High-temperature energy storage hybrid polyetherimide dielectric film and preparation method and application thereof

A technology of polyetherimide dielectric and polyether amic acid, which is applied in the field of high-temperature energy storage hybrid polyetherimide dielectric film and its preparation, and can solve the problems of limited application and lack of energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] S2. Preparation of anhydrous protic solvent containing a small amount of water: use a pipette to uniformly disperse a small amount of water into 2 mL of anhydrous aprotic solvent to obtain an anhydrous protic solvent containing a small amount of water.

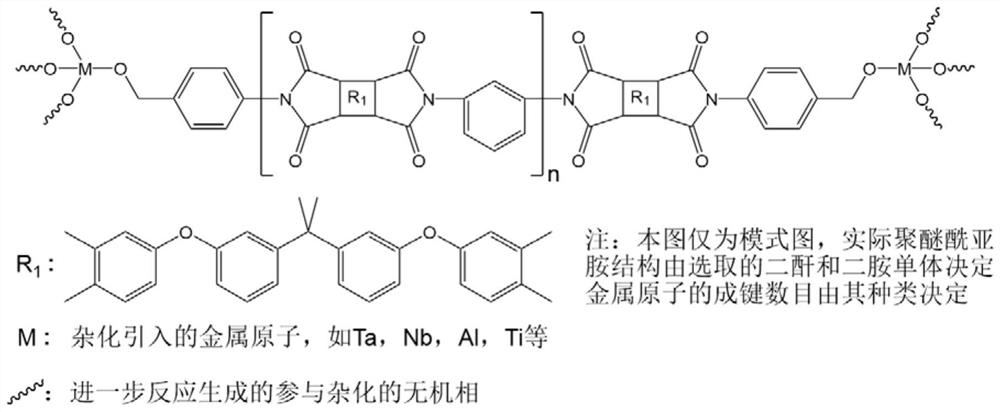

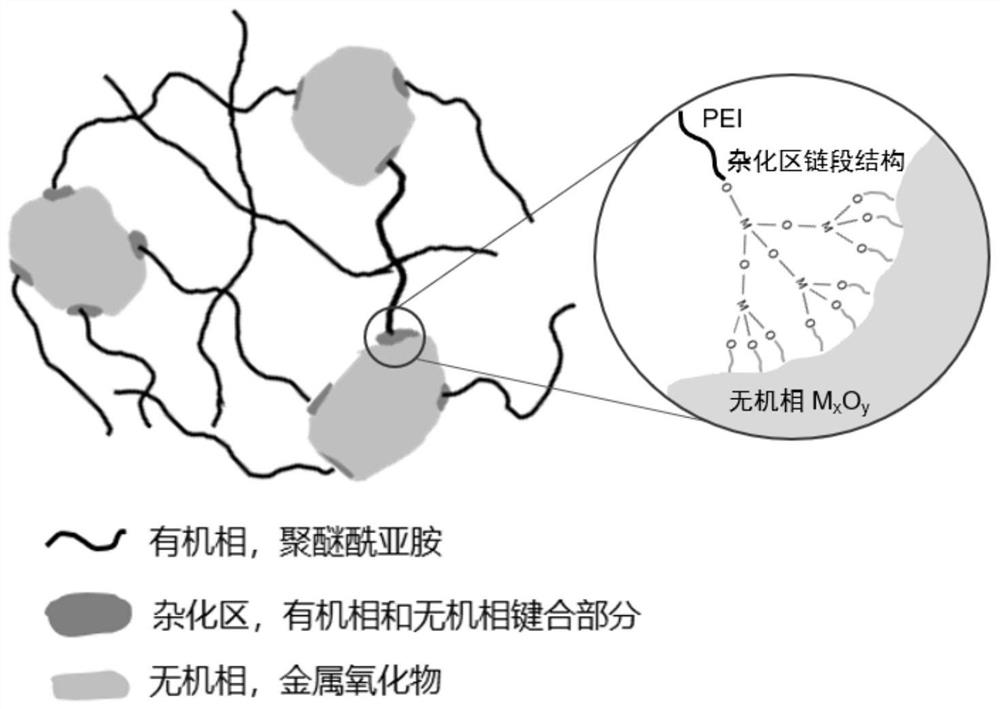

[0040] S3. Preparation of hybrid polyetheramic acid slurry: Add the anhydrous protic solvent containing a small amount of water obtained in step S2 into the polyetheramic acid solution obtained in step S1, and stir for 10 minutes to make it uniformly dispersed. Use a pipette to take the metal alkoxide (if the alkoxide is solid, measure it) and disperse it evenly in the anhydrous aprotic solvent while stirring. Subsequently, the metal alkoxide solution was added to the polyetheramic acid solution, and stirred at room temperature for 1 hour to obtain a hybrid polyetheramic acid slurry.

