Solid-state battery with low interface impedance, and preparation method thereof

A solid-state battery and interface impedance technology, applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve difficult problems such as electrolyte interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

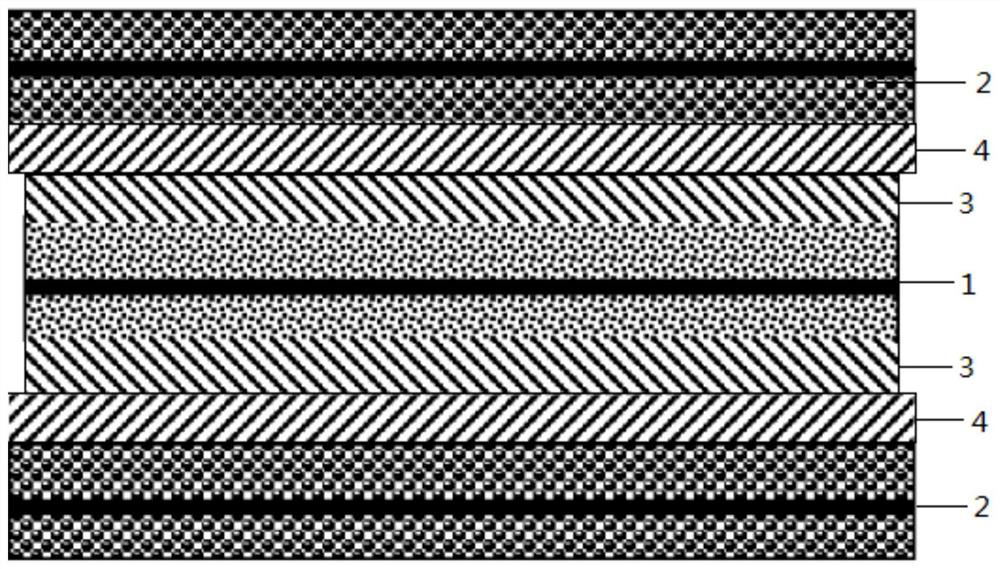

[0033] A solid-state battery with low interfacial impedance, such as figure 1 As shown, the preparation is as follows:

[0034] (1) Add 10g of lithium iron phosphate, 0.16g of carbon black, 0.27g of PVDF, 0.16g of lithium lanthanum zirconate, and 0.005g of lithium hexafluorophosphate into an appropriate amount of NMP and mix evenly, and apply it on the surface of aluminum foil and roll it to obtain a composite positive electrode sheet 1 (single-sided Area density: 173g / m 2 ).

[0035] (2) Mix 10g of graphite, 0.05g of carbon black, 0.16g of CMC, 2.63g of SBR (solid content 4%), 0.16g of lithium lanthanum zirconate and 0.05g of lithium hexafluorophosphate into deionized water and coat them on the surface of copper foil Obtain composite negative electrode sheet 2 (single surface density is: 79g / m2) after roll pressing 2 ).

[0036] (3) Add 5g of PEO, 0.08g of lithium lanthanum zirconate and 0.03g of lithium hexafluorophosphate into an appropriate amount of tetrahydrofuran an...

Embodiment 2

[0039] A solid-state battery with low interfacial impedance, such as figure 1 As shown, the preparation is as follows:

[0040] (1) Add 10g of lithium iron phosphate, 0.16g of carbon black, 0.27g of PVDF, 0.16g of lithium lanthanum zirconate, and 0.005g of lithium hexafluorophosphate into an appropriate amount of NMP and mix evenly, and apply it on the surface of aluminum foil and roll it to obtain a composite positive electrode sheet 1 (single-sided Area density: 173g / m 2 ).

[0041] (2) Mix 10g of graphite, 0.05g of carbon black, 0.16g of CMC, 2.63g of SBR (solid content 4%), 0.16g of lithium lanthanum zirconate and 0.05g of lithium hexafluorophosphate into deionized water and coat them on the surface of copper foil Obtain composite negative electrode sheet 2 (single surface density is: 79g / m2) after roll pressing 2 ).

[0042](3) Add 5 g of PEO, 0.08 g of lithium zirconate lanthanum and 0.03 g of lithium hexafluorophosphate into an appropriate amount of tetrahydrofuran,...

Embodiment 3

[0045] A solid-state battery with low interfacial impedance, such as figure 1 As shown, the preparation is as follows:

[0046] (1) Add 10g of lithium iron phosphate, 0.16g of carbon black, 0.27g of PVDF, 0.16g of lithium lanthanum zirconate, and 0.005g of lithium hexafluorophosphate into an appropriate amount of NMP and mix evenly, and apply it on the surface of aluminum foil and roll it to obtain a composite positive electrode sheet 1 (single-sided Area density: 173g / m 2 ).

[0047] (2) Add 10g of graphite, 0.05g of carbon black, 0.16g of CMC, 2.63g of SBR (solid content 4%), 0.16g of lithium lanthanum zirconate and 0.05g of lithium hexafluorophosphate into an appropriate amount of deionized water and mix evenly. Obtain composite negative electrode sheet 2 after pressing (single surface density is: 79g / m 2 ).

[0048] (3) 5g of PEO, 0.08g of lithium lanthanum zirconate and 0.03g of lithium hexafluorophosphate were added to an appropriate amount of tetrahydrofuran and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com