Degradable medical film and preparation method thereof

A film and medical technology, applied in the field of degradable medical film and its preparation, can solve the problems of poor stretchability, poor adhesion of tissue patches, uncontrollable degradation time, etc., and achieve strong adhesion, easy drying process, and solvent The effect of low residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

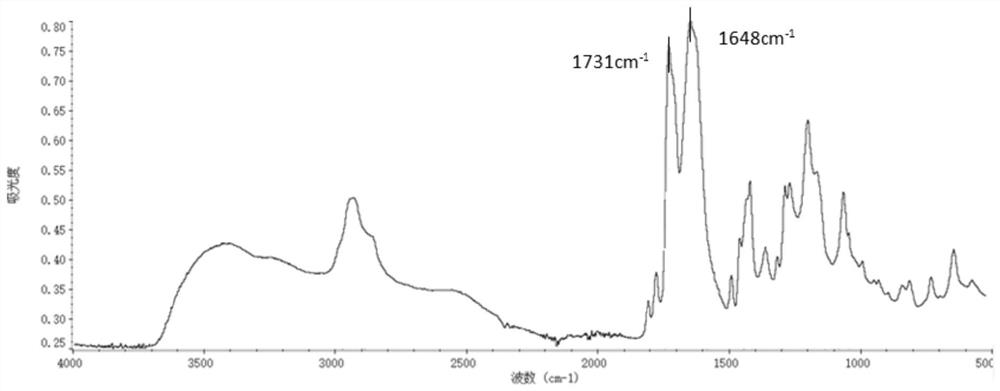

[0072]First, the synthesis of the biological tissue adhesive material can be degraded

[0073]Step 1: Add Acrylic (AAC) 5 mol, N-vinyl-2-pyrrolidone (NVP) 5 mol, azo diisobutyronitrile (AIBN) 6g, and dimethyl sulfoxide 10L, and the reaction kettle is added to 70 ° C, Continuous reaction for 12 hours; the reaction is as follows:

[0074]

[0075]Step 2: Start cooling, set the temperature of 25 ° C, add N-hydroxy succinimide 2.5 mol, bicyclic hexyl carbon diimide (DCC) 3 mol within the reactor, continued to react 48 hours; the reaction formula is as follows:

[0076]

[0077]Step 3: After the reaction is completed, the material is filtered, and the filter cake is filtered, and the filtrate is retained, the synthesized trimer remains in the filtrate to obtain the first crude product.

[0078]Step 4: The first crude product was slowly added dropwise to 100 L of ethyl acetate to obtain a second crude product; the purpose of this step was coarse washed (purified) to obtain a trimer solid.

[0079]The method o...

