Magnetic response Janus nano-particles based on oil-in-water high internal phase emulsification and preparation method of magnetic response Janus nano-particles

A nanoparticle, magnetic response technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as loss of magnetism, ferric tetroxide is easily soluble in acidic solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing magnetically responsive Janus nanoparticles based on oil-in-water high internal phase emulsification, the steps are as follows:

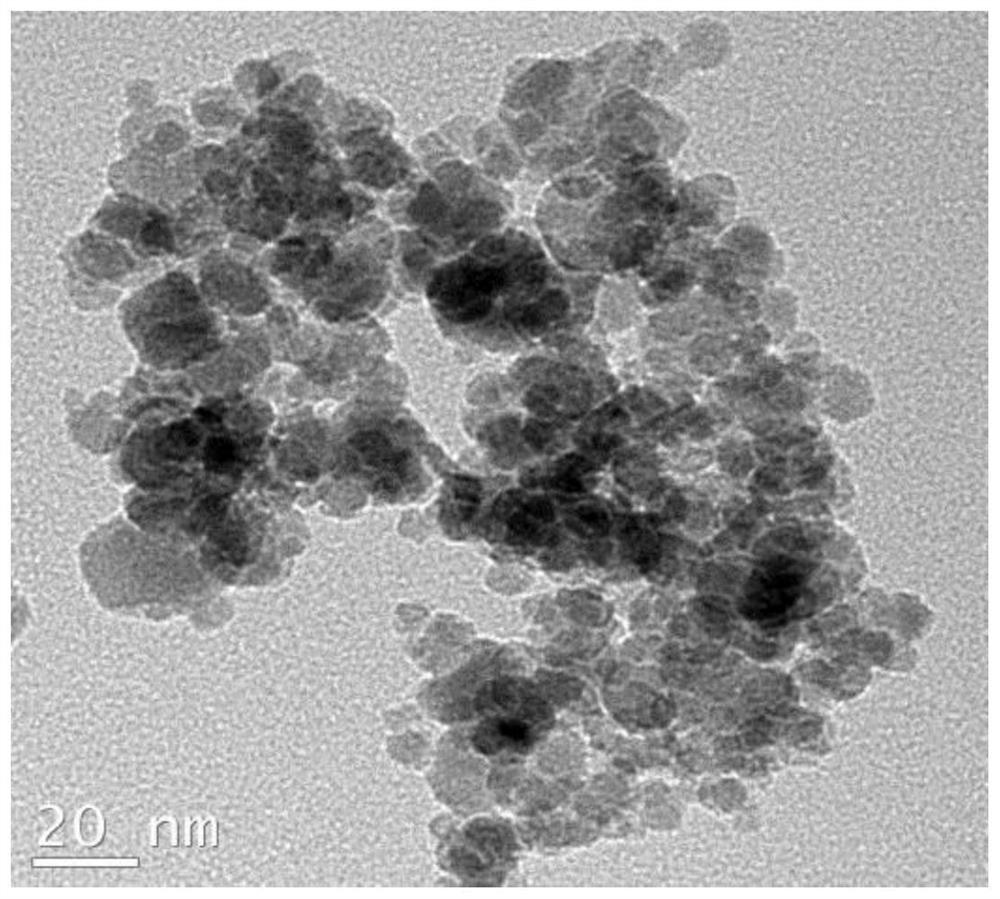

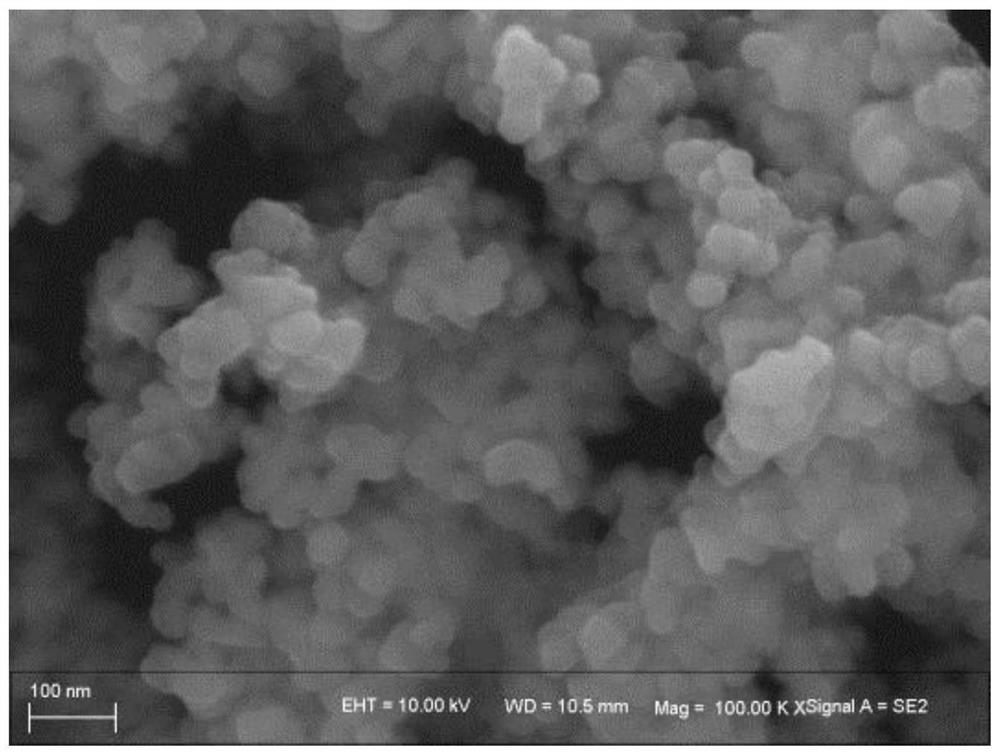

[0038] (1) Preparation of magnetic nanoparticles Fe 3 o 4

[0039] Take 5.4g of FeCl 3 ·6H 2 O and 2.05 g FeCl 2 4H 2 Dissolve O in 100ml of distilled water, stir and dissolve with nitrogen gas, then under the condition of ultrasonic oscillation, add ammonia water with a