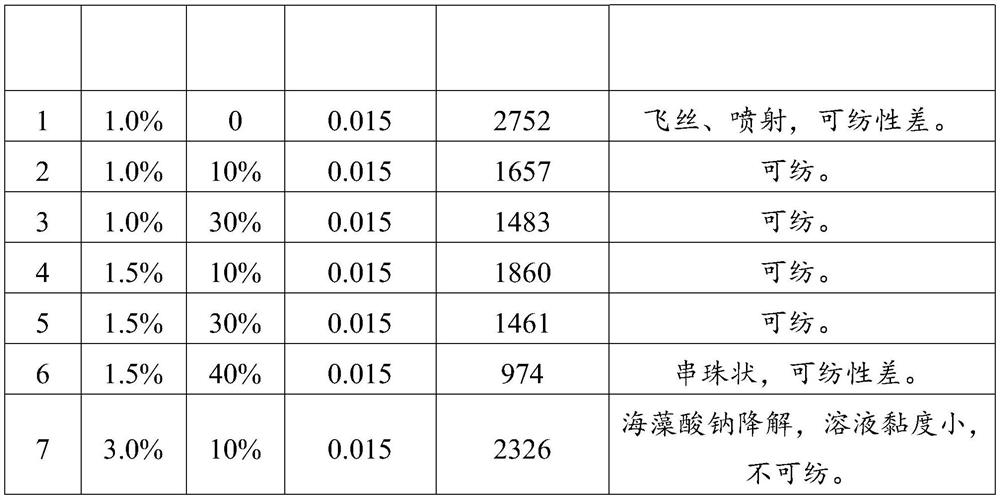

[0025] As a kind of alginate antibacterial composite membrane of the embodiment of the present invention, described alginate antibacterial composite membrane is obtained by cross-linking the nanocellulose membrane of double-layer structure, and the nanocellulose membrane of described double-layer structure is obtained by electrospinning The shell liquid and the electrospinning core liquid are obtained by coaxial electrospinning, and the electrospinning shell liquid includes chitosan, sodium alginate, lysozyme and solvent A, and the solvent A is the mixture of lemon, ethylene glycol and water. Mixed solution; the weight ratio of citric acid, ethylene glycol and water in solvent A is 1.0:10:100, and the electrospinning core solution includes bioactive glass, agarose acetate and an organic solvent, and the organic solvent is chloroform ;

[0026] The concentration of chitosan and sodium alginate in the electrospinning shell solution is 0.02g / mL; the mass ratio of chitosan and sod...

Embodiment 2

[0034] As an alginate antibacterial composite film in the embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is: the concentration of bioactive glass in the electrospinning core liquid is 0.05g / mL, and the concentration of the electrospinning core liquid is 0.05g / mL. The mass concentration of agarose acetate in the silk core solution was 0.10 g / mL.

Embodiment 3

[0036] As an alginate antibacterial composite film of the present invention, the only difference between this example and Example 1 is that the weight ratio of citric acid, ethylene glycol and water in solvent A is 1.0:30:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com