Sheep manure organic biological fertilizer and preparation method thereof

A technology of organic organisms and sheep manure, which is applied in the agricultural field, can solve the problems of long fermentation period and shortened fermentation time, and achieve the effects of low water content, lower cost, and improved resistance to diseases and insect pests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

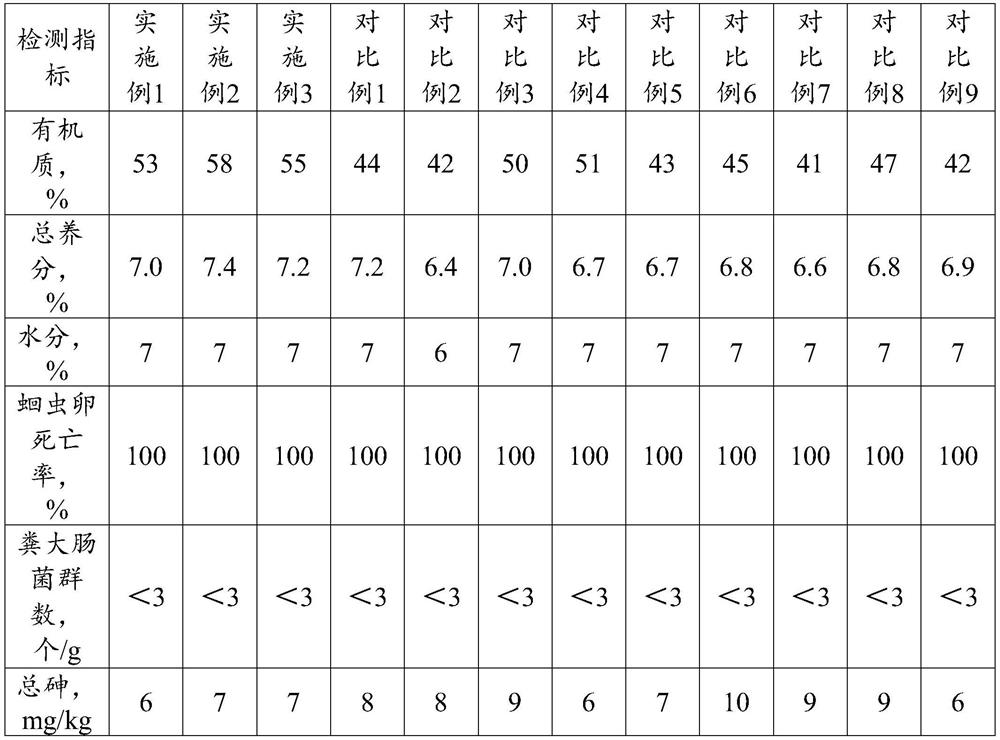

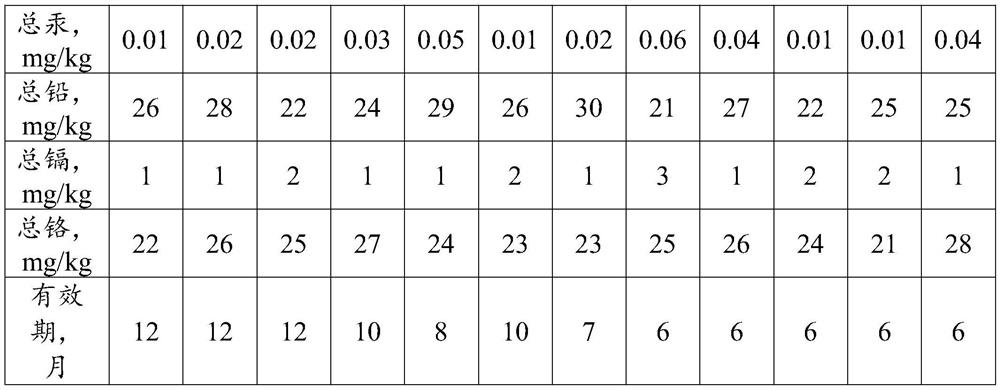

Examples

Embodiment 1

[0056] A sheep dung organic bio-fertilizer, comprising the following raw materials in parts by weight:

[0057] 60 parts of sheep manure,

[0058] Potassium fulvate 10 parts,

[0059] 10 animal carcasses,

[0060] 10 servings of meat and bone meal,

[0061] 5 copies of cigarette factory waste,

[0062] 2 parts of compound fermentation bacteria,

[0063] 2 parts of functional bacteria.

[0064] Described composite fermenting bacterium is mixed by following weight parts:

[0065] 10 parts of Bacillus subtilis,

[0066] 10 parts of Bacillus megaterium,

[0067] 10 parts of jelly-like bacillus,

[0068] 10 parts of Bacillus licheniformis,

[0069] Lactobacillus acidophilus 15 parts,

[0070] 10 parts of yeast.

[0071] The preparation method of described sheep manure organic biological fertilizer, comprises the following steps:

[0072] 1) Preparation of the composite fermentation bacteria liquid: Weighing the dry powder of the composite fermentation bacteria in propor...

Embodiment 2

[0085] A sheep dung organic bio-fertilizer, comprising the following raw materials in parts by weight:

[0086] 80 parts of sheep manure,

[0087] Potassium fulvate 120 parts,

[0088] 15 animal carcasses,

[0089] 15 servings of meat and bone meal,

[0090] 10 copies of cigarette factory waste,

[0091] 5 parts of compound fermentation bacteria,

[0092] 5 copies of functional bacteria.

[0093] Described composite fermenting bacterium is mixed by following weight parts:

[0094] 30 parts of Bacillus subtilis,

[0095] 30 parts of Bacillus megaterium,

[0096] 20 parts of jelly-like bacillus,

[0097] 20 parts of Bacillus licheniformis,

[0098] 20 parts of Lactobacillus acidophilus,

[0099] Yeast 15 parts.

[0100] The preparation method of the sheep manure organic bio-fertilizer is the same as in Example 1, the difference is that the weight ratio of the dry powder of the compound bacteria to water in the step 1) is 1:20; 0.3% of 0.3%; the addition of functional...

Embodiment 3

[0102] A sheep dung organic bio-fertilizer, comprising the following raw materials in parts by weight:

[0103] 70 parts of sheep manure,

[0104] Potassium fulvic acid 15 parts,

[0105] 15 animal carcasses,

[0106] 10 servings of meat and bone meal,

[0107] 10 copies of cigarette factory waste,

[0108] 5 parts of compound fermentation bacteria,

[0109] 5 copies of functional bacteria.

[0110] Described composite fermenting bacterium is mixed by following weight parts:

[0111] 20 parts of Bacillus subtilis,

[0112] 20 parts of Bacillus megaterium,

[0113] 15 parts of jelly-like bacillus,

[0114] 15 parts of Bacillus licheniformis,

[0115] 20 parts of Lactobacillus acidophilus,

[0116] Yeast 15 parts.

[0117] The preparation method of the sheep dung organic bio-fertilizer is the same as in Example 1, the difference is that the weight ratio of the compound bacteria dry powder to water in the step 1) is 1:20; 0.2% of weight; the addition of functional bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com