A zirconium steviolate catalyst used to catalyze the hydrogenation of furfural to prepare furfuryl alcohol and its preparation method

A steviol and catalyst technology, applied in the field of steviol zirconium catalyst and its preparation, can solve the problems of large amount of catalyst, harsh reaction conditions, cumbersome catalyst preparation process, etc., and achieves excellent coordination ability, simple preparation process and excellent catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take ZrCl 4 and stevia polyphenols were dissolved in DMF under the assistance of ultrasound, the mass ratio of the two was 1:1, and the stevia polyphenols solution was added dropwise to ZrCl 4 solution and keep stirring, continue to stir until the mixture is uniform, then seal it into a high-pressure reactor and keep the temperature at 120°C for 12h, naturally cool to room temperature, filter out the solid precipitate under reduced pressure, and use DMF, absolute ethanol and After washing with anhydrous ether, the obtained solid was dried in a vacuum oven at 80° C. for 12 hours. The obtained catalyst was zirconium steviolate, and its catalytic performance was tested.

Embodiment 2

[0046] According to ZrCl 4 With the mass ratio of 0.5:1 and 2:1 to stevia polyphenols, different zirconium steviolates were prepared by the preparation method in Example 1.

[0047] And carry out catalytic performance test to it:

[0048] (1) Take by weighing 1mmol furfural, 50mg catalyst zirconium steviolate and 5mL isopropanol join in the polytetrafluoroethylene container of 25mL with magnet and seal into reaction kettle;

[0049] (2) The above reaction kettle was placed in an oil bath at 120° C. and stirred for 2 hours; after the reaction, the reaction solution was centrifuged to obtain a supernatant for analysis.

[0050] After measurement, the catalytic results of different mass ratios are shown in Table 1.

[0051] Table 1 Different ZrCl 4 Catalytic result obtained by mass ratio with stevia polyphenols

[0052] mass ratio conversion rate of furfural Furfuryl alcohol yield 0.1:1 37.5% 30.4% 0.5:1 75.6% 72.0% 1:1 98.2% 95.4% 2:1 99....

Embodiment 3

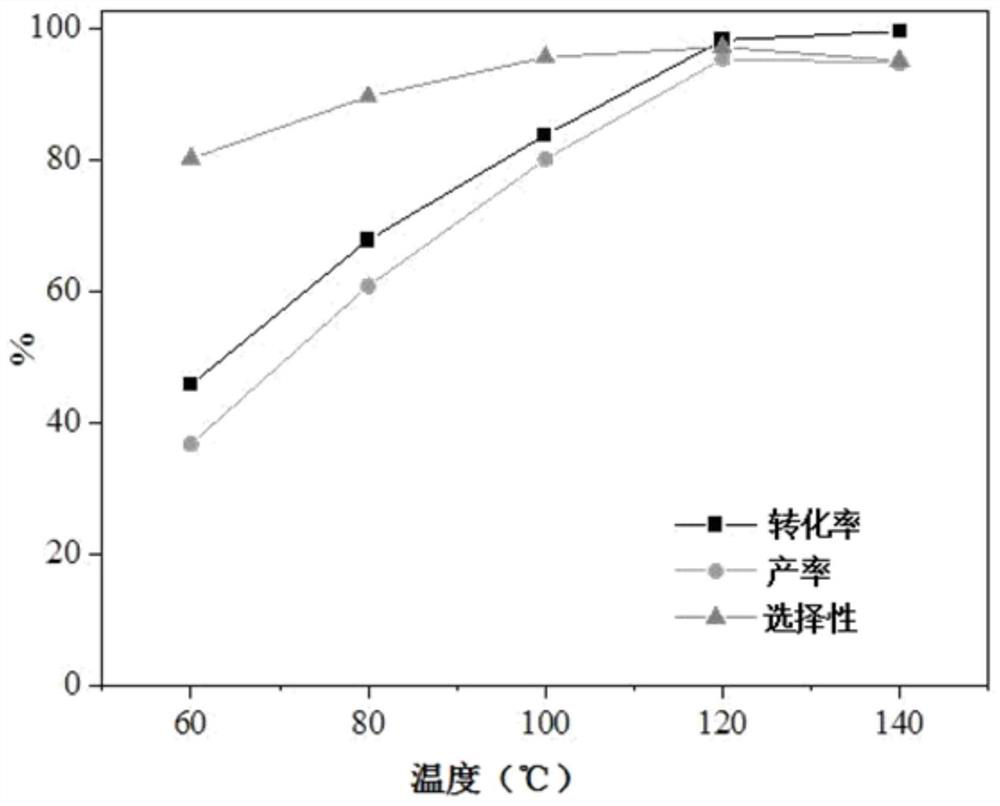

[0055] (1) Weigh 1mmol furfural, the zirconium stevia phenate catalyst prepared in 50mg embodiment 1 and 5mL isopropanol join in the 25mL reactor that has magneton, place the reactor respectively at 60, 80, 100, 120 Or stir in an oil bath at 140°C for 2 hours;

[0056] (2) Cool to room temperature after above-mentioned reaction is finished, carry out quantitative analysis to furfural and furfuryl alcohol with gas chromatograph. The result is as figure 1 and shown in Table 2.

[0057] Catalytic hydrogenation results under different reaction temperatures in table 2

[0058] temperature(℃) conversion rate of furfural Furfuryl alcohol yield 60 44.3% 37.0% 80 62.5% 56.8% 100 78.6% 73.5% 120 98.2% 95.4% 140 99.8% 91.3% 160 100% 85.0%

[0059] It can be seen that the increase in temperature is conducive to the improvement of catalytic activity, but the selectivity of furfuryl alcohol will decrease at an excessively high tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com