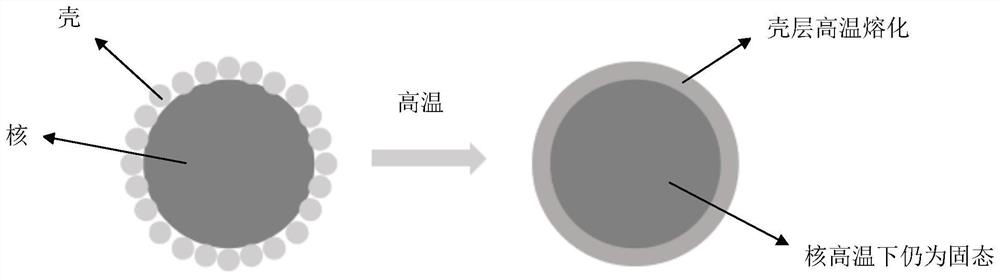

Method for assisting grain boundary diffusion of heavy rare earth elements through low-melting-point metal or alloy

A technology of low-melting-point metals and heavy rare-earth elements, which is applied in the manufacture of electrical components, inductors/transformers/magnets, circuits, etc., and can solve the problems of high process control accuracy and unfavorable large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

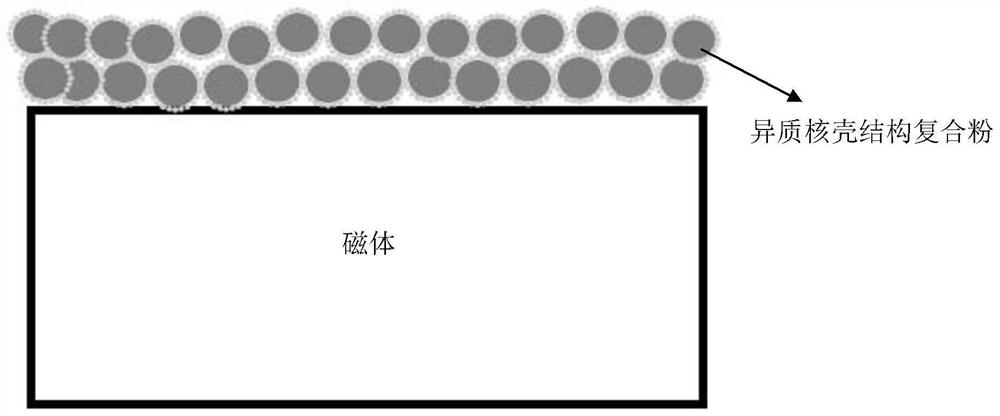

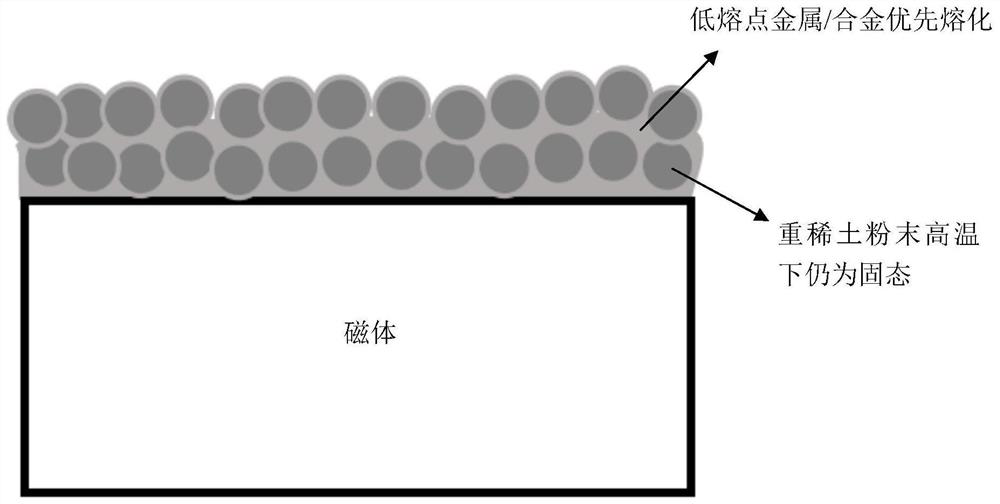

Embodiment 1

[0045] Configure the atomic percentage as Pr 80 al 20 The raw materials are smelted into alloy ingots by means of electric arc melting, and the melted alloy ingots are broken into small pieces, which are made into strips by rapid quenching, and then crushed into larger-sized powders. with a particle size of 10 μm DyF 3 After the powders were mixed in a 1:1 ratio, they were ball milled for 3 hours under the protection of ethanol at a speed of 300r / min (after filtration DyF 3 powder can be reused). The purposeful use of mechanical stress on Pr 80 al 20 The surface of the alloy powder is activated to make the surface adsorb DyF 3 powder. Thus prepared Pr with a particle size of 20 μm 80 al 20 The surface of the alloy powder is coated with a layer of DyF with a particle size of 800nm 3 powder. Mix the prepared heterogeneous core-shell structure composite powder diffusion source with alcohol and citric acid monohydrate to prepare a slurry, and uniformly cover the upper an...

Embodiment 2

[0050] Put the Tb metal with a purity of 99.7% into the hydrogen breaking furnace, hydrogen crushing at 300°C for 3 hours, and dehydrogenation at 500°C for 3 hours. Prepared TbH with slightly larger particle size 2 meal. TbH 2 The coarse powder was put into a ball mill and ball milled at 200 r / min for 3 hours to prepare a powder with a particle size of 5 μm. Due to TbH 2 The fine powder has limited oxidation resistance and is flammable. The above work must be carried out in a glove box.

[0051] Using Cu powder with a particle size of 500nm to assist TbH 2 Grain boundary diffusion, according to Cu:TbH 2 : Alcohol = 1:1:1 ratio to mix the slurry, put the slurry in alcohol and shake for 30 minutes, so that the Cu nano powder is adsorbed on the TbH 2 Powder surface.

[0052] Immerse the polished magnet in the slurry for 2-3 seconds, then take it out and dry it with argon, repeat 3 times. Put the processed magnet into the sintering furnace, the vacuum degree is lower than ...

Embodiment 3

[0056] Configure the atomic percentage as La 75 al 25 The raw materials are smelted into alloy ingots by arc melting, the melted alloy ingots are broken into small pieces, made into strips by rapid quenching, and ground into 200μm thick strips under the protection of argon gas. Powder (La 75 al 25 The antioxidant capacity is weak, so it is ground into coarse powder).

[0057] Thanks to La 75 al 25 The anti-oxidation ability is weak, and it is more suitable to adopt the method of polymer coating, and DyF 3 Inorganic substances have good compatibility with polyvinyl butyral (PVB), and DyF with a particle size of 2 μm 3 The powder can be evenly dispersed in PVB alcohol solution. Therefore, the polymer coating method was used to treat La 75 al 25 alloy powder for DyF 3 And double-layer coating of PVB. This method is simple to operate, easy to operate, has strong anti-oxidation ability, and the way of brushing the slurry can be carried out under the air, which reduces th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com