Marine fuel cell hydrogen storage and supply system

A fuel cell and storage system technology, which is applied in the direction of fuel cells, fuel cell additives, power system fuel cells, etc., can solve the problem that hydrogen storage cylinders occupy a large space on ships, are unfavorable for long-term stable operation of gas cylinders, and are not suitable for ocean salt. Fog environment and other problems, to achieve the effect of increasing the space utilization of the ship, light weight, and stable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

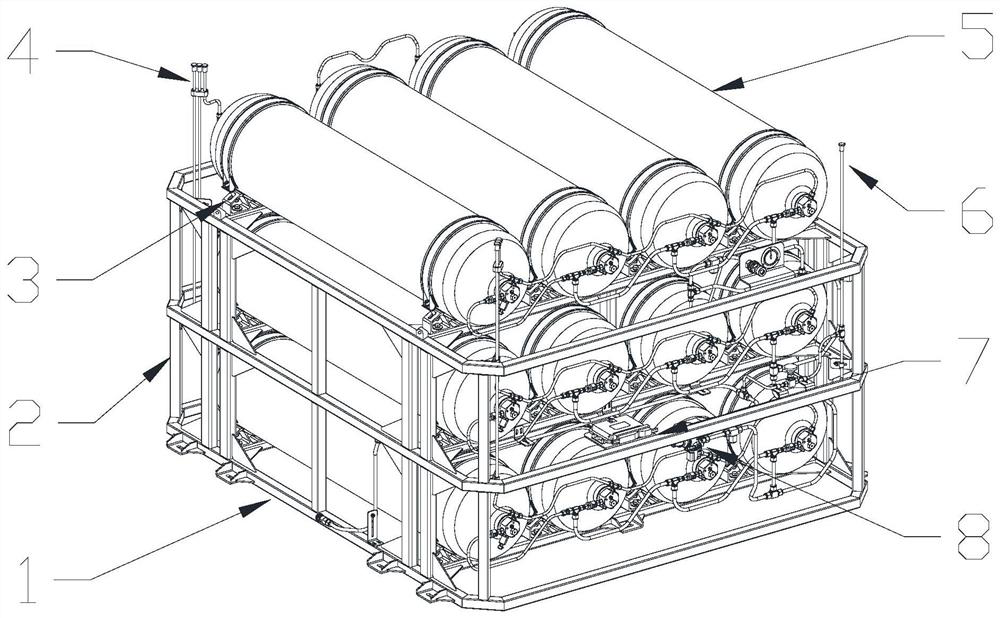

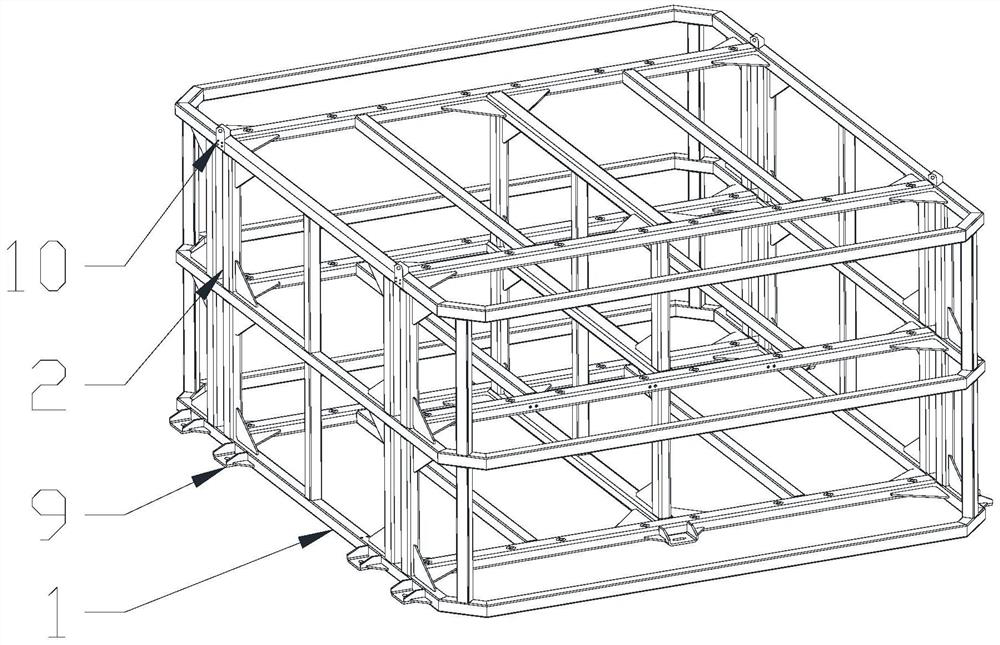

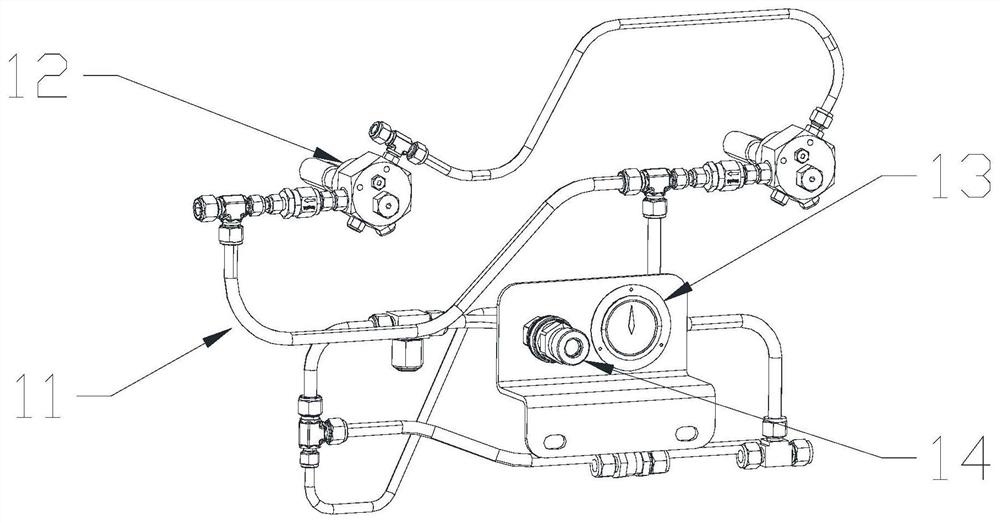

[0066] Such as Figure 1-7 As shown, a marine fuel cell hydrogen storage and supply system includes a hydrogen storage system, a hydrogen filling system 25 , a hydrogen supply system and a protective cover 23 .

[0067] The structure of the hydrogen storage system is as follows figure 1 As shown, it includes a hydrogen storage and supply system base 1, a hydrogen bottle bracket 2, a hydrogen bottle fixing device 3, a concentrated excess hydrogen gas discharge port 4, several hydrogen gas bottles 5, a hydrogen gas leakage monitoring device 7, and the like. The hydrogen filling system 25 includes a hydrogen filling port 26, a hydrogen filling pipeline 29, and the like. The hydrogen gas supply system includes a hydrogen gas control device 8 connected to the hydrogen gas bottle 5, a hydrogen supply pipeline external interface 21 connected to the hydrogen gas control device 8, a hydrogen supply pipeline 33, etc., and the hydrogen gas cylinder 5 is controlled by the hydrogen gas co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com