Coupling method for converting lactic acid from water-containing raw material of lactate and extracting lactic acid

A lactate and raw material technology, applied in the production and conversion of lactic acid, can solve the problems of low conversion rate, solid waste conversion conditions, harsh conditions, etc., and achieve high conversion rate, low operating pressure and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

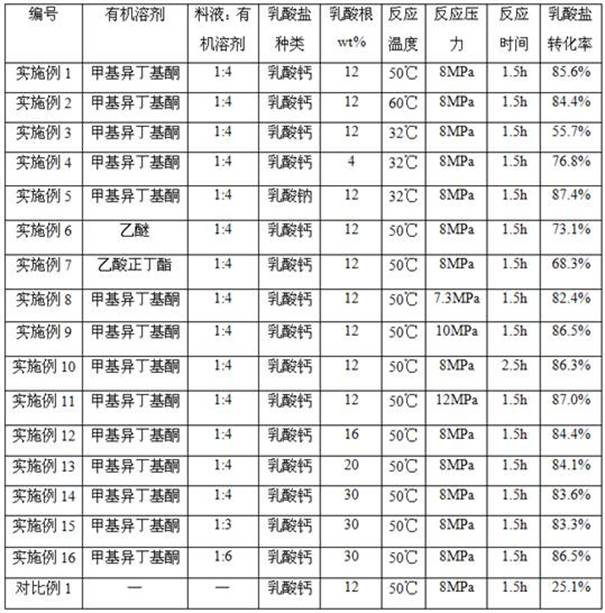

Examples

Embodiment 1

[0029] Get the aqueous feed liquid 100g that contains calcium lactate through sterilizing treatment and add reactor, wherein the massfraction of lactate radical in aqueous feed liquid is 12%, to wherein adding organic solvent methyl isobutyl ketone 400g, then to reactor Carbon dioxide was filled in the medium and the pressure was increased to 8MPa, the temperature was raised to 50°C, and the reaction was fully stirred at constant temperature and pressure for 1.5h. After the reaction, the reaction liquid is left to stand and stratified, and the organic phase is transferred to the buffer tank that is pre-pressurized to the same pressure as the reactor through the side line pipeline at the height of the phase interface of the reactor, so as to realize the liquid separation of the inorganic phase, and then reduce the temperature and pressure , carbon dioxide is recovered, and lactic acid is dissolved in the organic phase. Then, the lactic acid is separated by the method of aqueous...

Embodiment 2

[0031] Except changing reaction temperature into 60 ℃, other conditions are identical with embodiment 1.

Embodiment 3

[0033] Except changing reaction temperature into 32 ℃, other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com