Microbial fertilizer containing biological enzyme amino acid and preparation method thereof

A technology of microbial fertilizer and amino acid is applied in the field of microbial fertilizer containing biological enzyme amino acid and its preparation, which can solve the problems of poor crop quality improvement effect, low nutrient composition, low survival rate, etc., so as to save fertilization labor and reduce fertilization cost. , the effect of high fertilizer utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

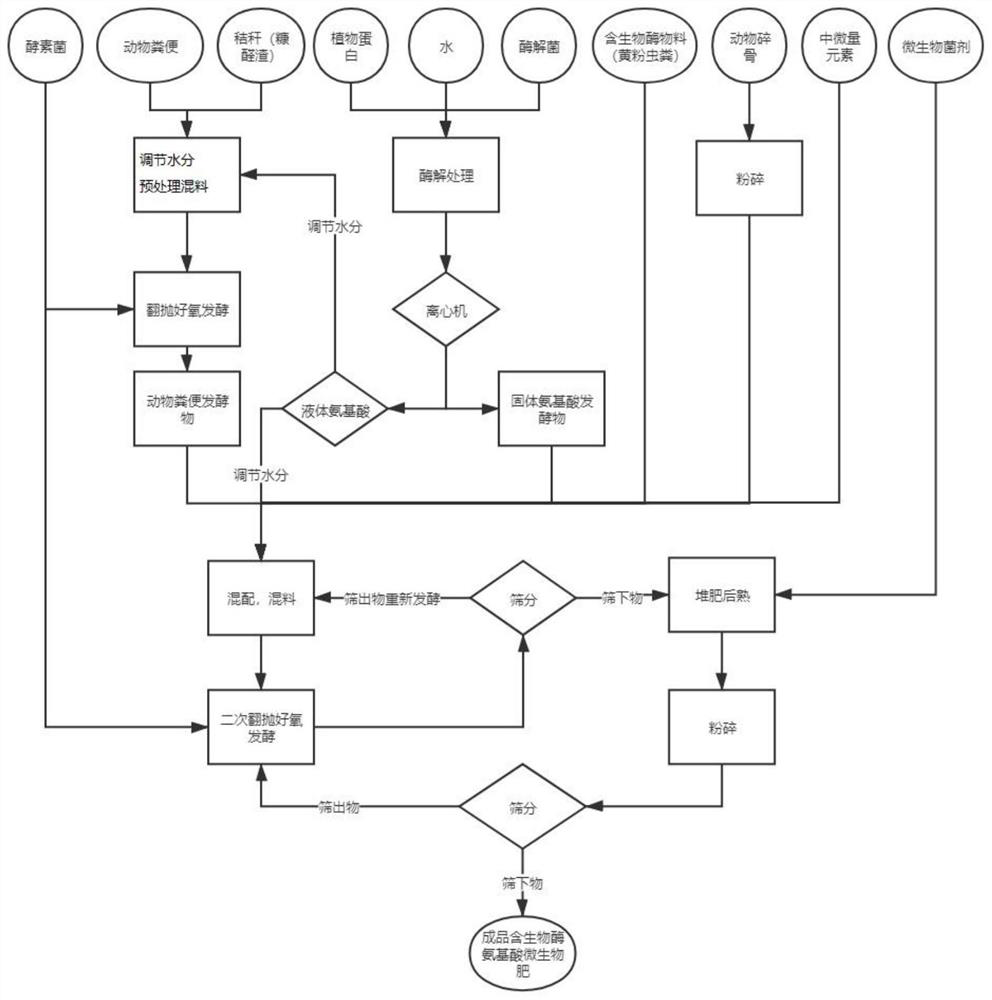

Method used

Image

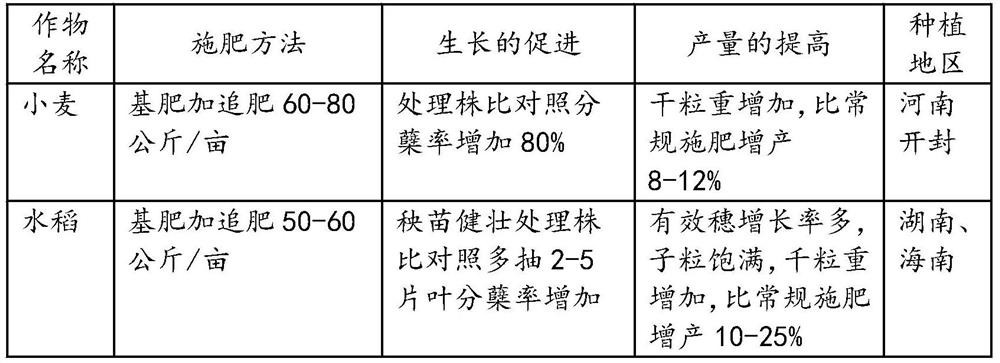

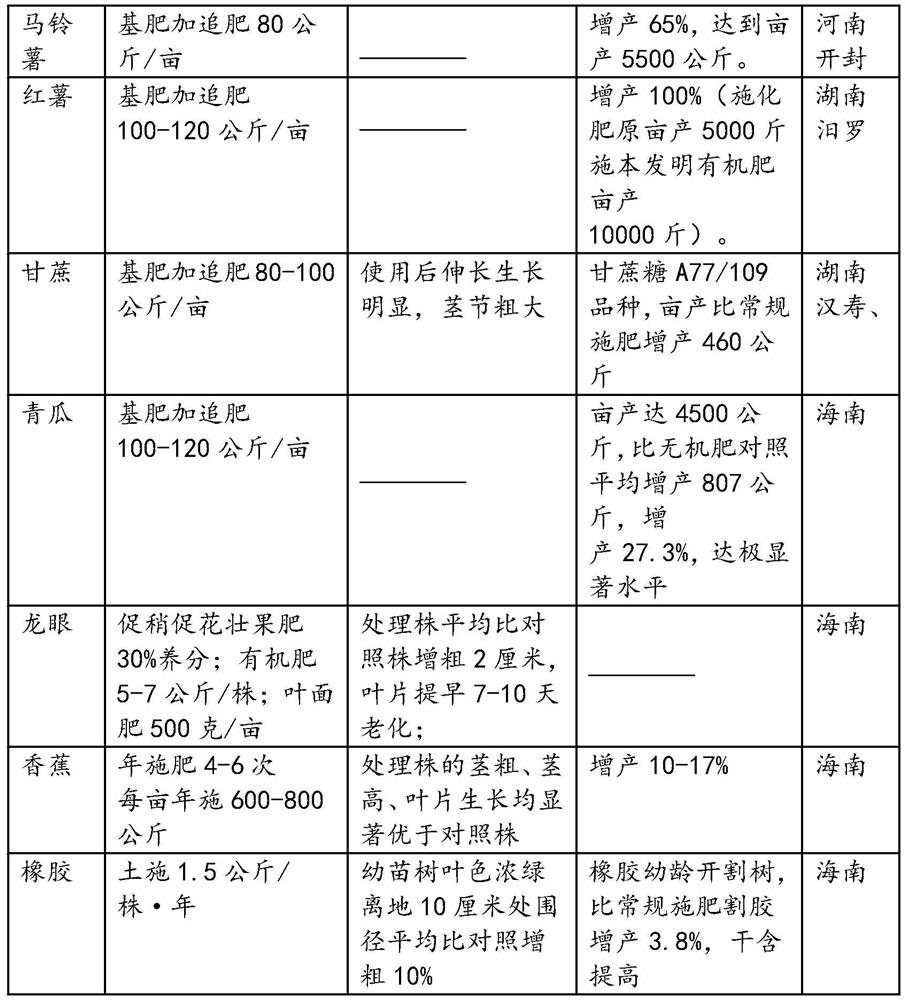

Examples

Embodiment 1

[0044] Raw materials: 30 parts of sheep manure, 5 parts of furfural residue, 30 parts of soybean meal, 30 parts of Tenebrio molitor manure, 2 parts of broken animal bones, 0.5 parts of medium and trace elements, 1 part of enzyme bacteria, 0.5 parts of enzymatic bacteria, jelly-like spores 1 part of bacillus and 45 parts of water.

[0045] making process:

[0046] (1) Add soybean meal, water and enzymatic bacteria into the reaction kettle, ferment at 50-60°C for 20 days, stir 4 times a day, 10 minutes each time, after the fermentation, centrifuge at 2000rpm for 20min to separate the liquid amino acid solution and Solid amino acid ferment.

[0047] (2) Crushing the broken animal bones, and passing through a 100-mesh sieve to obtain animal bone powder.

[0048] (3) Mix sheep manure and furfural slag to obtain mixture A, adjust the water content of mixture A to 55% with the liquid amino acid solution obtained in step (1), then add 0.5 parts of enzyme bacteria, and pile it up to ...

Embodiment 2

