Preparation method of cationic colored copolymer microspheres

A cationic copolymer technology, applied in dyeing, textiles and papermaking, can solve the problems of different particle shapes, hard hand feeling of colored fabrics, poor dispersion stability, etc., and achieve good hand feeling, good durability and good dispersion The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

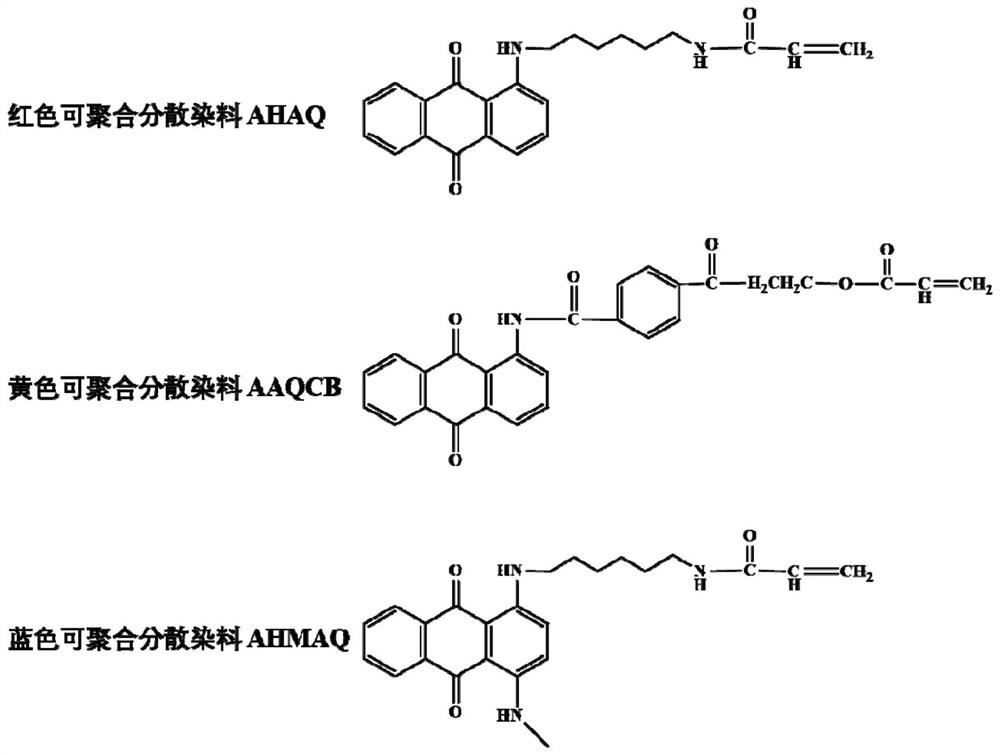

[0037] Embodiment 1: A kind of preparation method of cationic color copolymer microsphere

[0038] (1) Preparation of oil-in-water emulsion: 0.5g of dodecyltrimethylammonium chloride is dissolved in 50ml of deionized water, followed by 10g of styrene, and 0.1g of AHAQ or 0.1g of AAQCB or 0.1 g of AHMAQ and 0.5 g of 3-(methacrylamide) propyltrimethylammonium chloride were dissolved in each other and added to the above emulsifier aqueous solution, and the stirring was continued for 20 minutes.

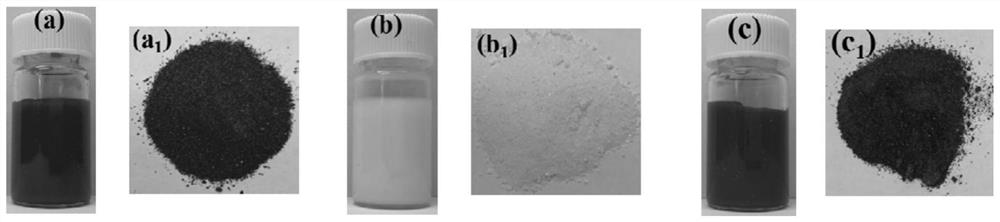

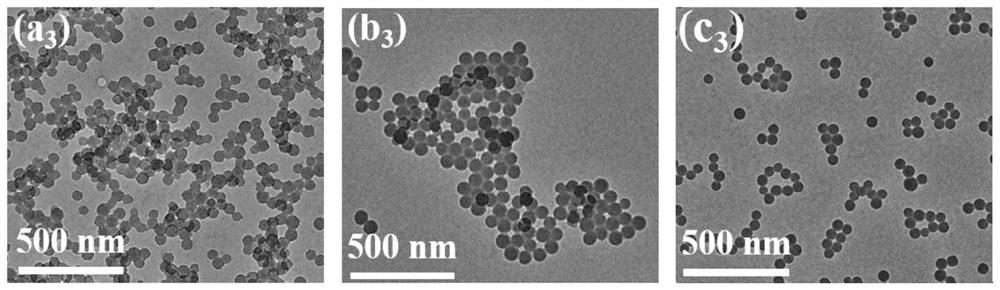

[0039] (2) Preparation of cationic copolymer microspheres: the oil-in-water emulsion prepared above was added into a three-necked flask, and the temperature was raised to 65°C. At the same time, add 0.01 g of azobisisobutylamidine hydrochloride to 5 ml of deionized water and continue to react for 10 h after the addition is completed. Finally, the prepared cationic copolymer microspheres were filtered. The properties of the prepared cationic microspheres are shown in Table 1 and Figur...

Embodiment 2

[0040] Embodiment 2: A kind of preparation method of cationic color copolymer microsphere

[0041] (1) Preparation of oil-in-water emulsion: 0.25g of cetyltrimethylammonium chloride was dissolved in 50ml of deionized water, followed by 10g of methyl methacrylate, and 0.15g of AHAQ or 0.15g AAQCB of 0.15g or AHMAQ of 0.15g, 0.5g of 3-acrylamidotrimethylammonium chloride were mutually dissolved and added to the above emulsifier aqueous solution, and continued to stir for 30 minutes.

[0042] (2) Preparation of cationic copolymer microspheres: the oil-in-water emulsion prepared above was added into a three-necked flask, and the temperature was raised to 75°C. At the same time, add 0.1 g of azobisisobutylamidine hydrochloride to 5 ml of deionized water, and continue to react for 15 hours after the addition is completed. Finally, the prepared cationic copolymer microspheres were filtered. The properties of the prepared cationic microspheres are shown in Table 1 and Figure 2-5 s...

Embodiment 3

[0043] Embodiment 3: A kind of preparation method of cationic color copolymer microsphere

[0044] (1) Preparation of oil-in-water emulsion: the octadecyldimethylbenzyl ammonium chloride of 0.25g is dissolved in the deionized water of 50ml, then the methyl methacrylate of 10g, and the AHAQ of 0.15g or 0.15g of AAQCB or 0.15g of AHMAQ and 1g of 2-methacryloyloxyethyltrimethylammonium chloride were dissolved in each other and added to the above emulsifier aqueous solution, and continued to stir for 40 minutes.

[0045] (2) Preparation of cationic copolymer microspheres: the oil-in-water emulsion prepared above was added into a three-necked flask, and the temperature was raised to 80°C. At the same time, add 0.1 g of azobisisobutylamidine hydrochloride to 5 ml of deionized water, and continue to react for 24 hours after the addition is completed. Finally, the prepared cationic copolymer microspheres were filtered. The properties of the prepared cationic microspheres are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com