Extraction method and application of fish skin collagen

A fish skin collagen and extraction method technology, which is applied in the field of fish skin collagen extraction, can solve the problems of long extraction period, failure to ensure the integrity of collagen structure, and low extraction rate, and achieve short extraction time, simple and feasible technical methods, The effect of high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

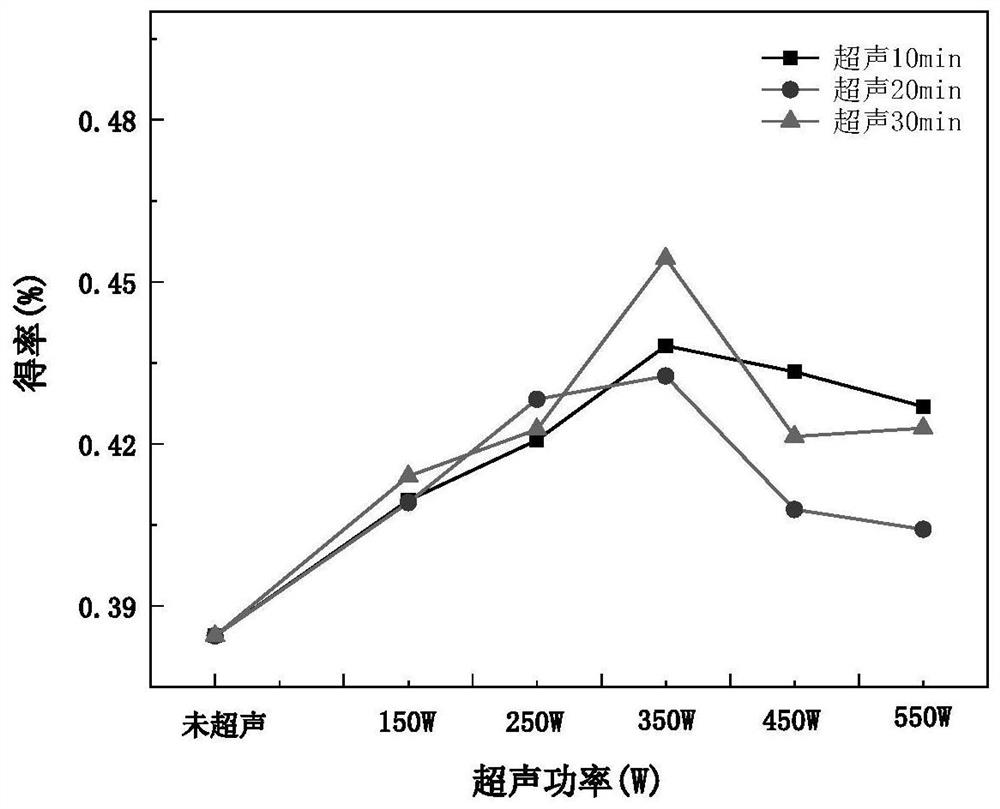

[0042] Example 1 Preparation of fish skin collagen with ultrasonic treatment power of 150W, 250W, 350W, 450W, 550W for 20min

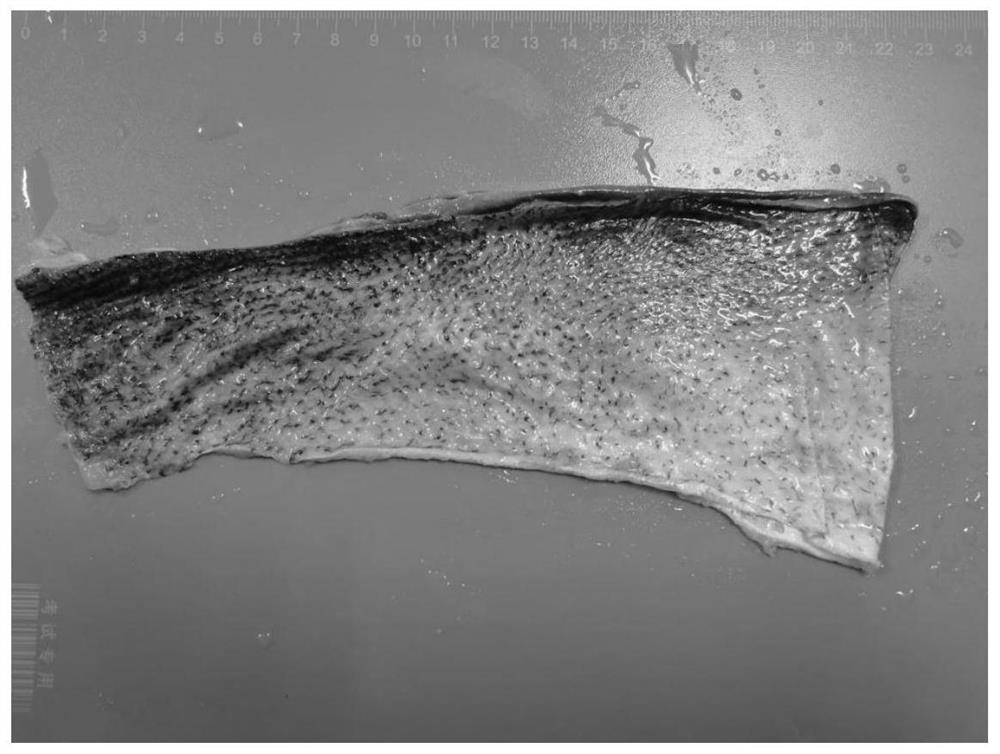

[0043] Silver carp skin raw materials such as figure 1 , the fish skin is obtained by an automatic skin peeling machine, and the remaining fish meat and black impurities are manually removed from the fish skin. Cut the fish skin into 5mm×5mm, wash it, drain it with coarse emery cloth, and weigh 163.93g.