[0053] Raw materials: 20 parts of sheep manure, 20 parts of chicken manure, 15 parts of furfural dregs, 30 parts of soybean meal, 10 parts of soybean, 25 parts of Tenebrio molitor manure, 15 parts of vermicompost, 5 parts of broken animal bones, 3 parts of medium and trace elements, enzyme bacteria 5 parts, 3 parts of enzymatic bacteria, 3 parts of jelly-like Paenibacillus, 3 parts of Bacillus subtilis and 60 parts of water.

[0054] making process:

[0055] (1) Add soybean meal, soybean, water and enzymatic bacteria into the reaction kettle, ferment at 50-60°C for 15 days, stir 4 times a day, 10 minutes each time, after fermentation, centrifuge at 1500rpm for 30min to obtain liquid amino acid Solution and solid amino acid ferments.

[0056] (2) Crushing the broken animal bones, and passing through a 60-mesh sieve to obtain animal bone powder.

[0057] (3) Mix sheep manure, chicken manure and furfural slag to obtain mixture A, adjust the water content of mixture A to 55% wit...

Embodiment 3

[0062] Raw materials: 5 parts of sheep dung, 5 parts of cow dung, 1 part of furfural residue, 10 parts of soybean meal, 10 parts of Tenebrio molitor manure, 0.1 part of animal bone, 0.1 part of medium and trace elements, 1 part of enzyme bacteria, 0.3 parts of enzymatic bacteria, 1 part of jelly-like Paenibacillus and 15 parts of water.

[0063] making process:

[0064] (1) Add soybean meal, water and enzymatic bacteria into the reaction kettle, ferment at 50-60°C for 25 days, stir 4 times a day, 10 minutes each time, after fermentation, centrifuge at 2000rpm for 20min to separate the liquid amino acid solution and Solid amino acid ferment.

[0065] (2) Crushing the broken animal bones, and passing through a 100-mesh sieve to obtain animal bone powder.

[0066] (3) Mix sheep manure, cow manure and furfural slag to obtain mixture A, adjust the water content of mixture A to 55% with the liquid amino acid solution obtained in step (1), add 0.5 parts of enzyme bacteria, and pile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com