Preparation method of ethylhexylglycerin

A technology of ethylhexylglycerol and preparation steps is applied in the directions of ether preparation, ester reaction preparation of ether, ether separation/purification, etc., can solve problems such as high cost, numerous processes, complicated operation, etc., and achieve high synthesis yield and product purity , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

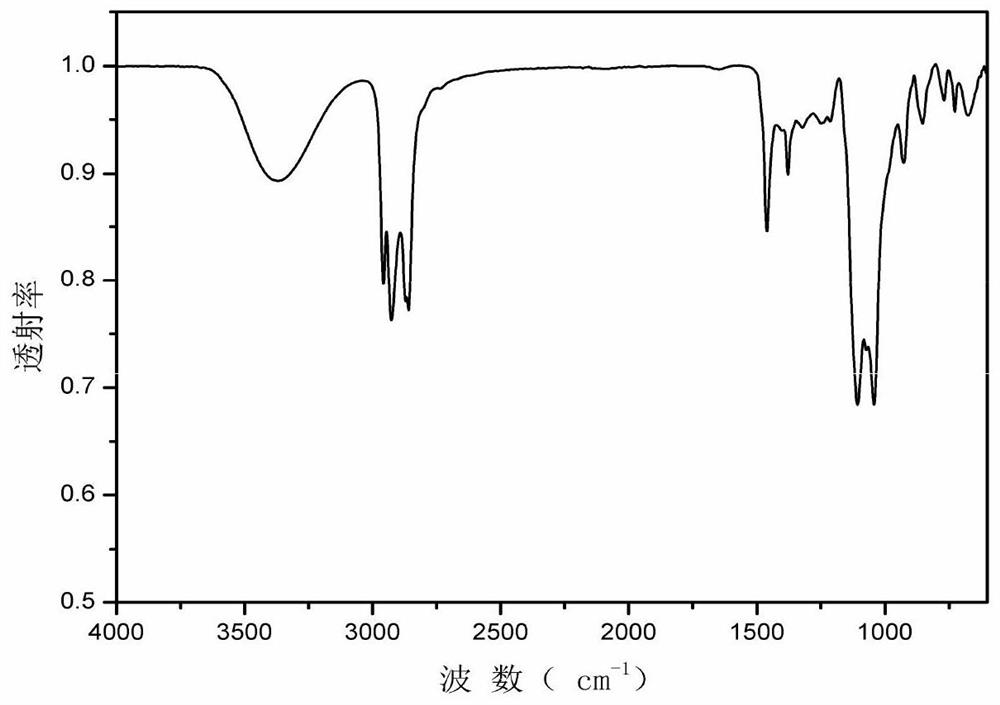

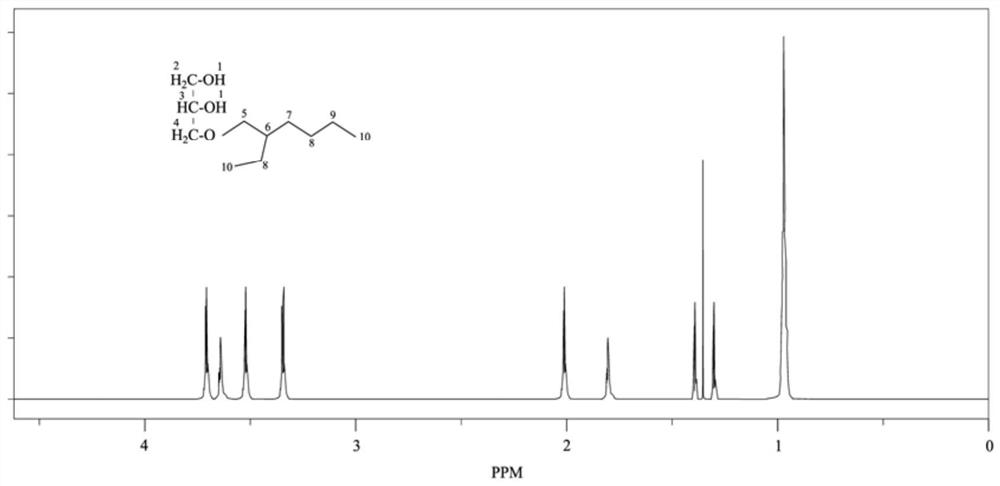

Method used

Image

Examples

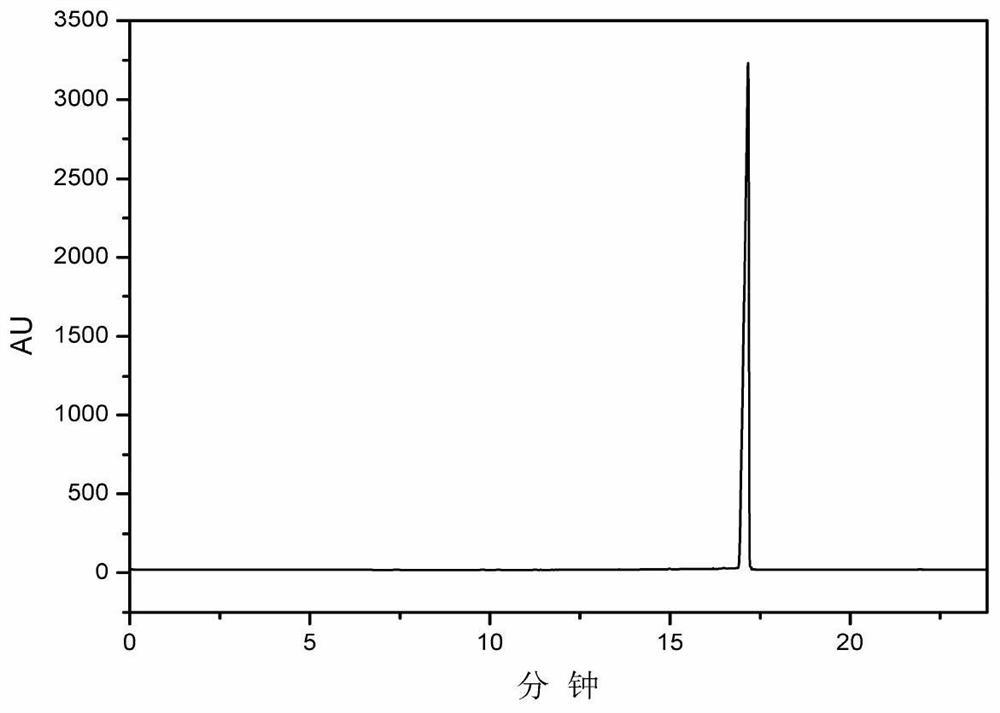

Embodiment 1

[0017] Add 65g (0.5mol) of isooctyl alcohol and 60.8g (0.5mol) of 3-chloro-1,2-propanediol into a 250ml three-necked flask equipped with a spherical condenser and a thermometer, stir, keep warm to 20°C, and add dropwise for 30 minutes Complete 112g (0.5mol) of 25% potassium hydroxide aqueous solution, heat insulation reaction for 2h, stop the reaction, adjust the pH value to neutrality (pH value=7) with hydrochloric acid solution, at 20°C, use a separatory funnel to separate the product Carry out oil-water separation, let go of the water phase, wash the organic phase twice with 100ml of water, separate the organic phase, and collect fractions at 138±3°C through molecular distillation equipment at a vacuum degree of 40-50Pa to obtain 58g of colorless transparent liquid Shape ethylhexylglycerin, through gas chromatography analysis, the purity of ethylhexylglycerin is 99.0%, and the yield is 56.9%.

Embodiment 2

