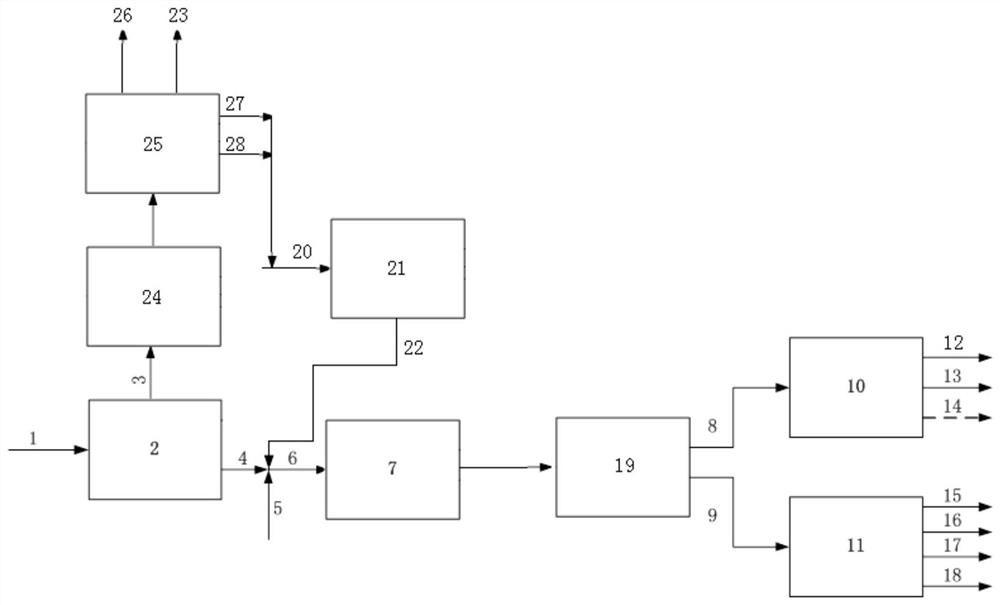

Method and system for processing heavy raw oil and aromatic-rich distillate oil

A technology for feedstock oil and distillate oil, which is applied in the system field of processing heavy feedstock oil and aromatic-rich distillate oil, can solve the problems of short operation period, affecting the economic benefits of combined technologies, and restricting promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

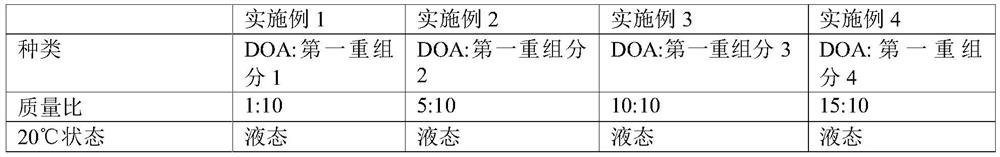

Examples

specific Embodiment approach

[0074] The conditions of the first hydrogenation unit of deasphalted oil (DAO) in the presence of hydrogen are generally as follows: the hydroprocessing technology of DAO is a fixed-bed hydroprocessing technology. Taking the relatively mature fixed-bed heavy and residual oil hydrogenation technology in the industry as an example, the reactor or reaction bed includes at least two hydrogenation catalysts, and the heavy residue hydrogenation catalyst used refers to the hydrogenation catalyst with heavy and residual oil A combined catalyst with the functions of hydrodemetallization, hydrodesulfurization, hydrodenitrogenation and hydrodecarbonization. These catalysts are generally supported by porous refractory inorganic oxides such as alumina, and oxides or sulfides of Group VIB and / or Group VIII metals such as W, Mo, Co, Ni, etc., as active components. Catalysts added with various additives such as P, Si, F, B and other elements, such as RDM, RCS series heavy and residual oil hyd...

Embodiment A

[0133] Preparation of rich ore precursor material 1: Select 2000g of RPB110 pseudoboehmite produced by Changling Branch of Sinopec Catalyst Co., Ltd., of which 1000g was treated at 550°C for 2h to obtain about 700g of alumina, and about 700g of alumina and another 1000g of pseudoboehmite Mix the boehmite thoroughly, then add 40g of scallop powder and 20g of citric acid, and add 2200g of deionized water, knead and extrude into strips, dry at 300°C for 3 hours to obtain about 1730g of carrier, add 2100mL of Mo and Ni-containing The solution is saturated impregnated, and the Mo content in the solution is expressed as MoO 3 The mass is 5.5%, and the Ni content is 1.5% by NiO mass. It is immersed for half an hour, and then treated at 180° C. for 4 hours to obtain the rich ore precursor material 1 . Properties are shown in Table 7.

[0134] Preparation of rich ore precursor material 2: Select 2000g of RPB110 pseudo-boehmite produced by Sinopec Catalyst Co., Ltd. Changling Branch, a...

Embodiment B

[0137] A vacuum residue is used as a raw material for solvent deasphalting, and the solvent used is a hydrocarbon mixture with a butane content of more than 75% by weight. At 120°C, solvent: vacuum residue = 2:1 (mass ratio) Solvent deasphalting is carried out under the conditions, the mass yield of DAO is 68%, and the mass yield of DOA is 32%.

[0138] The properties of the obtained DAO and DOA are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com