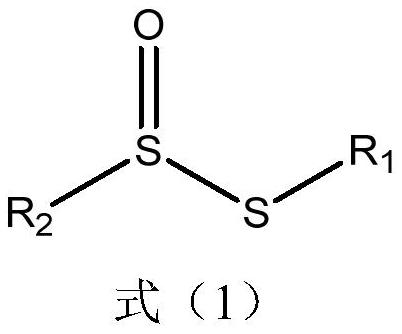

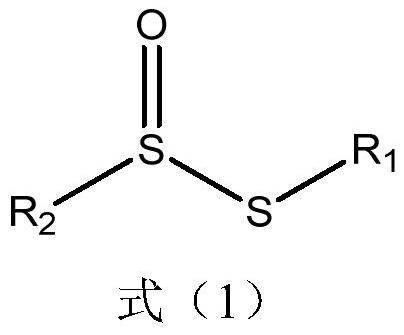

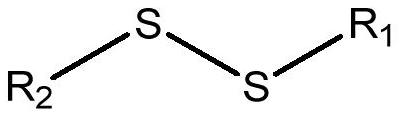

Method for inhibiting infectious microbe reproduction in spirulina cultivation process by using diprimary/secondary alkyl thiosulfinate

The technology of secondary alkyl thiosulfinic acid ester and secondary alkyl thiosulfinic acid is applied in the field of aquaculture and production, and can solve the problems of weak penetration, low feasibility, destruction of nutrient components and the like, To achieve the effect of increasing economic benefits and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of di-n-pentyl thiosulfinate:

[0028] Add di-n-pentyl disulfide in dichloromethane-methanol (dichloromethane to methanol volume ratio is 90:10) according to the molar concentration of 50mol / L, and add dimethyl selenate according to the molar concentration of 5mol / L ester; then add hydrogen peroxide according to 20mol / L, and stir the reaction at 25°C for 5 hours. After the reaction was finished, the reaction mixture was washed three times with three volumes of saturated sodium chloride solution. The product was obtained after the reaction mixture was dried under vacuum at 35 °C. The content of di-n-pentylthiosulfinate in the product was 90%.

[0029] Material Characterization: m / z 222.11; 1 HNMR (deuterated DMSO): δ=0.8ppm (triplet, 6H, -CH 3 ), 1.28~1.50ppm (multiple peaks, 12H, -CH 2 ), 2.4ppm (triplet, 2H, -CH 2 -S-), 2.5ppm (triplet, 2H, -CH 2 -S=O).

[0030] (2) Use di-n-pentyl thiosulfinate to inhibit the growth of miscellaneous bacteria in...

Embodiment 2

[0034] (1) Preparation of di-n-octyl thiosulfinate:

[0035] Add di-n-octyl disulfide (purchased from Shanghai Hansi Chemical Co., Ltd.) in dichloromethane-methanol (the volume ratio of dichloromethane and methanol is 80:20) according to the molar concentration of 35mol / L, according to the molar concentration Add dimethyl selenate at 3 mol / L; then add hydrogen peroxide at 40 mol / L, then stir and react at 50°C for 10 hours. After the reaction was finished, the reaction mixture was washed three times with three volumes of saturated sodium chloride solution. The product was obtained after the reaction mixture was dried under vacuum at 55 °C. The content of di-n-octylthiosulfinate in the product was 75%.

[0036] Material Characterization: m / z 306.21; 1 HNMR (deuterated DMSO): δ=0.88ppm (triplet, 6H, -CH 3 ), 1.21~1.50ppm (multiple peaks, 24H, -CH 2 ), 2.4ppm (triplet, 2H, -CH 2 -S-), 2.5ppm (triplet, 2H, -CH 2 -S=O).

[0037] (2) Use di-n-octyl thiosulfinate to inhibit th...

Embodiment 3

[0041] (1) Preparation of diisoamyl thiosulfinate:

[0042] In dichloromethane-methanol (the volume ratio of dichloromethane and methanol is 100:0) solution, add diisoamyl disulfide according to the molar concentration of 45mol / L, add dimethyl selenate according to 4mol / L; then After adding hydrogen peroxide at a rate of 15 mol / L, the mixture was stirred and reacted at 45° C. for 3 hours. After the reaction, the reaction mixture was washed three times with three volumes of saturated sodium chloride (purchased from Sinopharm Chemical Reagent Co., Ltd.) solution. The product was obtained after the reaction mixture was dried under vacuum at 35 °C. The content of diisoamylthiosulfinate in the product was 80%.

[0043] Material Characterization: m / z 222.11; 1 HNMR (deuterated DMSO): δ=0.93~0.99ppm (multiple peaks, 12H, -CH 3 ), 1.55ppm (multiplet, 4H, -CH 2 ), 1.77ppm (multiplet, 2H, -CH), 2.36ppm (2H, -CH 2 -S-), 2.62ppm (2H, -CH 2 -S=O).

[0044] (2) Use diisoamyl thiosul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com