[0041] S3. Preparation of hybrid polyetherimide film: drop hybrid polyetheramic acid slurry on a clean glass plate, coat it to a certain...

Embodiment 1

[0048] Composition and ratio of raw materials:

[0049]

[0050]

[0051] Preparation:

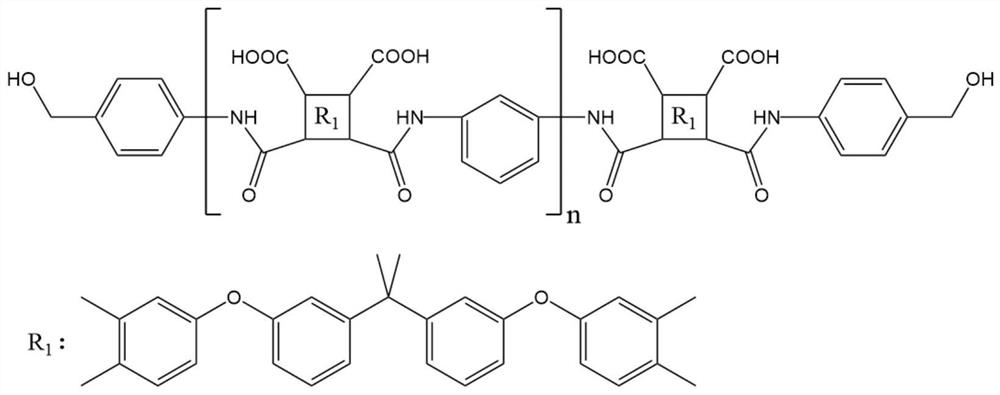

[0052] Preparation of hydroxyl-functionalized polyetheramic acid solution: 87.4 mg of m-phenylenediamine and 1.0 mg of p-aminobenzyl alcohol were weighed and dissolved in 7 mL of anhydrous N-methylpyrrolidone. After the diamine was completely dissolved by stirring, 426.9 mg of bisphenol A diether dianhydride (BPADA) was added three times while stirring, and the dianhydride was added every 5 minutes to ensure that the previously added dianhydride was completely dissolved. When the dianhydride was added for the last time, the viscosity of the solution increased significantly, and the reaction ended. The solution was kept stirring at 25° C. for 1 hour to obtain a polyether amic acid solution with a solid content of 6.7%.

[0053] Preparation of hybrid alumina / polyetheramic acid slurry: Use a pipette to take 10.5 μL of water and evenly disperse it into 2 mL of anhydrous N-methylpyrroli...

Embodiment 2

[0059] Composition and ratio of raw materials:

[0060]

[0061] Preparation:

[0062] Preparation of hydroxyl-functionalized polyetheramic acid solution: 87.4 mg of m-phenylenediamine and 1.0 mg of p-aminobenzyl alcohol were weighed and dissolved in 7 mL of anhydrous N-methylpyrrolidone. After the diamine was completely dissolved by stirring, 426.9 mg of bisphenol A diether dianhydride (BPADA) was added three times while stirring, and the dianhydride was added every 5 minutes to ensure that the previously added dianhydride was completely dissolved. When the dianhydride was added for the last time, the viscosity of the solution increased significantly, and the reaction ended. The solution was kept stirring at 25° C. for 1 hour to obtain a polyether amic acid solution with a solid content of 6.7%.

[0063] Preparation of hybrid tantalum oxide / polyetheramic acid slurry: Use a pipette to take 15.8 μL of water and evenly disperse it into 2 mL of anhydrous N-methylpyrrolidone....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy storage density | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com