Preparation method of filter screen for filtering lampblack

A filter screen and oil fume technology, which is applied in the field of air purification, can solve the problems of affecting the filtering effect of the filter material and the easy occurrence of holes in the dispersion liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

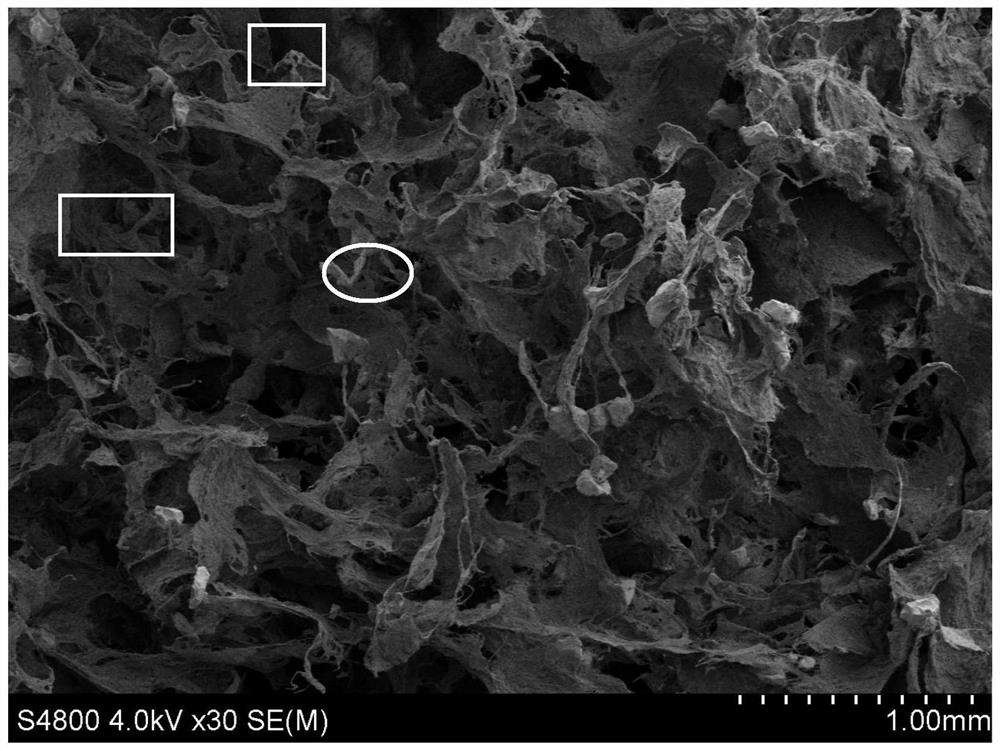

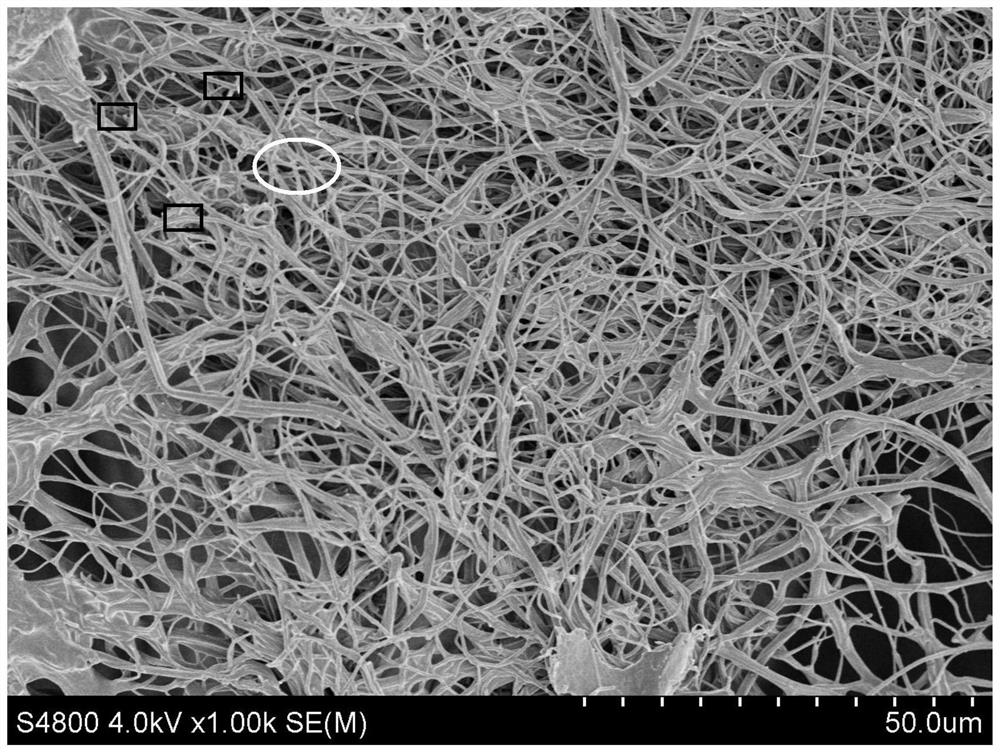

Image

Examples

Embodiment 1

[0035] The filter screen for filtering cooking fume of this preferred embodiment comprises the following steps:

[0036] (1) Preparation of spinning solution: disperse 0.2g of hydrophilic nano fumed silica particles (purchased from Shandong Hongxing Silica Co., Ltd.) in 70mL of N,N-dimethylacetamide DMAC and 10ml Ultrasonic vibration in acetone for 30min to obtain a dispersion, then 18g of polyacrylonitrile PAN (purchased from Hubei Dechao Chemical Co., Ltd.) was added to the above dispersion, stirred in a water bath at 70°C for 2h at a speed of 200r / min, and prepared into PAN / SiO 2 solution, then add 4g of polyurethane PU (Wanhe Chemical Group Co., Ltd.), and continue to stir in a water bath at 70°C for 1h until the dissolution is complete to obtain a spinning solution with a solid content of 21.5wt%;

[0037](2) The spinning liquid is defoamed or left standing for 12 hours before spinning, and the PET non-woven fabric is used as the collecting base cloth to carry out elect...

Embodiment 2

[0045] The filter screen for filtering cooking fume of this preferred embodiment comprises the following steps:

