Extracting method of citrus flavanone and preparation method of dihydrochalcone

A technology of citrus flavanones and extraction methods, which is applied in the field of extraction of citrus flavanones and preparation of dihydrochalcones, which can solve resource waste, low yield and purity of dihydrochalcones, and great environmental hazards etc., to achieve the effects of reducing mass transfer and heat transfer resistance, accelerating solvation effect, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

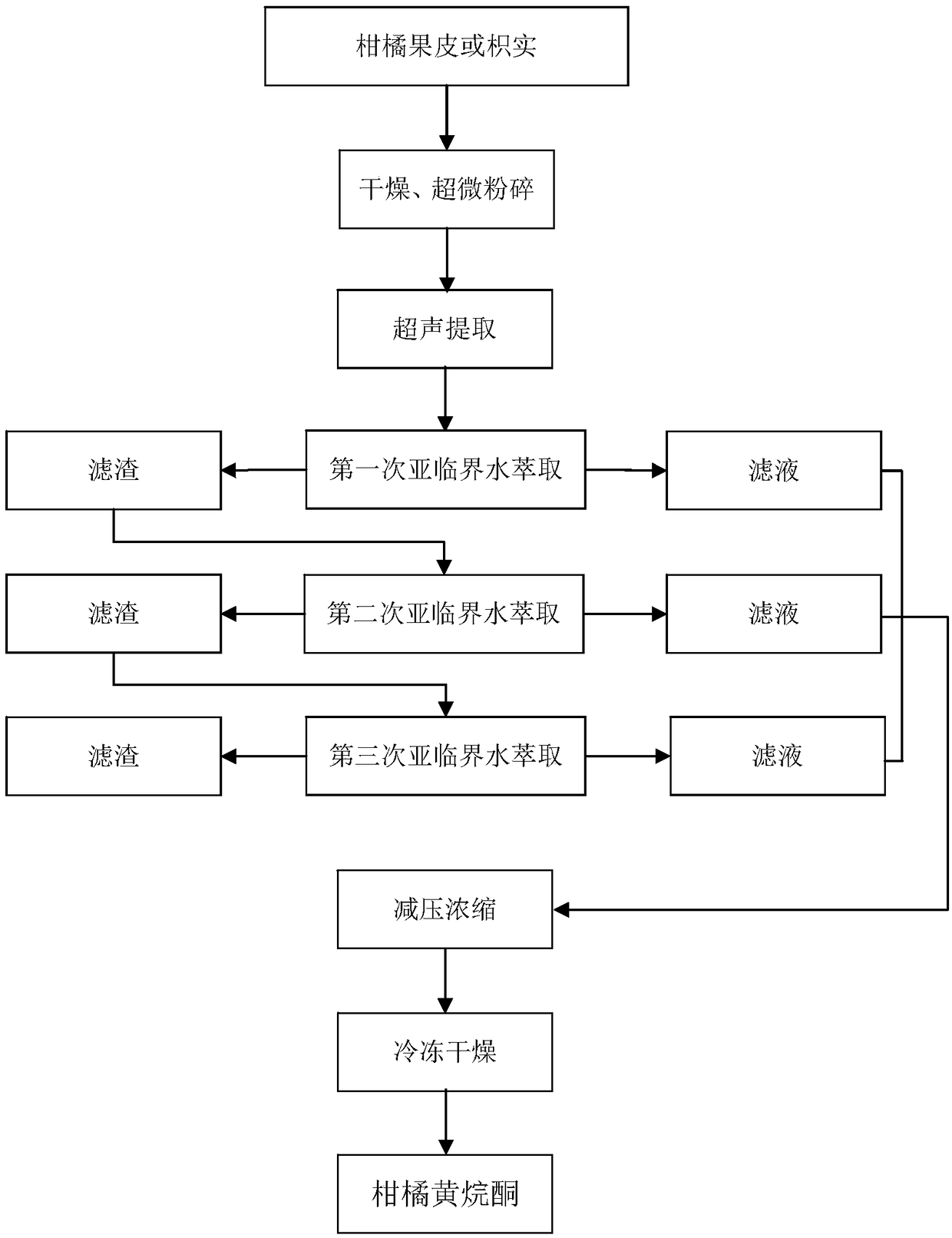

[0045] A method for extracting citrus flavanones, the process flow chart is as figure 1 shown, including the following steps:

[0046] (1) Drying and ultrafinely pulverizing the orange peel to obtain citrus peel powder, wherein the particle size of the citrus peel powder is 40 μm.

[0047] (2) According to the solid-liquid ratio of citrus peel powder and acid is 1g: 15mL, the citrus peel powder obtained in step (1) is added in the hydrochloric acid solution with a pH value of 1.8, ultrasonically extracted for 1h, filtered, and the filtered solid is Dry at 50°C to obtain citrus pomace. The resulting filtrate can be used to extract pectin.

[0048] (3) According to the mass ratio of gac and citrus peels, it is 5%, the citrus peels in the step (2) and gac are mixed uniformly, the gained mixture is packed into subcritical extraction kettle, according to the weight ratio of deoxygenated distilled water and citrus peels Add deoxygenated distilled water at a ratio of 1:8, and feed...

Embodiment 2

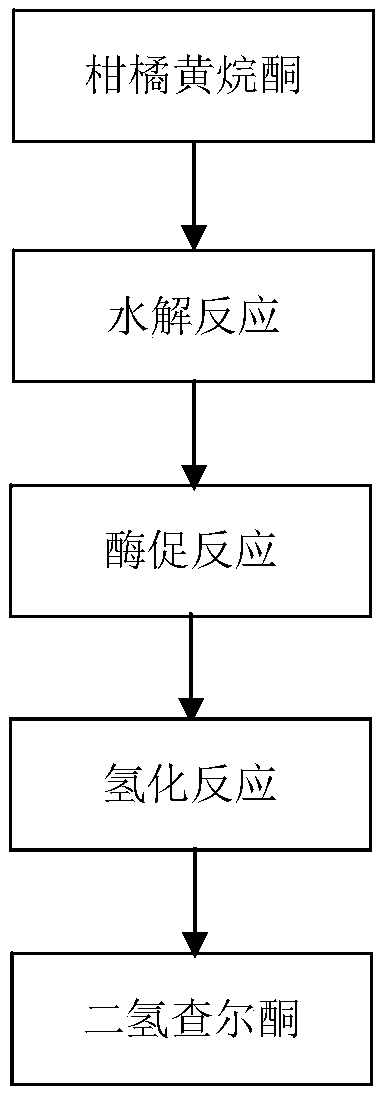

[0054] A kind of preparation method of dihydrochalcone, process flow chart is as figure 2 shown, including the following steps:

[0055] (1) Add 20 kg of the citrus flavanone powder prepared in Example 1 into 1 L of dimethyl sulfoxide (DMSO), and mix to obtain a citrus flavanone solution.

[0056] (2) According to the volume ratio of citrus flavanone solution and dilute sulfuric acid solution is 1: 50, the citrus flavanone solution obtained in step (1) is added to dilute sulfuric acid solution (the volume concentration of this dilute sulfuric acid solution is 0.25% , the temperature is 65°C), mix evenly, put the obtained mixed solution into an autoclave for hydrolysis reaction, the specific hydrolysis reaction is: carry out the first hydrolysis reaction at 140°C for 25 minutes, cool, and then continue to heat to 140°C The second hydrolysis reaction was carried out at ℃ for 25 minutes, and the hesperidin in the citrus flavanone was hydrolyzed into hesperetin and hesperetin-7-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com