Embodiment 2

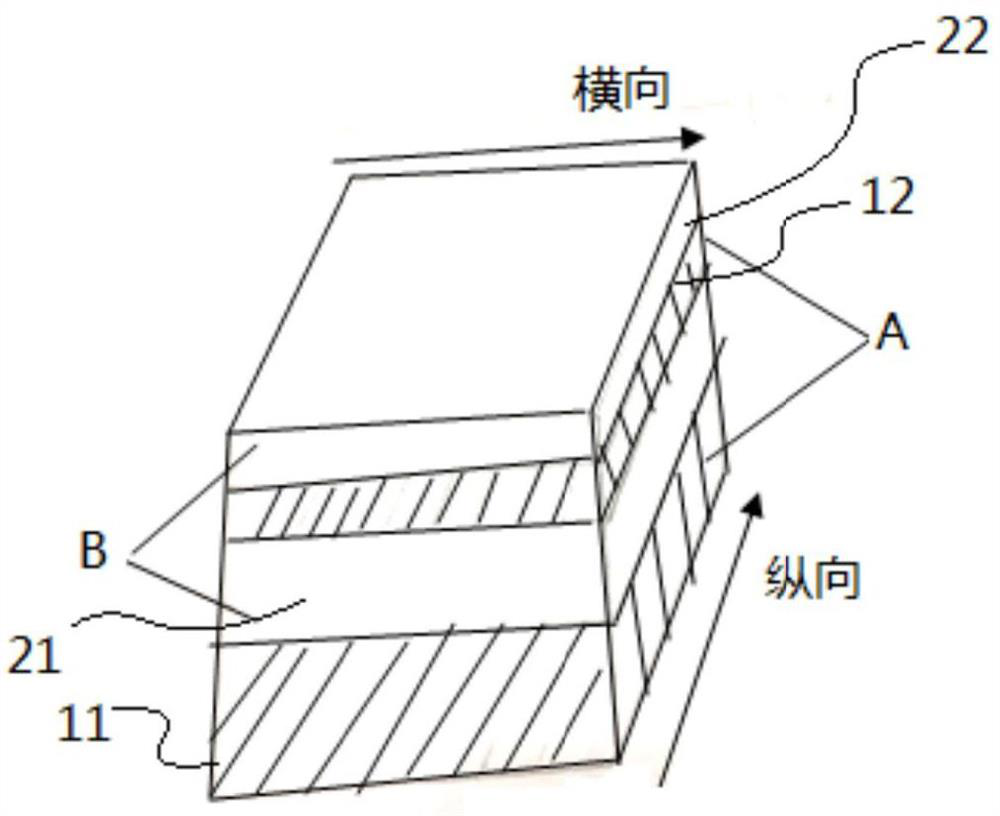

[0091]Example 2 (a small amount of multiple coating film)

[0092]According to the clinical needs and convenient production operation, a small amount of multiple coating film can be taken, using an ABAB structure, a small amount of multi-level coating method, the drying process is relatively easier, so that the solvent residue is lower, and the safety requirements of medical devices can be in line with the safety requirements of medical equipment. .

[0093]I. Synthesis of degradable biological tissue adhesive materials

[0094]Synthesis of the degradable biological tissue adhesive material in Example 1.

[0095]Second. Making film (coating film)

[0096]Step 1, dissolve the substrate layer material polylactic acid (PLGA, monomer ratio 85:15, viscosity 0.8) in dichloromethane, configure a mass fraction of 5% -10% of the PLGA solution; the degradable organism prepared The tissue adhesive material is dissolved in a mixed solvent having a volume ratio of 3: 1 dichloromethane with methanol, and the ma...

Embodiment 3

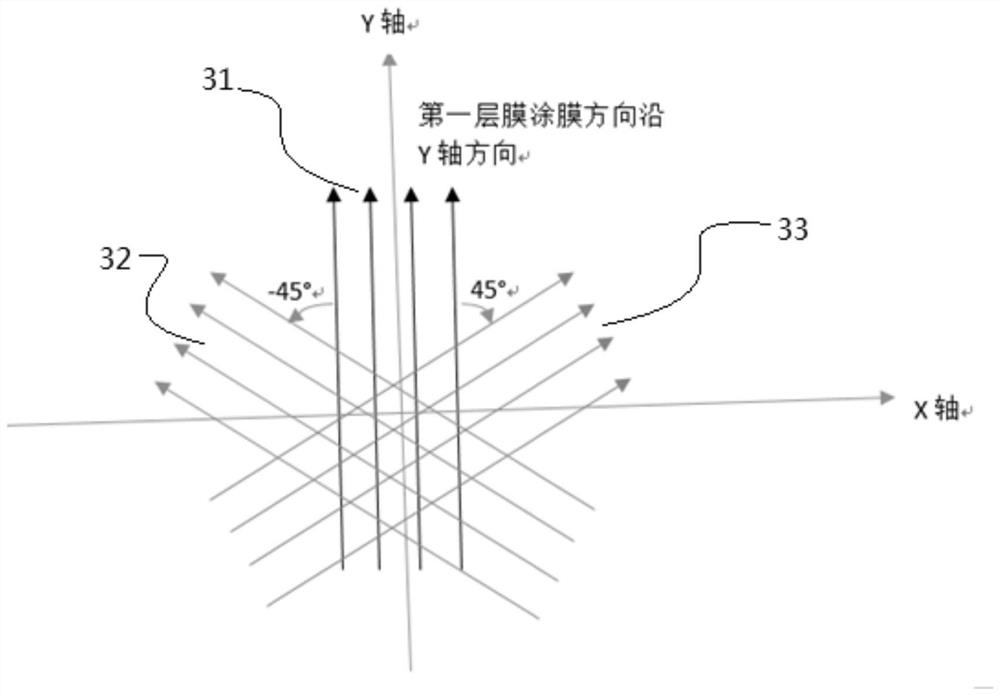

[0102]The method is coated in the first direction, and the first adhesion layer (second film) is coated in the second direction, the second direction and the first The angle in one direction is 90 °; the second support layer (third film) is disposed along the third direction, the third direction and the angle of the first direction are -90 °; the second adhesion layer (No. The 4-layer film is provided in the fourth direction, the fourth direction is 0 ° in the first direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com