A kind of preparation method of znfe-ldhs/diatomite composite material

A technology of composite materials and diatomite, applied in chemical instruments and methods, improvement of process efficiency, other chemical processes, etc., can solve the problem of diatomite attachment vacancy occupation, reduction of diatomite surface area, low fluorine adsorption capacity, etc. problems, achieve the effect of eliminating structural water and non-bridging hydroxyl groups, improving fluorine adsorption capacity, and high fluorine adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

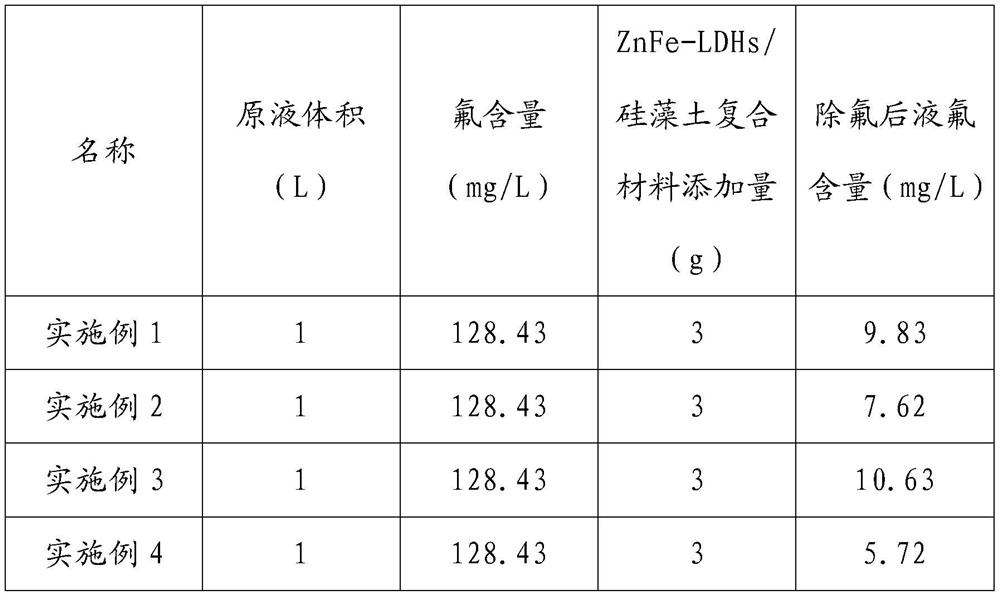

Examples

Embodiment 1

[0026] The present embodiment provides a preparation method of ZnFe-LDHs / diatomite composite material, and the specific process is:

[0027] (1) Place diatomite in a beaker and add sulfuric acid solution, stir for 4h under the conditions of liquid-solid ratio (volume / mass) 4:1, solution temperature 40°C, and sulfuric acid concentration 0.5mol / L, and filter to obtain The diatomite was washed with water until the washing water became neutral, and then air-dried to constant weight.

[0028] (2) The acidified diatomite was calcined at a calcination temperature of 350° C. for 2 h to obtain calcined activated diatomite.

[0029] (3) using zinc nitrate and ferric nitrate to prepare a mixed solution of zinc and iron, the mass concentrations of zinc nitrate and ferric nitrate are 4% and 2% respectively.

[0030] (4) the activated diatomite is placed in the container containing the zinc-iron mixed solution according to the solid-liquid ratio (mass / volume) 1:100, and the pH is adjusted ...

Embodiment 2

[0033] The present embodiment provides a preparation method of ZnFe-LDHs / diatomite composite material, and the specific process is:

[0034] (1) Acidification modification Put diatomite in a beaker and add sulfuric acid solution, stir for 4 hours under the conditions of liquid-solid ratio (volume / mass) 10:1, solution temperature 70 °C, and sulfuric acid concentration 1.1 mol / L, filter , the obtained diatomite is washed with water until the washing water is neutral, and then air-dried to constant weight.

[0035] (2) calcining the acidified diatomite at a calcination temperature of 550° C. for 3 hours to obtain calcined activated diatomite.

[0036] (3) using zinc acetate and ferric sulfate to prepare zinc-iron solution, the mass concentrations of zinc acetate and ferric sulfate are 6% and 2.5% respectively.

[0037] (4) The activated diatomite is placed in the container containing the zinc-iron mixed solution according to the solid-liquid ratio (mass / volume) 1:50, and the pH ...

Embodiment 3

[0040] The present embodiment provides a preparation method of ZnFe-LDHs / diatomite composite material, and the specific process is:

[0041] (1) Place diatomite in a beaker and add sulfuric acid solution, stir for 6 h under the conditions of liquid-solid ratio (volume / mass) 8:1, solution temperature 60 °C, and sulfuric acid concentration 0.3 mol / L, and filter to obtain The diatomite was washed with water until the washing water became neutral, and then air-dried to constant weight.

[0042](2) The acidified diatomite was activated at a microwave frequency of 4000 MHz for 25 min to obtain microwave-activated diatomite.

[0043] (3) The zinc-iron solution is prepared by using zinc sulfate and iron nitrate, and the mass concentrations of zinc sulfate and iron nitrate are 0.8% and 0.4%, respectively.

[0044] (4) the diatomite after activation modification is placed in the container that is housed with the zinc-iron mixed solution according to the solid-liquid ratio (mass / volume)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com