Waterborne polyurethane adhesive with long persistent viscosity and preparation method thereof

A water-based polyurethane and adhesive technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of long activation time, high activation temperature, and short sticking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

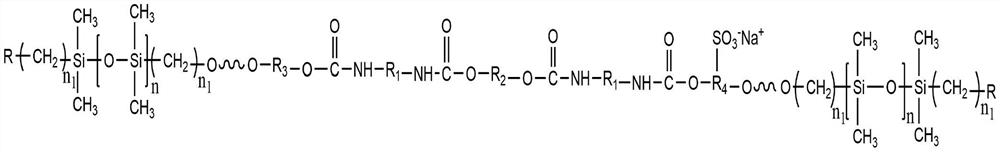

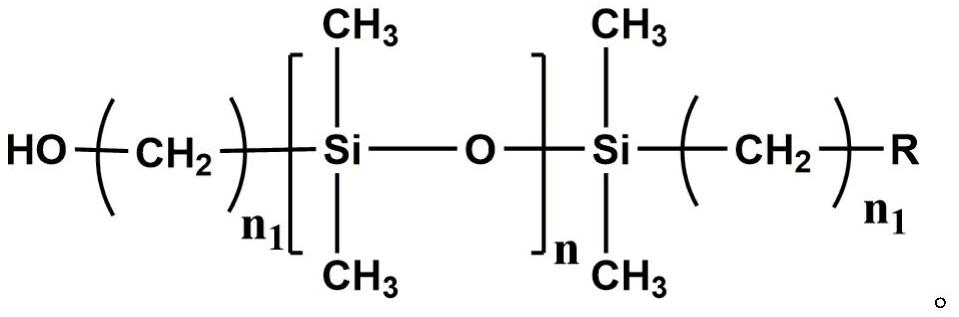

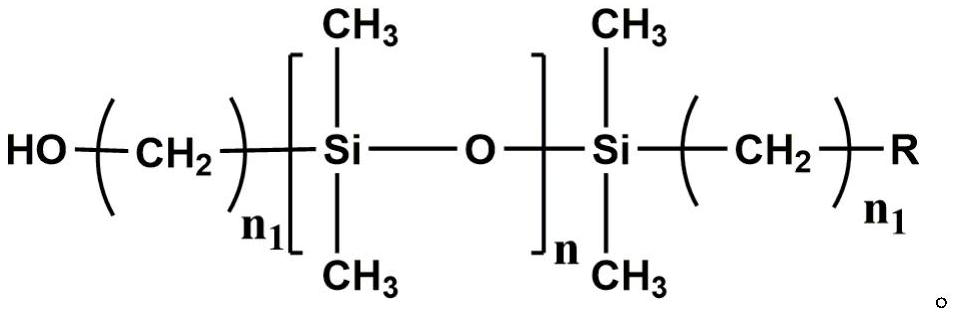

[0038] A kind of preparation method of long-lasting viscous water-based polyurethane adhesive containing Si-O-Si structure (telechelic structure) at both ends

[0039] In parts by mass, its raw materials include: 22.23 parts of isophorone diisocyanate, 111.2 parts of polybutylene adipate, 22.8 parts of polyneopentyl adipate, 0.72 parts of 1,4-butanediol Parts, BY-3306B 7.82 parts, single-ended hydroxymethyl polydimethylsiloxane 14.22 parts, dibutyltin dilaurate 0.05 parts, deionized water 210 parts, acetone 170 parts.

[0040] The specific steps of the preparation method are:

[0041]f. According to the above-mentioned parts by mass, vacuum dehydrate polybutylene adipate and polyneopentyl adipate at 120°C for 1.0-1.5h, cool down to 75°C and add isophorone di Isocyanate, nitrogen protection reaction at 80-85°C for 2.5h to obtain a prepolymer with an -NCO group at the end;

[0042] g. Add 10-20 parts of solvent acetone to the obtained prepolymer to adjust the viscosity, and lo...

Embodiment 2

[0054] A kind of preparation method of long-lasting viscous water-based polyurethane adhesive containing Si-O-Si structure (telechelic structure) at both ends

[0055] In parts by mass, its raw materials include: 11.12 parts of isophorone diisocyanate, 8.41 parts of hexamethylene diisocyanate, 111.2 parts of polybutylene adipate diol, 22.2 parts of polycaprolactone diol 0.72 parts of 1,4-butanediol, 5.5 parts of BY-3306, 13.77 parts of single-ended hydroxymethyl polydimethylsiloxane, 0.05 parts of dibutyltin dilaurate, 200 parts of deionized water, and 170 parts of acetone.

[0056] The preparation method is the same as in Example 1.

Embodiment 3

[0058] A kind of preparation method of the long-lasting viscous water-based polyurethane adhesive that contains Si-O-Si structure (telechelic structure) at both ends:

[0059] In terms of parts by mass, its raw materials include: 10.09 parts of 1,6-hexamethylene diisocyanate, 10.48 parts of 4,4-dicyclohexane diisocyanate, 115.2 parts of neopentyl glycol adipate, 1, 0.9 parts of 4-butanediol, 28.8 parts of BY-3301, 16.2 parts of single-ended hydroxymethyl polydimethylsiloxane, 0.03 parts of stannous octoate, 220 parts of deionized water, and 180 parts of acetone.

[0060] The specific steps of the preparation method are:

[0061] a. According to the above-mentioned parts by mass, vacuum dehydrate poly(neopentyl glycol adipate) diol at 120°C for 1.0-1.5h, cool down to 75°C and add 1,6-hexamethylene diisocyanate, Reaction under nitrogen protection at 80-85°C for 2.5 hours to obtain a prepolymer with an -NCO group at the end;

[0062] b. Add 10-20 parts of solvent acetone to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com