Composite packaging film as well as preparation method and application thereof

A composite packaging film and packaging film technology, applied in the field of packaging materials, can solve problems such as high energy consumption, narrow use range, and inability to recycle, and achieve high application value and increase the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

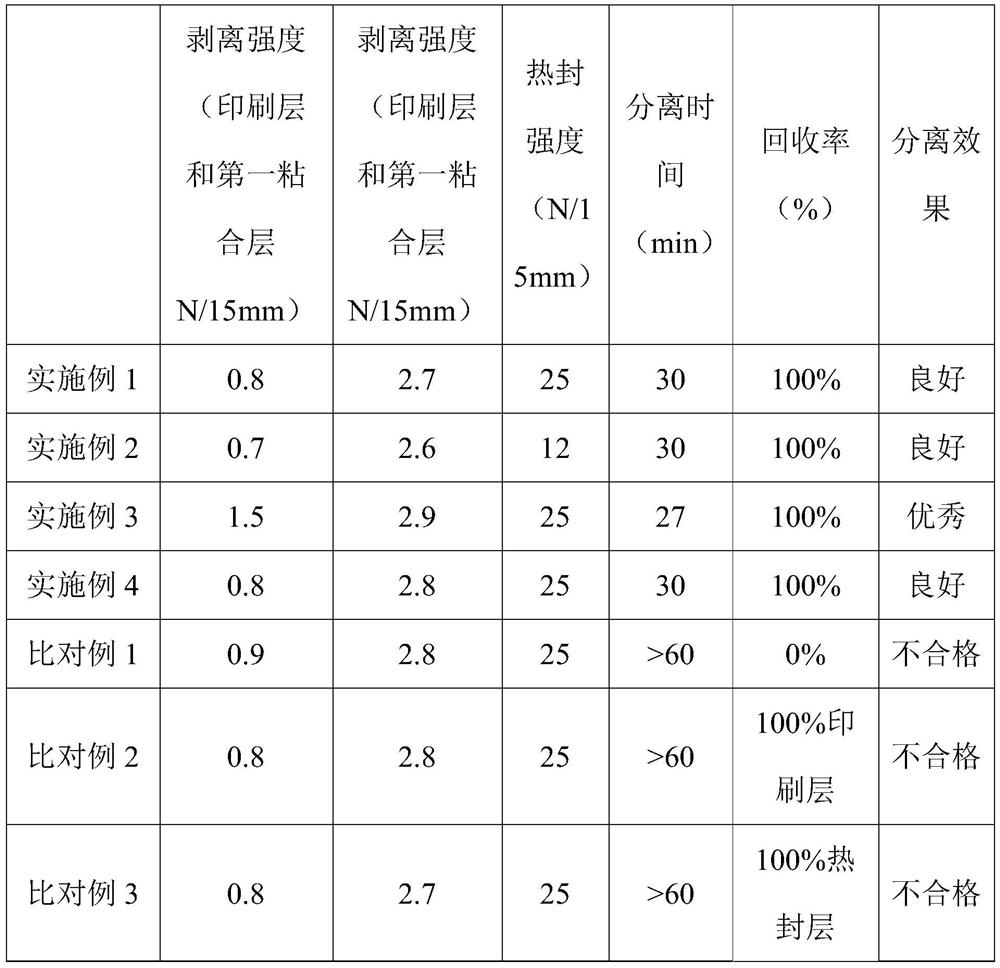

Embodiment 1

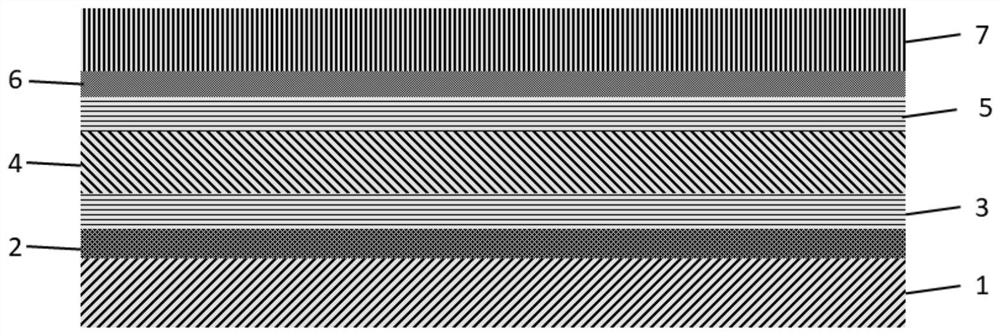

[0041] A composite packaging film, the schematic diagram of the cross-sectional structure is as follows figure 1 As shown, wherein, including a printing layer 1, a first adhesive layer 2, a first separation layer 3, a barrier layer 4, a second separation layer 5, a second adhesive layer 6 and a heat-sealing layer 7 arranged in sequence;

[0042] Printing layer 1 has a grammage of 60g / m 2 coated paper (Stora Enso, Lumiflex); the first adhesive layer 2 is a polyethylene layer with a thickness of 15 μm (Shanghai Zijiang Color Printing Packaging Co., Ltd); the first separation layer 3 is a polyvinyl alcohol coating with a thickness of 1 μm ( Nissyn, EXCEVAL); the barrier layer 4 is an aluminum foil (Xiashun, AA8079 / O) with a thickness of 15 μm; the second separation layer 5 is a polyvinyl alcohol coating (Nissei, EXCEVAL) with a thickness of 1 μm; the second adhesive Layer 6 is a polyethylene layer with a thickness of 15 μm (Shanghai Zijiang Color Printing Packaging Co., Ltd.); h...

Embodiment 2

[0049] A kind of composite packaging film, the section structure is identical with embodiment 1;

[0050] The weight of the printing layer is 40g / m 2 Medical paper (Sappi, 40gsm); the first adhesive layer is an ethylene-vinyl acetate copolymer layer (Shanghai Zijiang Color Printing Packaging Co., Ltd.) with a thickness of 10 μm; the first separation layer is a polyvinyl alcohol coating with a thickness of 0.5 μm layer (Nissan, EXCEVAL); the barrier layer is a metallized polyester film (Tongda, FW) with a thickness of 12 μm; the second separation layer is a polyvinyl alcohol coating (Nissan, EXCEVAL) with a thickness of 0.5 μm; the second The adhesive layer is an ethylene-vinyl acetate copolymer layer (Shanghai Zijiang Color Printing Packaging Co., Ltd.) with a thickness of 10 μm; the heat-sealing layer is a polyethylene layer with a thickness of 25 μm;

[0051] Its preparation method is identical with embodiment 1.

Embodiment 3

[0053] A kind of composite packaging film, its sectional structure is identical with embodiment 1;

[0054] Printing layer 1 has a grammage of 80g / m 2 Kraft paper (Hehe, Chisong); the first adhesive layer is a polyurethane adhesive coating (NOVACOTE, SF2930) with a thickness of 5 μm; the first separation layer is a polyvinyl alcohol coating (Nissei, EXCEVAL) with a thickness of 3 μm ); the barrier layer is a metallized polyolefin film (Jindal, MM488) with a thickness of 18 μm; the second separation layer is a polyvinyl alcohol coating (Nissei, EXCEVAL) with a thickness of 3 μm; the second adhesive layer is a thickness of 5 μm Polyurethane adhesive coating (NOVACOTE, SF735A / CA478); the heat-sealing layer is a polyethylene film with a thickness of 150 μm (Shanghai Zijiang Color Printing Packaging Co., Ltd.);

[0055] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com