Polyamide-imide resin, optical film, and flexible display device

A polyamide-imide resin, polyamide-imide technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as easy cracking and utilization of front panel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0231]The solvent used for the preparation of the varnish is not particularly limited as long as it can dissolve the above-mentioned resin. Examples of the solvent include amide-based solvents such as DMAc and DMF; lactone-based solvents such as GBL and γ-valerolactone; sulfur-containing solvents such as dimethyl sulfone, dimethyl sulfoxide, and sulfolane; Carbonate-based solvents such as ethyl ester and propylene carbonate; and combinations thereof. Among these, an amide-based solvent or a lactone-based solvent is preferable. These solvents may be used alone or in combination of two or more. In addition, water, an alcohol-based solvent, a ketone-based solvent, an acyclic ester-based solvent, an ether-based solvent, and the like may be contained in the varnish. The solid content concentration of the varnish is preferably 1 to 25% by mass, more preferably 5 to 20% by mass, and further preferably 5 to 15% by mass.

[0232] In the coating step, the varnish is coated on the sup...

Embodiment

[0294] Hereinafter, the present invention will be described in more detail using examples. Unless otherwise specified, "%" and "part" in an example mean mass % and a mass part. First, the evaluation method will be described.

[0295] A / int B ) Determination>

[0296] Based on HSQC-NMR (int A / int B ) is obtained in the following manner.

[0297] (1) Preparation method of test sample

[0298] The polyamideimide resin was dissolved in deuterated dimethyl sulfoxide (DMSO-d 6 ), a 2% by mass solution was prepared, and this was used as a measurement solution.

[0299] (2) Measurement conditions

[0300] Measuring device: 600 MHz NMR device AVANCE600 manufactured by Bruker

[0301] Sample temperature: 303K

[0302] Determination method: HSQC

[0303] Chemical shift reference: DMSO (2.49ppm for proton, 40.44ppm for carbon)

[0304] (3) Analysis method

[0305] In the obtained HSQC-NMR spectrum, by integration, the volume of the peak present in the region A where the che...

Embodiment 2

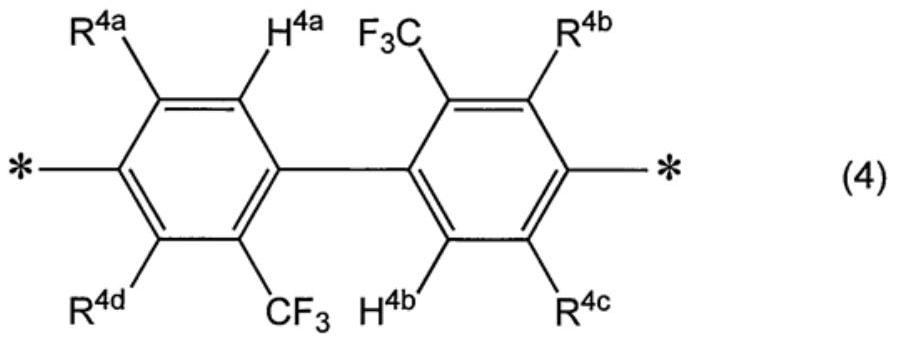

[0356] Under nitrogen atmosphere, to 3m equipped with stirring blade 3 23.66 kg of TFMB and DMAc with a moisture content adjusted to 300 ppm were added to the reaction vessel so that the solid content concentration of TFMB in the reaction mixture was 5.54 mass %, and TFMB was dissolved in DMAc while stirring at room temperature. . Next, 6FDA was added so that it might become 30.21 mol% with respect to TFMB in the reaction container, and it stirred at 25 degreeC for 16 hours. Then, TPC and OBBC were added so that it might become 60.42 mol % and 10.07 mol % with respect to TFMB, respectively, and it stirred for 60 minutes. Next, 4-picoline and acetic anhydride were added so as to be 35.25 mol % and 105.74 mol %, respectively, with respect to TFMB, and after stirring for 30 minutes, the average temperature of the wall and bottom of the reaction mixture was adjusted to The temperature was raised from 25°C to 50°C over 30 minutes, from 50°C to 60°C over 10 minutes, from 60°C to 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com