[0044] Defat, protein removal:

[0045] (1) The volume of 0.01M NaOH is 3L, stir at 4°C for 24 hours, change the NaOH every 8 hours, rinse repeatedly with distilled water until neutral, and fully drain

[0046] (2) The volume of 10% isopropanol is 3L, stirred at 4°C for 8h, washed repeatedly with distilled water until neutral, fully drained, and weighed 365.69g.

[0047] Sonication:

[0048] Weigh 60.16g, 60.13g, 60.28, 60.35, 60.80g of degreased and protein-removed fish skin respectively, place them in 1L of 0.5M acetic acid solution and perform ...

Embodiment 2

[0056] Example 2 Preparation of fish skin collagen with ultrasonic treatment power of 150W, 250W, 350W, 450W, 550W for 30min

[0057] The fish skin is obtained by an automatic skin peeling machine, and the remaining fish meat and black impurities are manually removed from the fish skin. Cut the fish skin into 5mm×5mm, wash it, drain it with coarse emery cloth, and weigh 121.68g.

[0058] Defat, protein removal:

[0059] (1) The volume of 0.01M NaOH is 3L, stirred at 4°C for 24 hours, changing the NaOH every 8 hours, repeatedly washing with distilled water until neutral, and fully draining.

[0060] (2) The volume of 10% isopropanol is 3L, stirred at 4°C for 8h, washed repeatedly with distilled water until neutral, fully drained, and weighed 271.44g.

[0061] Sonication:

[0062] Weigh 60.04g, 60.35g, 60.07, 60.15, and 60.89g of fish skin after degreasing and removing impurities, and place them in 1L of 0.5M acetic acid solution for ultrasonic treatment; use an ultrasonic ce...

Embodiment 1、2

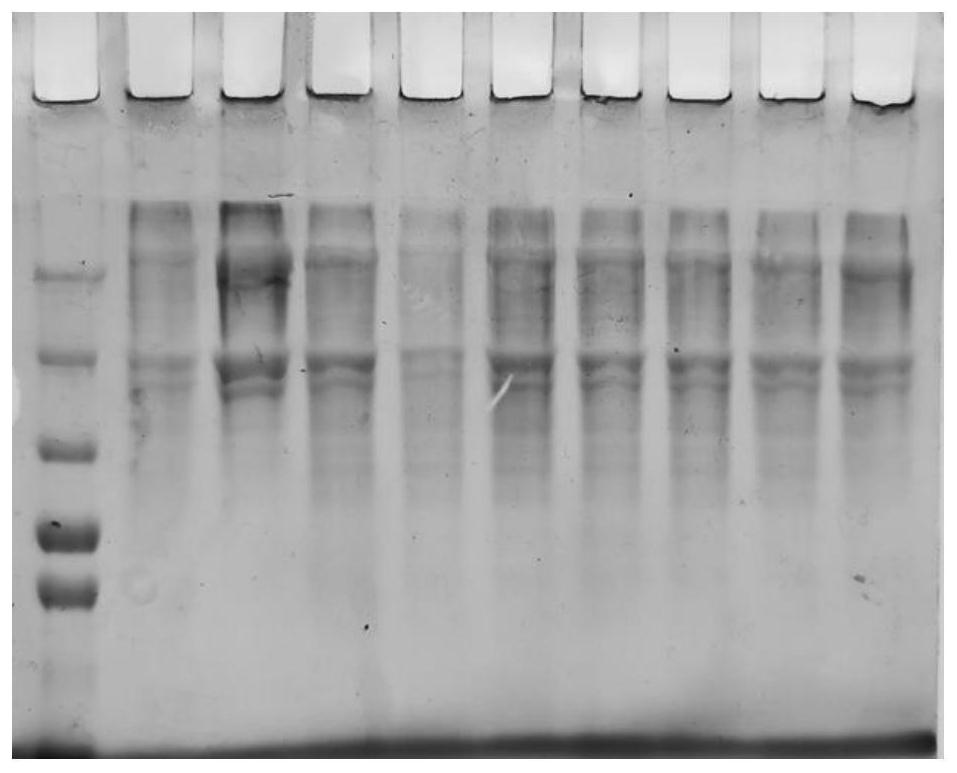

[0073] Collagen polyacrylamide gel electrophoresis (SDS-PAGE) analysis in embodiment 1,2

[0074] 7% separating gel and 4% stacking gel were selected, and the sample loading volume was 20 μL. Sample treatment: the sample is a 5mg / ml collagen solution, centrifuged at 10000r / min for 10min to remove insoluble matter, take the supernatant and mix it with sodium dodecyl sulfate (SDS) loading buffer at a volume ratio of 2:3, The collagen concentration was made 2 mg / ml. Electrophoresis conditions: initial voltage 80V, electrophoresis time 40min, then adjust the voltage to 110V. Electrophoresis time is about 90min, stop electrophoresis until the dye in the sample migrates to 2cm from the bottom. After electrophoresis, the gel was stained with Coomassie Brilliant Blue R-250 for 30 minutes, then decolorized with a mixed solution of ethanol: acetic acid: distilled water = 5:1:4 for 1 hour, and finally soaked in distilled water overnight.

[0075] The electrophoretic bands with differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com