Epoxy resin curing agent, preparation method, epoxy resin composition and application

An epoxy resin curing and epoxy resin technology, which is applied to epoxy resin compositions and their application fields in casting parts, epoxy resin curing agents, and electronic and electrical casting parts, can solve the problem of reducing the strength of casting materials and easily occurring Breaking, peeling, heat can not be released in time and other problems, to solve the problem of core burning, avoid local overheating core burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

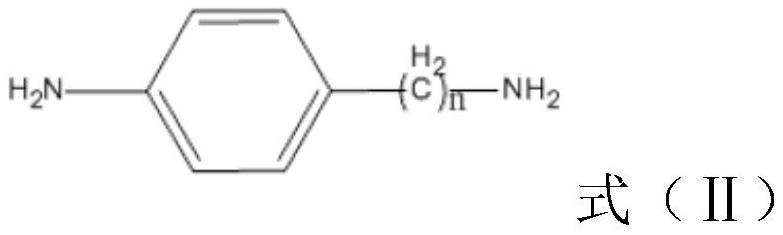

[0064] Preparation of epoxy resin curing agent A:

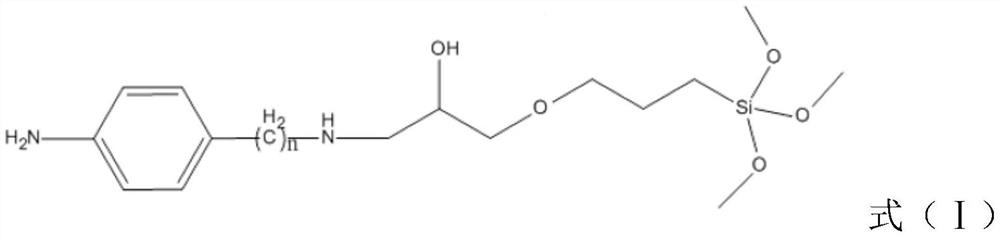

[0065] Heat and melt 122g (1mol) 4-aminobenzylamine at 40°C, add it to a three-necked flask, keep heating in an oil bath at 35°C, add 11.8g (0.05mol) KBM-403 dropwise over 0.5h, and then react at 50°C for 4h, After cooling, the epoxy resin curing agent A is obtained, and the carbon nuclear magnetic resonance spectrum analysis of the epoxy resin curing agent A shows that the chemical shift of the carbon connected to the epoxy group at 44.2ppm and 52.3ppm disappears, which proves that the KBM-403 epoxy group All ring opening reactions take place. The structure of epoxy resin curing agent A is as follows:

[0066]

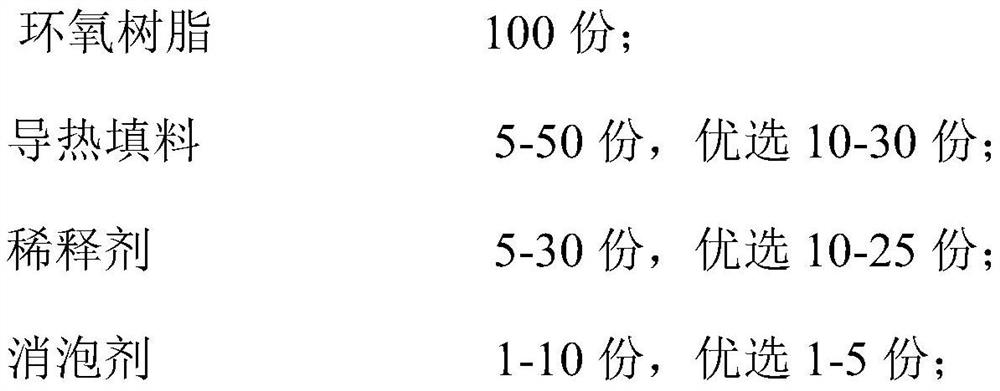

[0067] Epoxy resin composition, is prepared by the raw material of following mass parts:

[0068] A component:

[0069]

[0070] B component:

[0071] 99 parts of epoxy resin curing agent A;

[0072] 1 part of benzyl alcohol.

[0073] The preparation method steps are:

[0074] Preparation of component A:...

Embodiment 2

[0079] Preparation of epoxy resin curing agent B:

[0080] Heat and melt 136g (1mol) 4-aminophenethylamine at 35°C, add it to a three-necked flask, keep heating in an oil bath at 40°C, add 118g (0.5mol) Z-6040 dropwise over 0.3h, then react at 90°C for 1h, and cool Promptly obtain epoxy resin curing agent B, carry out carbon nuclear magnetic resonance spectrum analysis to epoxy resin curing agent B, it can be seen that the chemical shift of the carbon connected with the epoxy group at 44.2ppm and 52.3ppm disappears, which proves that the Z-6040 epoxy group is all The ring opening reaction occurs. The structure of epoxy resin curing agent B is as follows:

[0081]

[0082] Epoxy resin composition, is prepared by the raw material of following mass parts:

[0083] A component:

[0084]

[0085] B component:

[0086] 70 parts of epoxy resin curing agent B;

[0087] 30 parts of nonylphenol.

[0088] For the preparation of epoxy resin composition, the mixing and stirring...

Embodiment 3

[0091] Preparation of epoxy resin curing agent C:

[0092] Heat and melt 150g (1mol) 4-(3-aminopropyl) aniline at 50°C, add it to a three-necked flask, keep heating in an oil bath at 50°C, add 59g (0.25mol) KBM-403 dropwise over 0.1h, and then 75°C Reaction for 2.5h, cooling to obtain epoxy resin curing agent C, epoxy resin curing agent C carried out carbon nuclear magnetic resonance spectrum analysis shows that, 44.2ppm, 52.3ppm at the chemical shift of the carbon connected to the epoxy group disappears, proving that KBM- All 403 epoxy groups react with ring opening. The structure of epoxy resin curing agent C is as follows:

[0093]

[0094] Epoxy resin composition, is prepared by the raw material of following mass parts:

[0095] A component:

[0096]

[0097] B component:

[0098] 90 parts of epoxy resin curing agent C;

[0099] 10 parts of phenylethyl alcohol.

[0100] For the preparation of epoxy resin composition, the mixing and stirring temperature of compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com