Broad bean sauce rich in soybean oligosaccharides and preparation process thereof

A technology of soybean oligosaccharide and preparation process, which is applied to bacteria, yeast-containing food ingredients, Lactobacillus and other directions used in food preparation, can solve problems such as insufficient glucosidase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

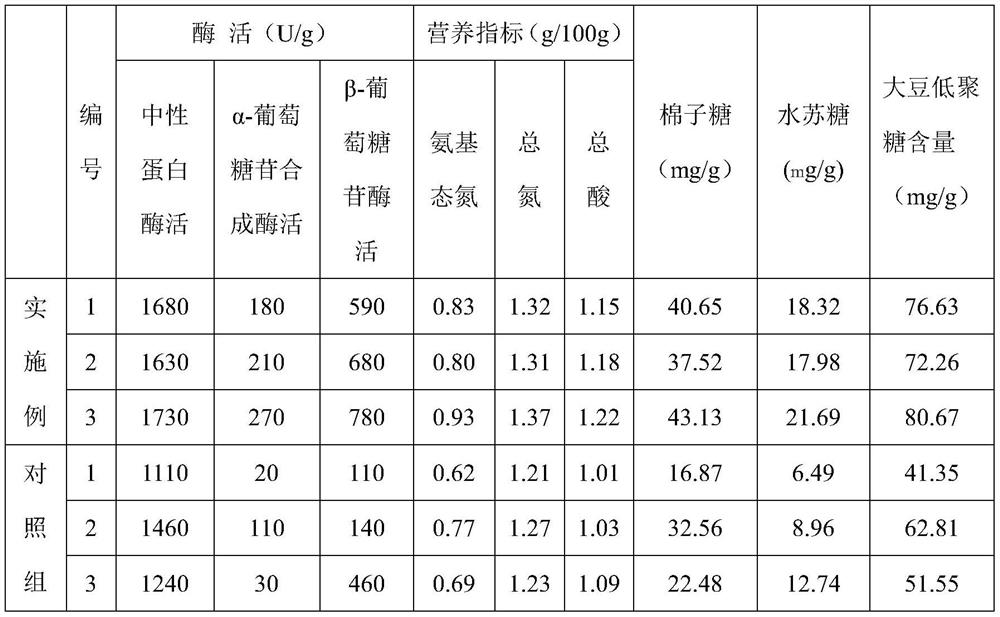

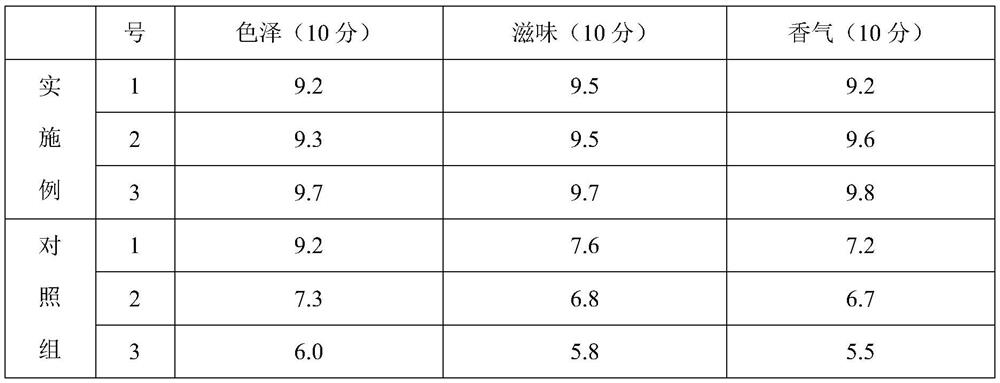

Examples

Embodiment 1

[0025] All strains described in the present invention can be purchased through commercial channels.

[0026] Example 1

[0027] A preparation process of broad bean paste rich in soybean oligosaccharides, the concrete steps are as follows:

[0028] (1) Douban pretreatment: select peeled watercress and flour as raw materials, the mass ratio is 6:4, soak the watercress with a strong-flavor tail wine with an alcohol content of 12% (V / V) at 35°C, and the liquid surface 5cm higher than broad bean flaps, soak for 6 hours, drain, mix with flour and cook at 115°C for 15 minutes.

[0029] (2) Preparation of koji: when the raw material is cooled to 30°C, add 1‰ Aspergillus oryzae spore powder according to the weight of the koji, and add Paenibacillus lactis CICC 10358 2×10 according to the weight of the koji 5 hours after making the koji. 3 pcs / g raw material, pine for the first time in 12 hours, and insert halotolerant Lactobacillus plantarum CICC 20039 2×10 at the same time 3 1 / g raw ...

Embodiment 2

[0033] A preparation process of broad bean paste rich in soybean oligosaccharides, the concrete steps are as follows:

[0034] (1) Douban pretreatment: select peeled watercress and flour as raw materials, with a mass ratio of 6:4, soak the watercress with Luzhou-flavored tail wine with an alcohol content of 18% (V / V) at 40°C, and the liquid surface 10cm higher than broad bean flap, soak for 10h, drain, mix with flour, cook at 115°C for 15min.

[0035] (2) Preparation of finished koji: when the raw materials are cooled to 30°C, add 5‰ Aspergillus oryzae spore powder according to the weight of the koji, and add Paenibacillus lactis CICC 10358 4×10 according to the weight of the koji 6 hours after making the koji. 5 pcs / g raw material, pine song for the first time in 14 hours, and insert halotolerant Lactobacillus plantarum CICC 20039 2×10 at the same time 5 1 / g raw material, 22h carry out the second loose koji, koji making 40h finishes, the humidity of the koji room is kept at ...

Embodiment 3

[0039] A preparation process of broad bean paste rich in soybean oligosaccharides, the concrete steps are as follows:

[0040] (1) Douban pretreatment: select peeled watercress and flour as raw materials, with a mass ratio of 7:3, soak the douban with a sauce-flavored tail wine with an alcohol content of 15% (V / V) at 35°C, and the liquid surface 10cm higher than broad bean, soak for 8 hours, drain, mix with flour, cook at 115°C for 15 minutes.

[0041] (2) Preparation of koji: when the raw material is cooled to 35°C, add 3‰ Aspergillus oryzae spore powder according to the weight of the koji, and add Paenibacillus lactis CICC 10358 7×10 according to the weight of the koji 6 hours after making the koji. 4 pcs / g raw material, pine song for the first time in 14 hours, and insert halotolerant Lactobacillus plantarum CICC 20039 2×10 at the same time 4 1 / g raw material, 24h is carried out the second loose koji, koji making 44h finishes, and the humidity of the koji room is maintaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com