Method for producing microalgae grease by using flue gas

A microalgal oil and flue gas technology, applied in the fields of biotechnology and bioenergy, can solve the problem of limited SOx removal effect, and achieve the effects of promoting endurance improvement, increasing oil production, and high carbon sequestration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

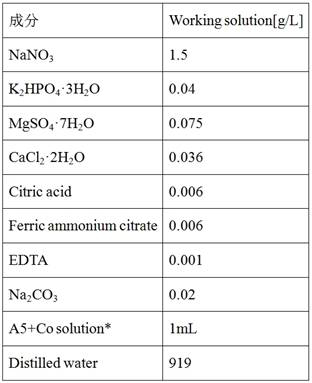

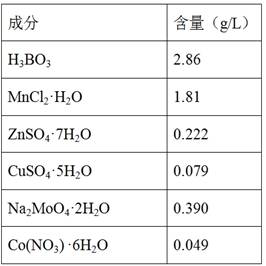

Embodiment 1

[0038] Add 8L BG11 microalgae culture medium, 400mL Scenedesmus HY-D3 seed liquid and 400mL Chlorella SF-B1 seed liquid into a 20L photobioreactor, and pass CO 2 Volume content is 40v%, NO volume content is 0.08%, SO 2 Flue gas with a volume content of 0.06%, 300mL Scenedesmus obliquus FSH-Y2 seed solution was added at one time after 24 hours of cultivation. The culture temperature of the control culture system was 25°C, the light cycle was 24h, the light-dark time ratio was 14:10, and the light intensity was 10000Lux. After culturing for 7 days, the culture was terminated, the algae liquid was collected by centrifugation, and the dry weight of the algae powder was measured after vacuum freeze-drying at -60°C to a constant weight, and the biomass production was calculated, and the total lipid content was measured by the n-hexane:ethyl acetate method . After testing, the dry cell weight can reach 12.3g / L, and the oil content is 46.5% of the dry cell weight. After detection a...

Embodiment 2

[0040] Add 8L BG11 microalgae culture medium, 800mL Scenedesmus HY-D3 seed liquid and 800mL Chlorella SF-B1 seed liquid into a 20L photobioreactor, and pass CO 2 Volume content is 40v%, NO volume content is 0.08%, SO 2 With a volume content of 0.06% flue gas, 200 mL of Scenedesmus obliquus FSH-Y2 seed solution was added at one time after 12 hours of cultivation. The culture temperature of the control culture system was 35°C, the light cycle was 24h, the light-dark time ratio was 14:10, and the light intensity was 10000Lux. After culturing for 7 days, the culture was terminated, the algae liquid was collected by centrifugation, and the dry weight of the algae powder was measured after vacuum freeze-drying at -60°C to a constant weight, and the biomass production was calculated, and the total lipid content was measured by the n-hexane:ethyl acetate method . After testing, the dry cell weight can reach 12.5g / L, and the oil content is 47.5% of the dry cell weight. After detecti...

Embodiment 3

[0042] Add 8L BG11 microalgae medium, 600mL Scenedesmus HY-D3 seed liquid and 200mL Chlorella SF-B1 seed liquid into a 20L photobioreactor, and pass CO 2 Volume content is 40v%, NO volume content is 0.08%, SO 2 With a volume content of 0.06% flue gas, 400 mL of Scenedesmus obliquus FSH-Y2 seed solution was added at one time after 48 hours of cultivation. The culture temperature of the control culture system was 20°C, the light cycle was 24h, the light-dark time ratio was 14:10, and the light intensity was 10000Lux. After culturing for 7 days, the culture was terminated, the algae liquid was collected by centrifugation, and the dry weight of the algae powder was measured after vacuum freeze-drying at -60°C to a constant weight, and the biomass production was calculated, and the total lipid content was measured by the n-hexane:ethyl acetate method . After testing, the dry cell weight can reach 12.1g / L, and the oil content is 46.2% of the dry cell weight. After detection and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com