A method for coupled transformation and extraction of lactic acid from aqueous feedstock of lactate

A lactate and raw material technology, applied in the field of coupled conversion and extraction of lactic acid, can solve the problems of low conversion rate, harsh conversion conditions, and solid waste generation, achieve high conversion rate, simplify post-treatment process, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

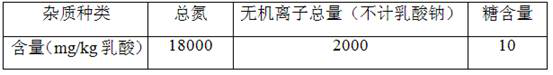

[0031] The sodium lactate fermentation broth was treated by sterilization, decolorization and ultrafiltration, wherein the mass fraction of lactate in the aqueous feed liquid was 12%. The content of impurities in the treated sodium lactate fermentation broth is shown in Table 1.

[0032] Table 1.

[0033]

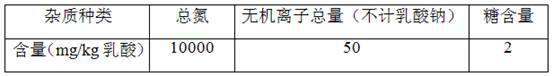

[0034] Get the above-mentioned treated sodium lactate fermentation liquid 100g and add it to the reactor, then add 48g of solid adsorbent PVP resin (in terms of the dry basis weight of the resin), that is, 4 times the weight of lactate in the feed liquid, then fill the reactor with Carbon dioxide and pressurized to 8.0MPa, control the temperature to 10 ℃, maintain constant temperature and pressure to fully stir the reaction for 2h. After that, the feed liquid was discharged to the buffer tank, depressurized and recovered carbon dioxide, washed the solid adsorbent with a sufficient amount of 5 ℃ pure water, retained the washing liquid, and measured the residual lactic ac...

Embodiment 2

[0036] Other conditions were the same as in Example 1, except that the solid adsorbent was replaced with an equal weight of D301 resin.

Embodiment 3

[0038] Other conditions were the same as in Example 1, except that the solid adsorbent was replaced with an equal weight of DR2 resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com