[0046] (1) Preparation of spinning solution: Add 20g of polystyrene PS (purchased from LG Chemicals) into 80mL of N,N-dimethylformamide DMF, stir in a water bath at 70°C for 2h, with a rotation speed of 200r / min, and prepare into a PS solution, then add 2g polyvinyl butyral PVB (Shandong Kepler Biotechnology Co., Ltd.), continue to stir in a water bath at 70° C. for 1 h until the dissolution is complete, and obtain a spinning solution with a solid content of 21.5%, and then spin at 110 Heating at 100°C for 2 hours for thermal crosslinking, the crosslinking agent components will melt after heating, and the overlapping parts of the fibers will form bonding points, so that the airgel after freeze-drying has better support and is not easy to collapse;

[0047] (2) The spinning liquid is defoamed or left standing for 12 hours before spinning, and the PP non-woven fabric...

Embodiment 3

[0054] The filter screen for filtering cooking fume of this preferred embodiment comprises the following steps:

[0055] (1) Preparation of spinning solution: disperse 0.05g of hydrophobic gas-phase polytetrafluoroethylene PTFE (purchased from McLean's reagent) in 80mL of N,N-DMA and ultrasonically vibrate for 30min to obtain a dispersion, and then 15g of polymer containing fluorine Polyurethane FPU (purchased from Wanhe Chemical Group Co., Ltd.) and 1 g of hydroxyethyl carboxymethyl cellulose (HECMC) were added to the aforementioned dispersion, stirred in a water bath at 70°C for 2 h at a speed of 200 r / min, and prepared into an FPU solution , until the dissolution is complete, obtaining a spinning solution with a solid content of 16.5wt%;

[0056] (2) The spinning liquid is defoamed or left standing for 12 hours before spinning, and the ES non-woven fabric is used as the collection base cloth to carry out electrospinning on the spinning liquid: inject the prepared spinning l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com