Method for cooperatively controlling effluent microorganisms and disinfection byproducts of sewage treatment plant

A technology for sewage treatment plants and disinfection by-products, applied in the field of collaborative control of effluent microorganisms and disinfection by-products in sewage treatment plants, can solve the problem of increasing the risk of halogenated DBPs generation, short contact reaction time of chlorine disinfectants, and adverse effects on water ecological environment, etc. It can improve the safety of effluent water quality, reduce the cost of reconstruction, and reduce the risk of generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

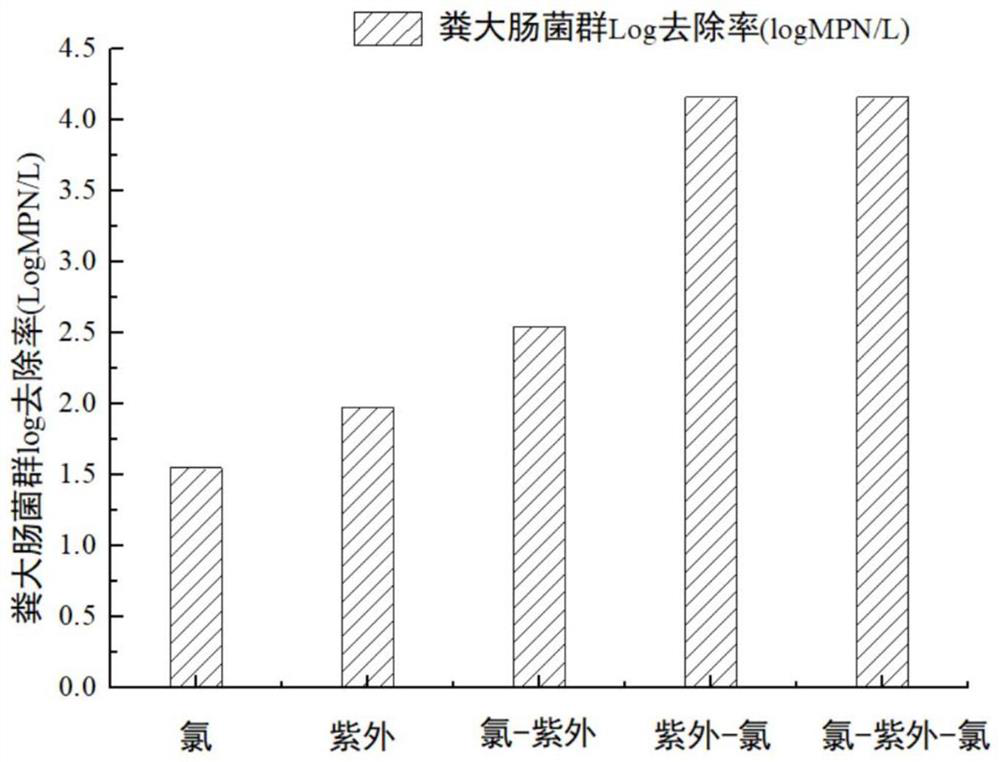

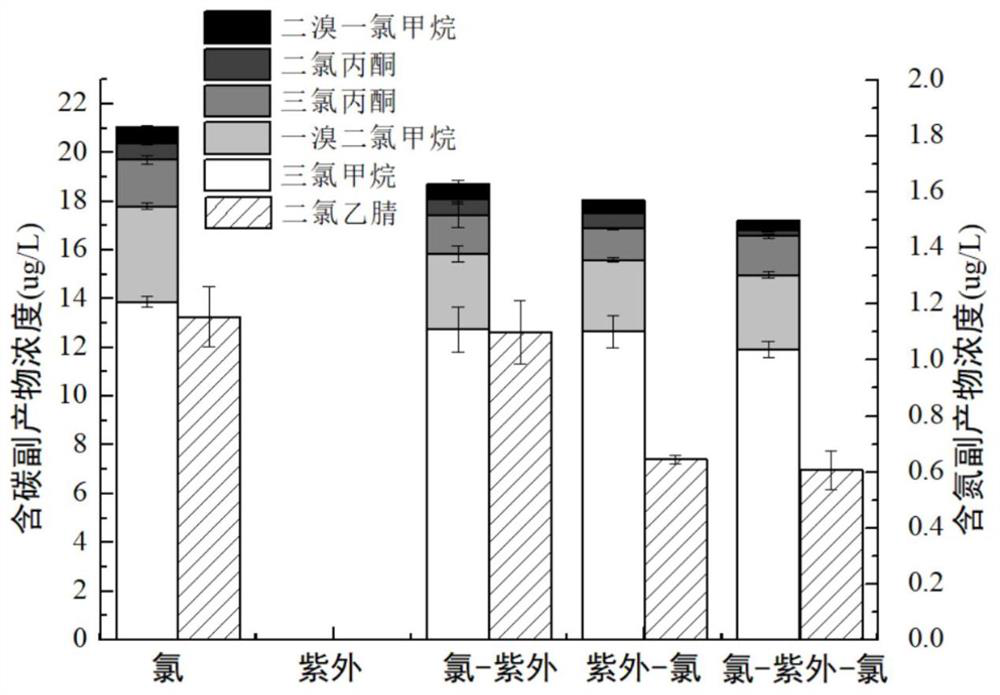

[0033] Take the effluent from the secondary sedimentation tank of a sewage plant, control the reaction temperature at 25°C, and pH 7.0, and put them in 5 kinds of separate chlorination disinfection, ultraviolet disinfection, chlorine-ultraviolet disinfection, ultraviolet-chlorine disinfection, chlorine-ultraviolet-chlorine disinfection, etc. Under the disinfection method, the specific process of each disinfection method is as follows:

[0034] (1) Alone chlorination disinfection: add 5mg / L (using Cl 2 Calculate, the same below) sodium hypochlorite disinfectant and mix, the reaction time is 10min.

