Internal moving type high-strength pervious concrete

A permeable concrete and high-strength technology, applied in the field of building materials, can solve the problems of poor water permeability, low strength, and drainage effect of permeable concrete depending on the quality of the pores formed in the concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] see figure 1 , an internal high-strength permeable concrete, including the following raw materials in parts by weight: 15 parts of ordinary portland cement, 0.2 parts of reinforcing fiber, 10 parts of granite crushed stone, 5 parts of water seepage filler, 4 parts of pebbles, porous fine 60 parts of aggregate, 2 parts of hydrophilic white carbon black, 3 parts of water, 0.5 parts of water reducer and 5 parts of internal dynamic microspheres.

[0040] One or more of carbon nanofibers, steel fibers, nylon fibers, polypropylene fibers, polyethylene fibers.

[0041] The seepage filler is made by washing and drying river sand, crushing it to 60-80 mesh, and mixing it with bentonite.

[0042] The porous fine aggregate is 40-80 mesh fine aggregate obtained by screening industrial waste slag after high-temperature smelting and calcination. The calcination temperature for high-temperature calcination is 1250-1350°C, and the calcination time is 25-35min.

[0043] The water redu...

Embodiment 2

[0050] An internal high-strength permeable concrete, comprising the following raw materials in parts by weight: 18 parts of ordinary Portland cement, 0.3 parts of reinforcing fiber, 12 parts of granite crushed stone, 6 parts of permeable filler, 6 parts of pebbles, porous fine bone 65 parts of raw material, 3 parts of hydrophilic white carbon black, 4 parts of water, 1.2 parts of water reducing agent and 6 parts of internal dynamic microspheres.

[0051] The rest are consistent with Example 1.

Embodiment 3

[0053] An internal high-strength permeable concrete, comprising the following raw materials in parts by weight: 20 parts of ordinary Portland cement, 0.4 parts of reinforcing fiber, 15 parts of granite gravel, 8 parts of water seepage filler, 8 parts of pebbles, porous fine bone 70 parts of raw material, 4 parts of hydrophilic white carbon black, 6 parts of water, 2 parts of water reducer and 8 parts of internal dynamic microspheres.

[0054] The rest are consistent with Example 1.

