Surface texturing solar glass self-cleaning anti-reflection structure and method

A solar glass and surface texture technology, applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of low processing efficiency, coating or coating peeling off, etc., to reduce reflected energy and enhance transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention aims at the problems that the solar cell panels and solar water heaters are easy to accumulate pollutants and reduce the efficiency of solar energy use when they are used outdoors for a long time, and optimizes the solar glass surface microstructure.

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but this should not be used as a limitation to the protection scope of the present application.

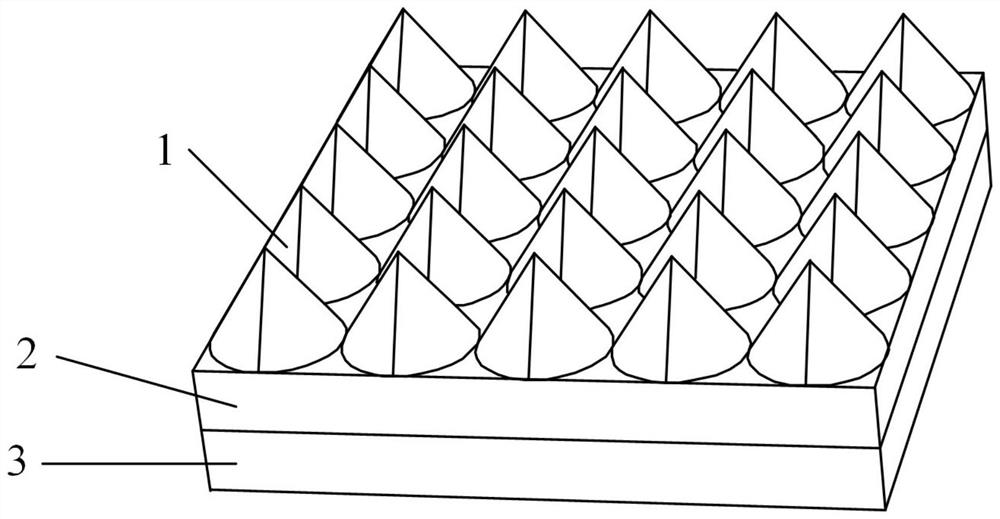

[0030] As a possible implementation, such as figure 1 As shown, on the upper surface of the solar glass 2, a conical sub-wavelength biomimetic microstructure 1 is prepared by using ultraviolet picosecond laser, femtosecond laser processing, micro-milling processing and combined processing methods;

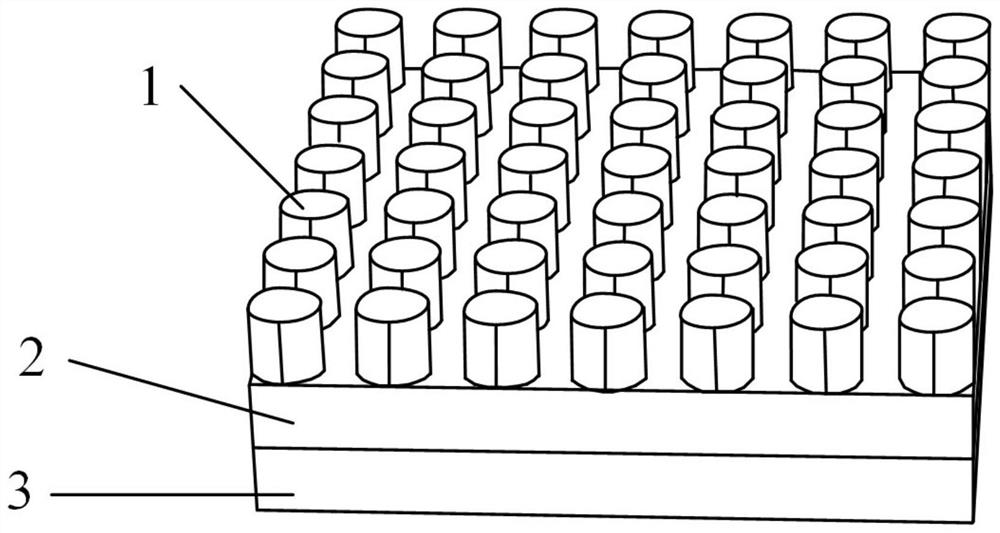

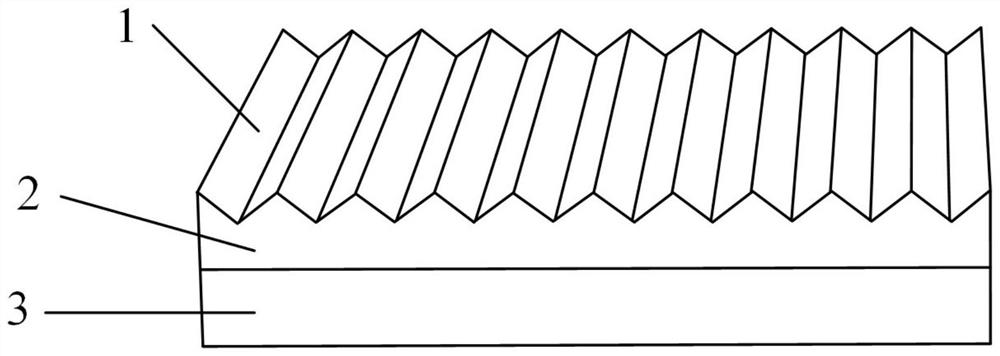

[0031] As a possible implementation, such as Figure 2-4 As shown, the sub-wavelength biomimetic microstructure 1 also includes cylinders, V-shaped grooves, pyramids and the like.

[0032] B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com