Grain drying dehumidifying heat pump unit and grain drying circulation heat pump system

A technology of grain drying and heat pump system, applied in dryers, drying gas arrangement, drying and other directions, can solve the problems of difficulty in starting the system, limited energy saving, decreased drying efficiency, etc. Too high, the effect of preventing the supply air temperature from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

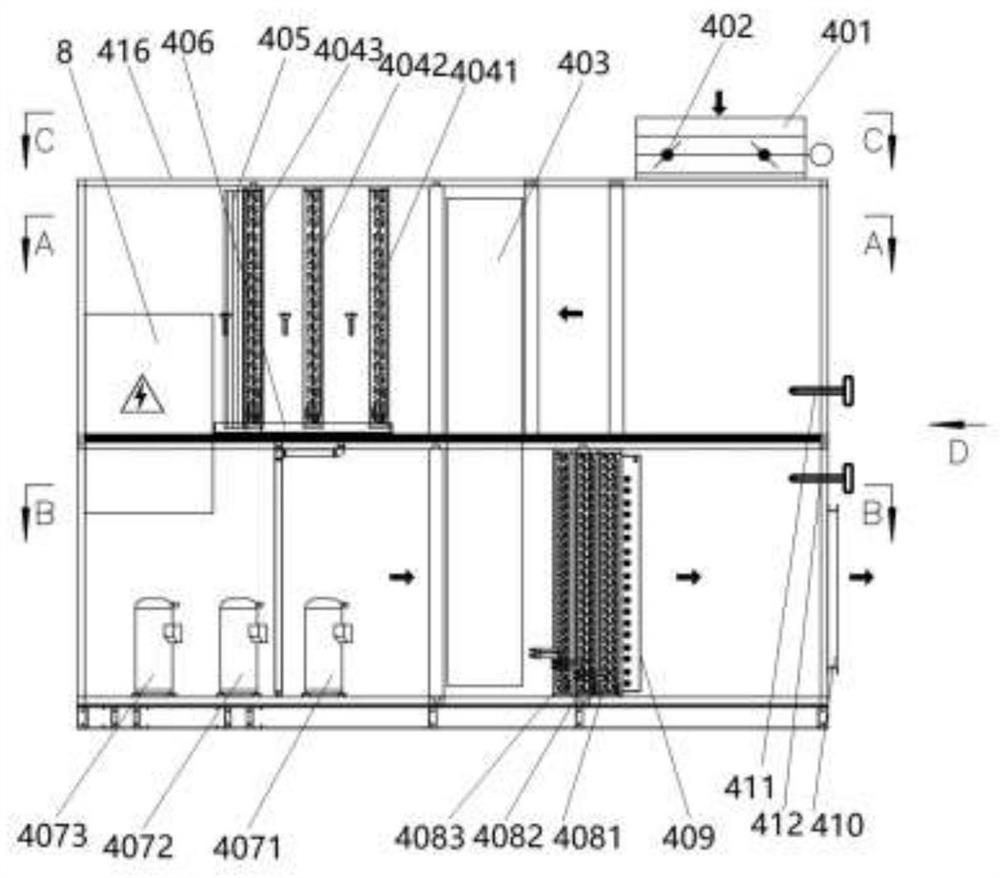

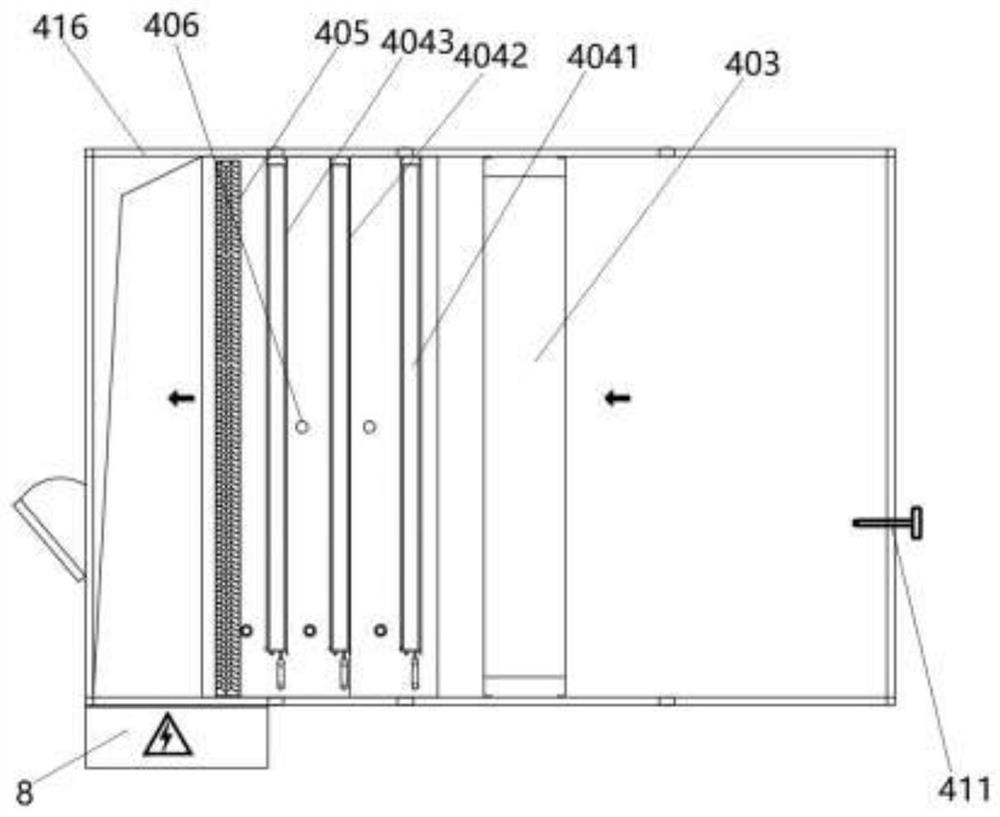

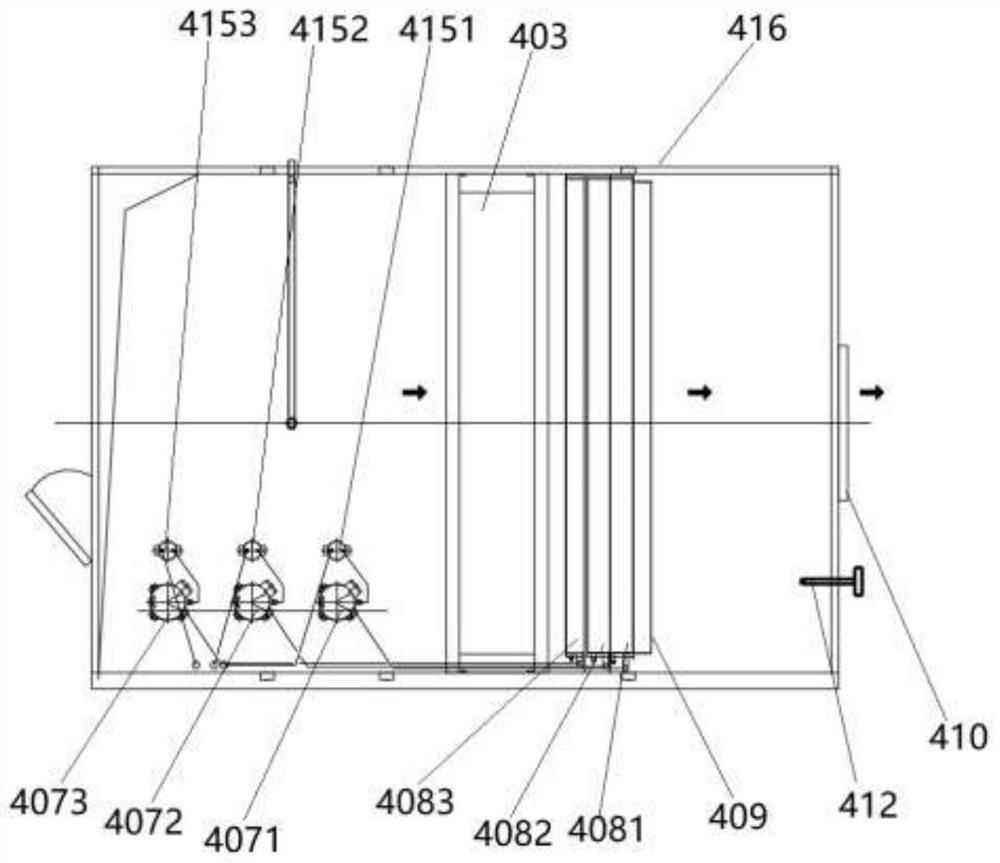

[0022] Such as Figure 1 to Figure 3As shown, the grain drying and dehumidifying heat pump unit 4, hereinafter referred to as "the device". The device includes an upper and lower layered chassis 416, three sets of independently working heat pump systems installed in the chassis 416, an air inlet 401, an electric air inlet valve 402, an inlet air temperature and humidity sensor 411, and a sensible heat rotary heat exchanger 403, water baffle 405, condensed water tray and water pipe 406, auxiliary electric heater 409, air supply port 410, air supply temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com