[0019] Add 65g (0.5mol) of isooctyl alcohol and 60.8g (0.5mol) of 3-chloro-1,2-propanediol into a 250ml three-necked flask equipped with a spherical condenser and a thermometer, stir, heat up to 40°C, and drop it over 30 minutes After adding 110g (0.55mol) of 20% aqueous sodium hydroxide solution, keep the reaction for 3h, stop the reaction, adjust the pH value to be neutral with hydrochloric acid solution, cool to 20°C, and use a separatory funnel to separate the product from water and oil. After letting go of the water phase, wash the organic phase twice with 100ml of water, separate the organic phase, and collect fractions at 138±3°C through molecular distillation equipment at a vacuum of 40 to 50 Pa to obtain 77.9 g of ethyl alcohol as a colorless and transparent liquid. Hexylglycerin, through gas chromatography analysis, the purity of ethylhexylglycerin is 99.1%, and the yield is 76.4%.

Embodiment 3

[0021] Add 65g (0.5mol) of isooctyl alcohol and 71.8g (0.65mol) of 3-chloro-1,2-propanediol into a 250ml three-necked flask equipped with a spherical condenser and a thermometer, stir, heat up to 50°C, and drop it over 30 minutes After adding 120g (0.6mol) of 20% aqueous sodium hydroxide solution, keep the reaction for 4h, stop the reaction, adjust the pH value to be neutral with hydrochloric acid solution, cool to 20°C, and use a separatory funnel to separate the product from water and oil. After letting go of the water phase, wash the organic phase twice with 100ml of water, separate the organic phase, and collect fractions at 138±3°C through molecular distillation equipment at a vacuum of 40 to 50 Pa to obtain 88 g of ethylhexyl in the form of a colorless and transparent liquid Glycerol, through gas chromatography analysis, the purity of ethylhexylglycerin is 99.5%, and the yield is 86.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com