Method for preparing energy-saving, fireproof and sound-insulating wall material from sludge solid waste and industrial slag

A technology for fire prevention, sound insulation and solid waste, which is applied in the fields of sludge treatment, oxidation treatment of sludge, chemical instruments and methods, etc., can solve problems such as affecting normal work, low utilization rate of sludge and tailings, and troublesome treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

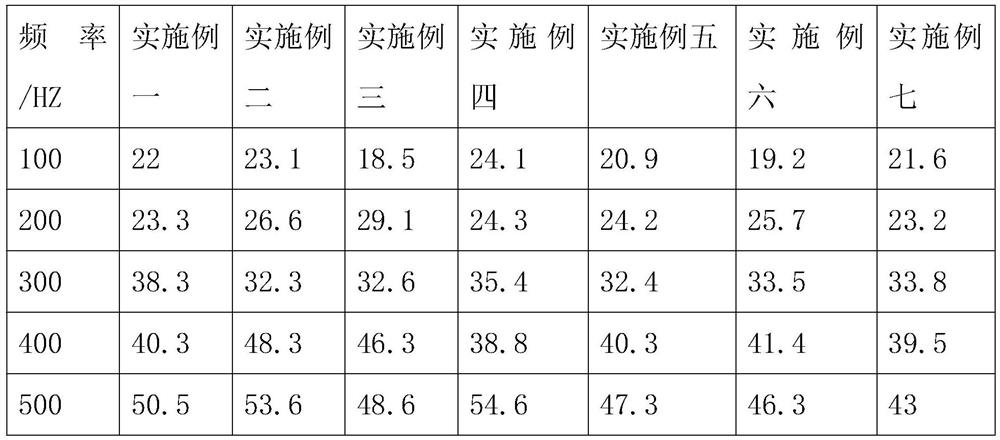

Embodiment 1

[0024] The present invention provides a technical solution: a method for preparing energy-saving, fire-proof and sound-insulating wall materials in cooperation with industrial slag from solid waste sludge. The preparation method includes the following steps:

[0025] S1: Material selection: 10 parts of sludge solid waste; 20 parts of iron ore slag; 4 parts of sodium carbonate; 25 parts of fly ash; 4 parts of silicon source material; 8 parts of organic matter; 0.1 part of modifier; 0.1 part of foam stabilizer ; Perlite 10 parts.

[0026] S2: Preparation of modified sludge solid waste: dissolve the sludge solid waste in the water in the aeration tank, and aerate the aeration tank with ozone. The aeration treatment time of the sludge modified aeration tank is 15 Minutes, let the suspended matter in the pool sink, and at the same time, use ultraviolet light to irradiate the pool to sterilize the sludge comprehensively. The sludge modified by aeration then enters the primary sedime...

Embodiment 2

[0032] The invention provides a technical scheme: the preparation method comprises the following steps:

[0033] S1: Material selection: 11 parts of sludge solid waste; 21 parts of iron ore slag; 4.5 parts of sodium carbonate; 30 parts of fly ash; 6 parts of silicon source material; 8.5 parts of organic matter; ; Perlite 11 parts.

[0034] S2: Preparation of modified sludge solid waste: dissolve the sludge solid waste in the water in the aeration tank, and aerate the aeration tank with ozone. The aeration treatment time of the sludge modified aeration tank is 20 Minutes, let the suspended matter in the pool sink, and at the same time, use ultraviolet light to irradiate the pool to sterilize the sludge comprehensively. The sludge modified by aeration then enters the primary sedimentation tank, and the modified sludge is taken out after adsorption and sedimentation for later use.

[0035] S3: Preparation of modified iron ore slag: After crushing the iron ore slag, use a screeni...

Embodiment 3

[0040] The invention provides a technical scheme: the preparation method comprises the following steps:

[0041] S1: Material selection: 11.5 parts of sludge solid waste; 21.5 parts of iron ore slag; 5 parts of sodium carbonate; 35 parts of fly ash; 8 parts of silicon source material; 9 parts of organic matter; 0.16 parts of modifier; ; Perlite 12 parts.

[0042]S2: Preparation of modified sludge solid waste: Dissolve the sludge solid waste in the water in the aeration tank, and aerate the aeration tank with ozone. The aeration treatment time of the sludge modified aeration tank is 30 Minutes, let the suspended matter in the pool sink, and at the same time, use ultraviolet light to irradiate the pool to sterilize the sludge comprehensively. The sludge modified by aeration then enters the primary sedimentation tank, and the modified sludge is taken out after adsorption and sedimentation for later use.

[0043] S3: Preparation of modified iron ore slag: After crushing the iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com