[0035] (2) UV disinfection alone: place the water sample under a 254nm low-pressure UV mercury lamp for UV irradiation, and control the UV radiation dose to 50mJ / cm 2 , The reaction time is 10min.

[0036](3) Chlorine-ultraviolet sequential disinfection: add 5mg / L sodium hypochlorite disinfectant to the water sample, and after stirring for 10s, quickly adopt a low-pressure ultra...

Embodiment 2

[0042] Take the effluent from the secondary sedimentation tank of a sewage plant, control the reaction temperature at 25°C, and pH 7.0, and put them in 5 kinds of separate chlorination disinfection, ultraviolet disinfection, chlorine-ultraviolet disinfection, ultraviolet-chlorine disinfection, chlorine-ultraviolet-chlorine disinfection, etc. Under disinfection mode.

[0043] (1) Separate chlorination disinfection: add 5mg / L sodium hypochlorite disinfectant to the water sample and mix well, the reaction time is 10min.

[0044] (2) UV disinfection alone: place the water sample under a 254nm low-pressure UV mercury lamp for UV irradiation, and control the UV radiation dose to 50mJ / cm 2 , The reaction time is 10min.

[0045] (3) Chlorine-ultraviolet sequential disinfection: add 5mg / L sodium hypochlorite disinfectant to the water sample, and after stirring for 10s, quickly adopt a low-pressure ultraviolet mercury lamp with a wavelength of 254nm for ultraviolet irradiation, and c...

Embodiment 3

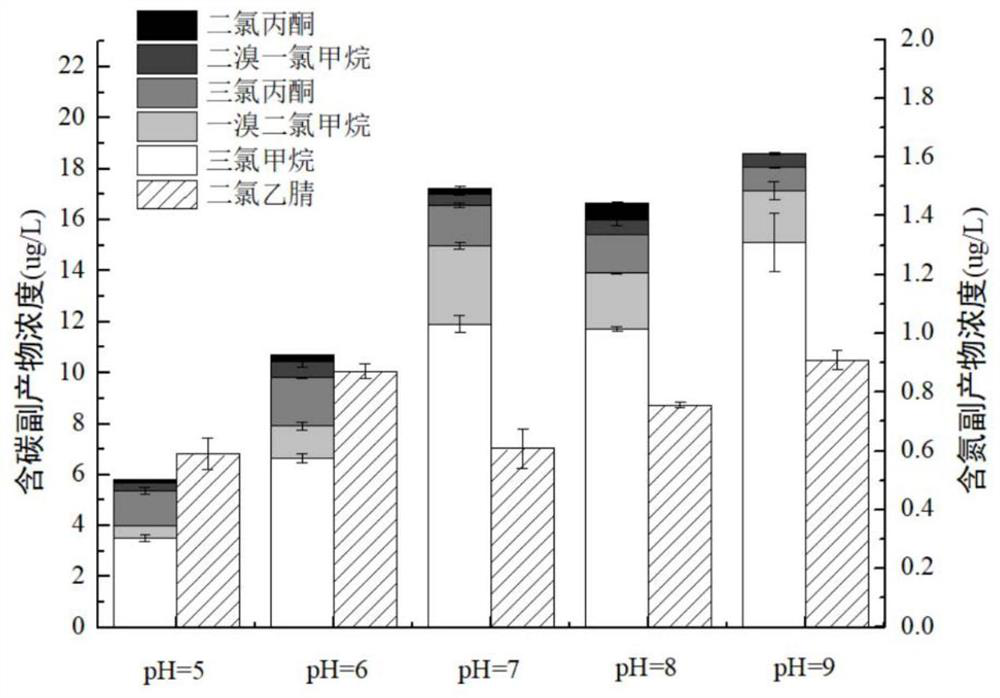

[0052] Take the effluent from the secondary sedimentation tank of a sewage plant, control the temperature at 25°C, and pH 7.0, turn on the UV radiator to preheat for half an hour, and then stabilize the UV light intensity at 50mJ / cm 2 And adjust the pH of the solution with a small volume of concentrated sulfuric acid and sodium hydroxide to 5.0, 6.0, 7.0, 8.0, 9.0 and then carry out the chlorine-ultraviolet-chlorine disinfection test. Add 2mg / L free chlorine disinfectant to the solution, stir evenly, put the solution in a petri dish and put it in the ultraviolet radiation area for ultraviolet irradiation after 10s, stir evenly, control the light intensity to 50mJ / cm 2 , control the reaction time to 5min, quickly add 3mg / L free chlorine disinfectant and stir evenly after the end, control the reaction time to 5min. After the reaction finishes, use gas chromatography to analyze the DBPs species and concentration, and the generation of DBPs in the chlorine-ultraviolet-chlorine pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com