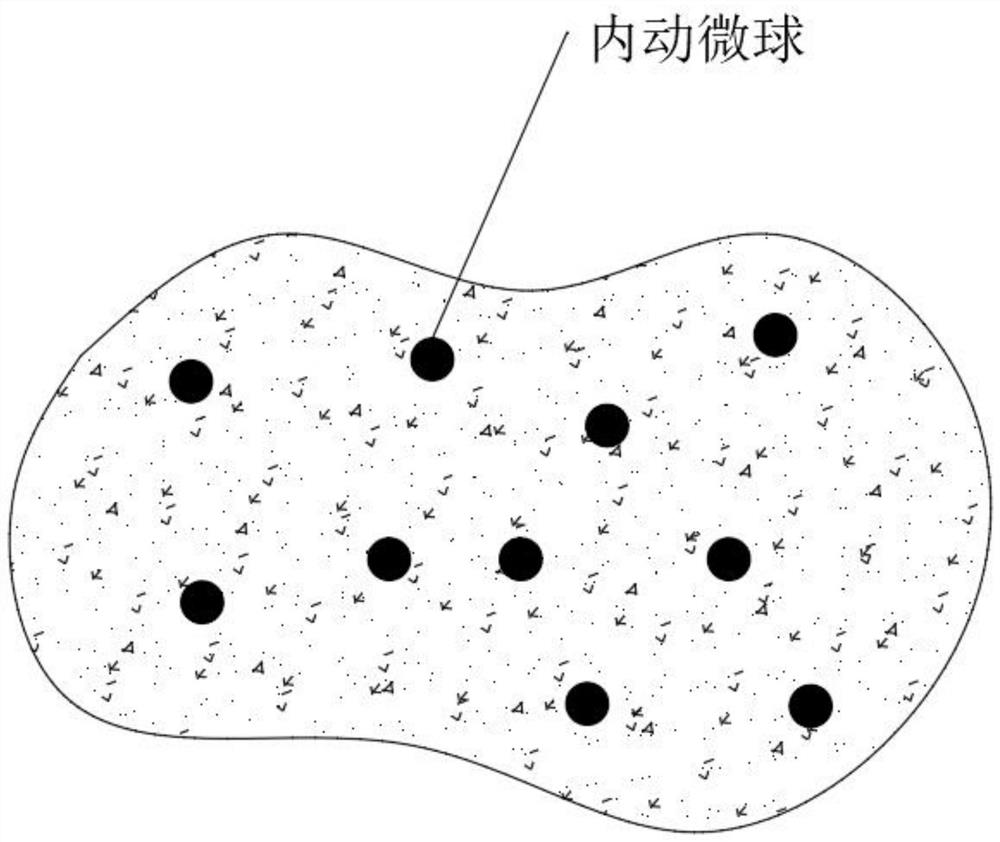

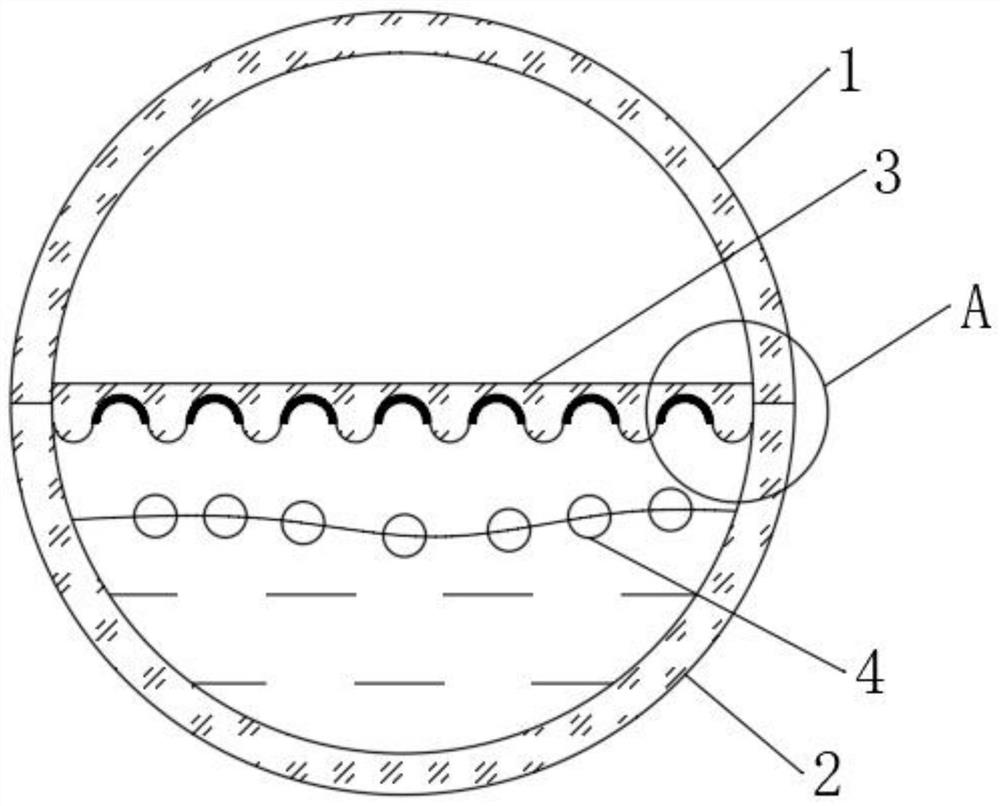

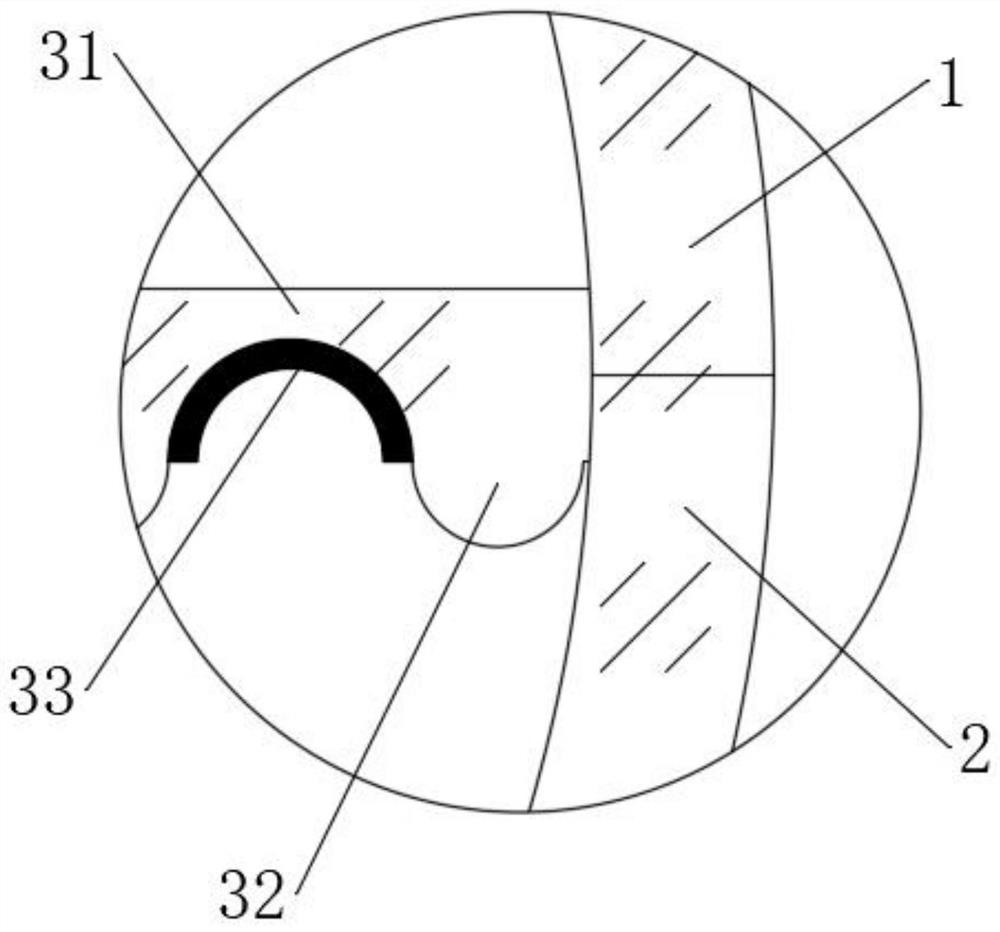

[0055] The invention can significantly improve the water permeability and strength of the permeable concrete by improving the raw materials of the permeable concrete, introducing reinforcing fibers, water-permeable fillers, porous fine aggregates and hydrophilic silica, and innovatively introducing internal moving microspheres Pre-embedded in pervious concrete, on the one hand, it can act as part of the coarse aggregate, which can not only increase the porosity of pervious concrete, but also assis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com