High-strength alkaline anionic polymer cross-linked membrane and preparation method thereof

A basic anion and polymer technology, applied in the field of materials, can solve the problem of high cost of perfluorosulfonic acid membranes, achieve excellent dimensional stability, high mechanical strength, and improve mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

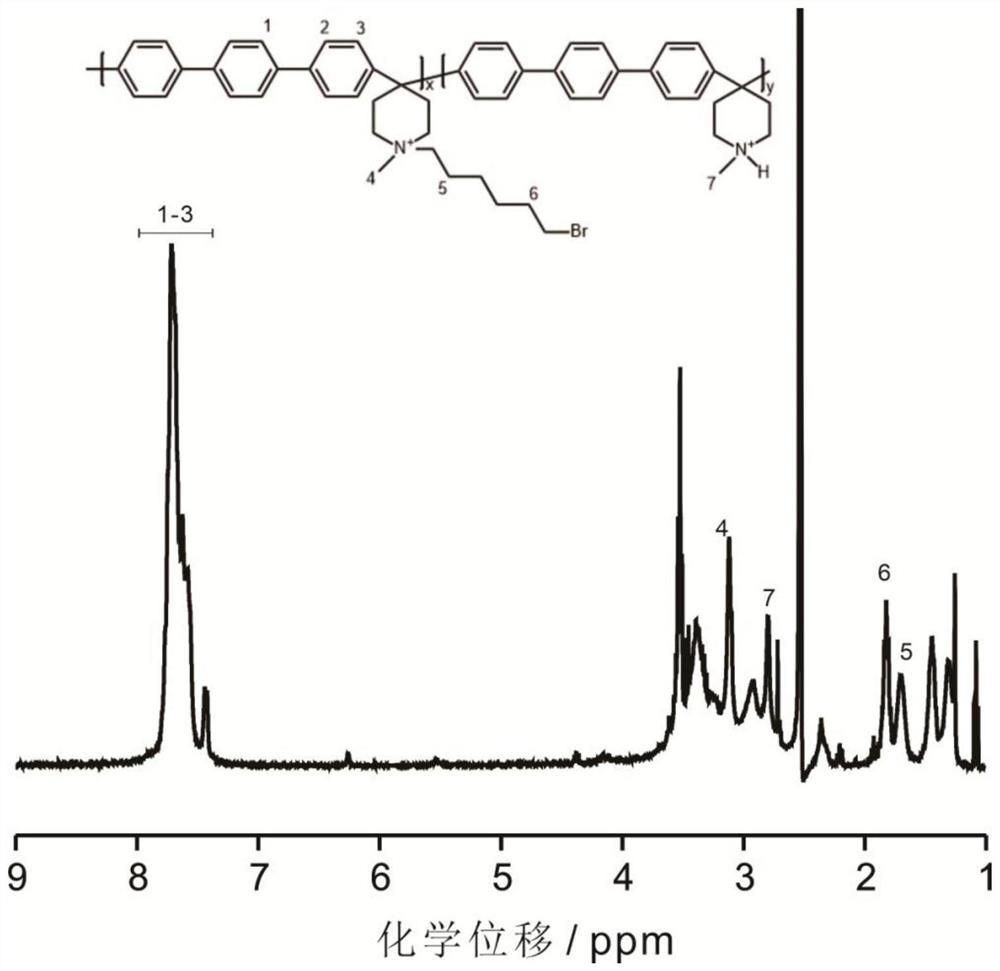

[0066] Weigh 41.0 mmol of biphenyl into a 150 mL three-necked flask, add 42.0 mmol of 1-methyl-4-piperidone, and add 8.6 mL of dichloromethane to dissolve the reactant. Under the condition of an ice-water bath, 32 mL of a mixed acid of trifluoromethanesulfonic acid and trifluoroacetic acid was added, the volume ratio of the two was 15:1, and the mixture was reacted for 3 hours. The product was precipitated in potassium carbonate solution, washed thoroughly with deionized water, and dried in an oven at 60-80°C for 24 hours. The starting polymer raw material PPP is obtained.

[0067] Weigh 10.0mmol of the above-mentioned polymer and add it into 1-methyl-2-pyrrolidone to dissolve it to prepare a polymer solution with a mass fraction of 33.3-66.7mg / mL, add 0.5 equivalent of methyl iodide and react at 40-60°C After 2-4 hours, a quaternized polymer with a reaction efficiency of 30%-50% is obtained. After the reaction was completed, it was precipitated in diethyl ether to obtain a ...

Embodiment 2

[0075] According to the method of Example 1, the initial polymer raw material PPT was synthesized by replacing biphenyl with p-terphenyl.

[0076] Weigh 10.0mmol of the above-mentioned polymer and add it to 1-methyl-2-pyrrolidone to dissolve it to prepare a polymer solution with a mass fraction of 33.3-66.7mg / mL, add 1 times the equivalent of methyl iodide and react at 40-60°C After 2-4 hours, a quaternized polymer with a reaction efficiency of 30%-50% is obtained. After the reaction was completed, it was precipitated in diethyl ether to obtain a yellow powdery solid, which was washed repeatedly with diethyl ether. The partially quaternized ionic polymer QAPPT is obtained, which is the aryl piperidine copolymer A.

[0077] Weigh 10.0mmol of the above-mentioned ionic polymer QAPPT (aryl piperidine copolymer A), add dimethyl sulfoxide to dissolve, make a polymer solution with a mass fraction of 33.3-66.7 mg / mL, add 5-7 times the equivalent of dibromo Hexane (the first alkylati...

Embodiment 3

[0083] According to the method of Example 1, the initial polymer raw material POB was synthesized by replacing biphenyl with ether ketone ether.

[0084] Weigh 10.0mmol of the above-mentioned polymer and add it into 1-methyl-2-pyrrolidone to dissolve it to form a polymer solution with a mass fraction of 33.3-66.7mg / mL, add 1.2 times the equivalent of methyl iodide and react at 40-60°C After 2-4 hours, a quaternized polymer with a reaction efficiency of 30%-50% is obtained. After the reaction was completed, it was precipitated in ether to obtain a white powdery solid, which was washed repeatedly with ether. The partially quaternized ionic polymer QAPOB is obtained, which is the aryl piperidine copolymer A.

[0085] Weigh 10.0mmol of the above-mentioned ionic polymer QAPOB, add dimethyl sulfoxide to dissolve, and make a polymer solution with a mass fraction of 33.3-66.7mg / mL, add 5-7 times the equivalent of dibromohexane at 40-60°C After reacting for 8 to 10 hours, pour the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com