Negative electrode material, preparation method thereof and lithium ion battery

A lithium-ion battery, negative electrode material technology, applied in the direction of lithium battery, negative electrode, electrode manufacturing, etc., can solve the problem that the material cycle performance is difficult to meet the application requirements, the grain size is controlled at a suitable size, silicon and lithium silicate grains Large and other problems, to achieve good lithium ion conductivity, good rate performance, and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

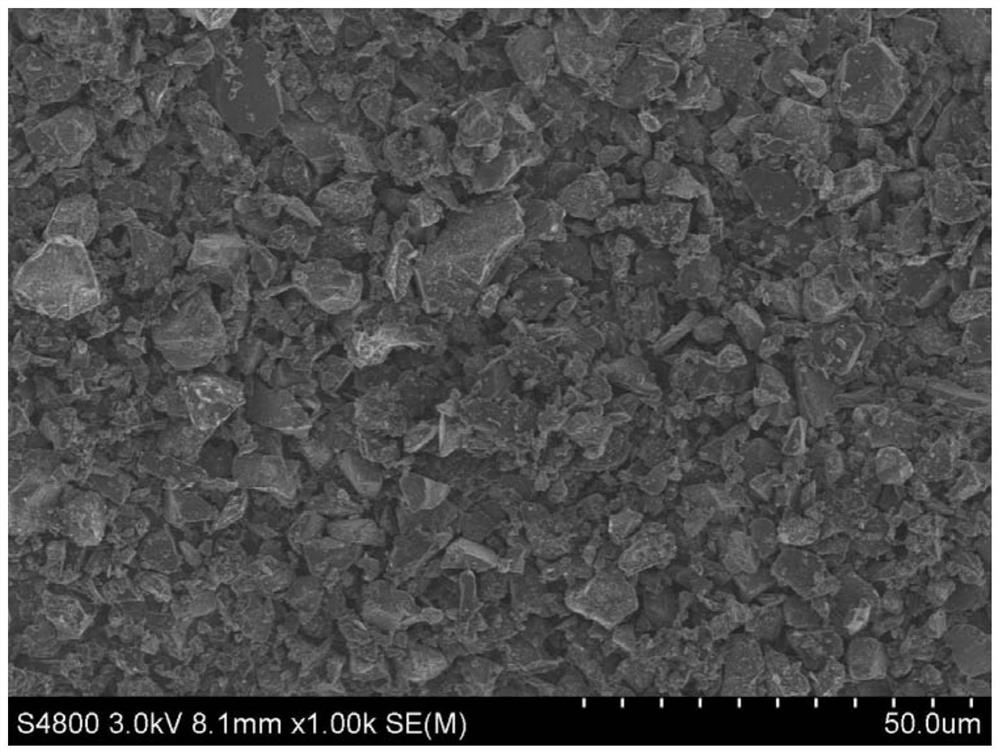

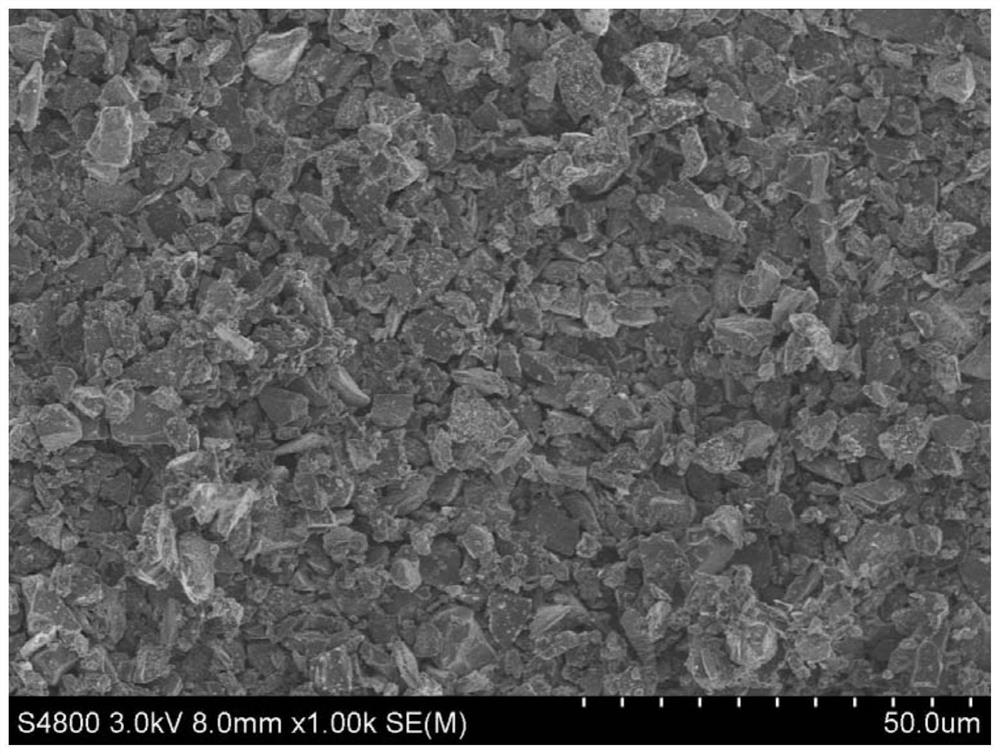

Image

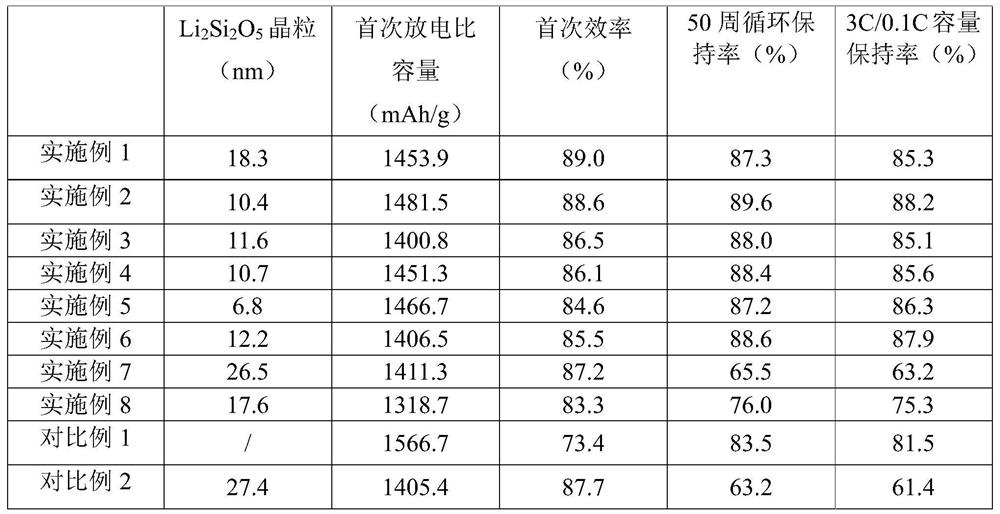

Examples

Embodiment 1

[0052] The present embodiment prepares the negative electrode material according to the following method:

[0053] (1) Take 500 g of silicon oxycarbide coated on the surface with a carbon content of 3% wt, and heat-treat it at 700° C. for 4 hours under an argon atmosphere to obtain silicon dioxide after heat treatment;

[0054] (2) Under an argon atmosphere, the heat-treated silicon oxide and lithium metal are uniformly mixed in a mixing device at a molar ratio of 1.5:1 to obtain silicon oxide containing lithium inside;

[0055] (3) Under an argon atmosphere, sinter the silicon oxide containing lithium at 600° C. for 6 hours, and pickle the sintered product to obtain the negative electrode material.

[0056] The negative electrode materials prepared in this example include nano-silicon, silicon oxide and crystalline Li 2 Si 2 o 5 , the silicon oxide is SiOx, x is 0.2, nano-silicon is uniformly dispersed in SiOx and Li 2 Si 2 o 5 Among them, the average particle diameter ...

Embodiment 2

[0060] The present embodiment prepares the negative electrode material according to the following method:

[0061] (1) Take 500 g of silicon oxycarbide coated on the surface with a carbon content of 3% wt, and heat-treat it at 800° C. for 4 hours under an argon atmosphere to obtain silicon dioxide after heat treatment;

[0062] (2) Under an argon atmosphere, the heat-treated silicon oxide and lithium metal are uniformly mixed in a mixing device at a molar ratio of 1.5:1 to obtain silicon oxide containing lithium inside;

[0063] (3) Under an argon atmosphere, sinter the silicon oxide containing lithium at 600° C. for 6 h, and pickle the sintered product to obtain the final negative electrode material.

[0064] The negative electrode materials prepared in this example include nano-silicon, silicon oxide and crystalline Li 2 Si 2 o 5 , silicon oxide is SiOx, x is 0.3, nano-silicon is uniformly dispersed in SiOx and Li 2 Si 2 o 5 Among them, the average particle size of nan...

Embodiment 3

[0068] The present embodiment prepares the negative electrode material according to the following method:

[0069] (1) Take 300 g of surface-coated silicon oxide with carbon content of 10% wt and heat-treat it at 900° C. for 10 hours under a nitrogen atmosphere to obtain silicon oxide after heat treatment;

[0070] (2) Under a nitrogen atmosphere, the heat-treated silicon dioxide and lithium carbonate are uniformly mixed in a mixing device at a molar ratio of 4:1 to obtain silicon oxide containing lithium inside;

[0071] (3) Under a nitrogen atmosphere, sinter the silicon oxide containing lithium at 800° C. for 8 hours, and pickle the sintered product to obtain the final negative electrode material.

[0072] The negative electrode materials prepared in this example include nano-silicon, silicon oxide and crystalline Li 2 Si 2 o 5 , silicon oxide is SiOx, x is 0.7, nano-silicon is uniformly dispersed in SiOx and Li 2 Si 2 o 5 Among them, the average particle size of nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com