mass concentration of 20% at a constant temperature of 75°C drop by drop until the pH of the solution is 10, continue to react for 40min, rinse repeatedly with distilled water and separate with a magnet, pump Dry at 80°C for 24 hours under vacuum.

[0040] (2) Preparation of core-shell nanoparticle Fe 3 o 4 @SiO 2

[0041] Take 1g of magnetic nanoparticles Fe 3 o 4 Ultrasonic dispersion in a mixed solution of 80ml of absolute ethanol and 10ml of distilled water, continue to add 3ml of ammonia water with a mass concentration of 20% and stir e...

Embodiment 2

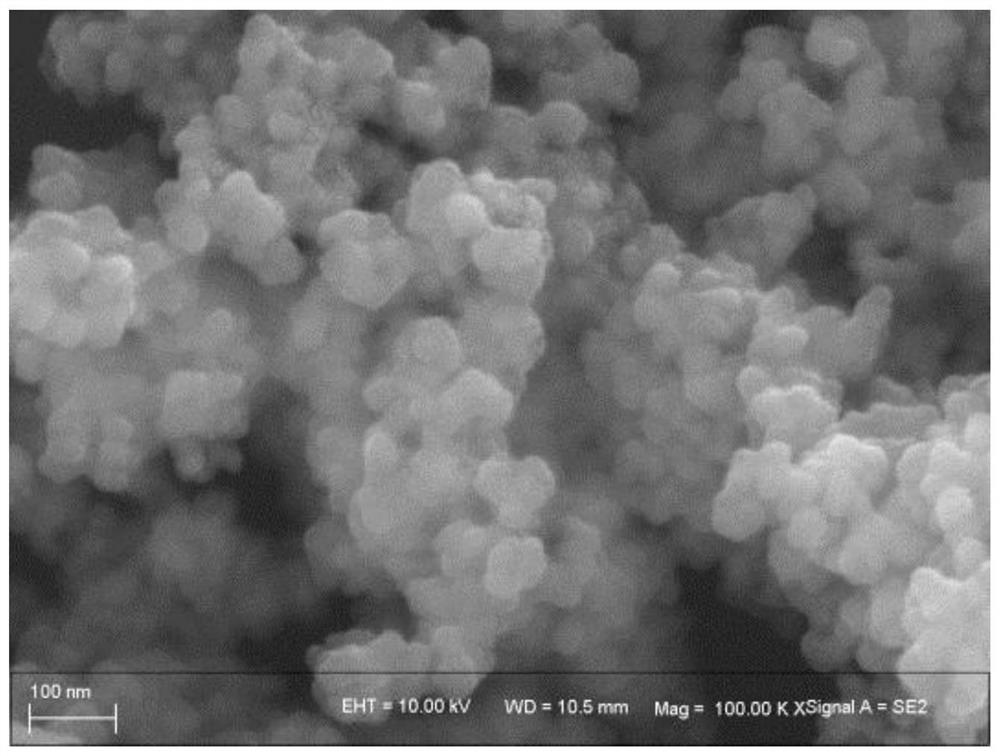

[0055] Preparation of non-ionic magnetic Janus nanoparticles [(CH 2 OCH)-CH 2 -O]-Fe 3 o 4 @SiO 2 -octyl, the steps are as follows:

[0056] Steps (1)-(3) are the same as in Example 1.

[0057] Step (4) gets 1.1g by the magnetic nanoparticle Fe of paraffin semi-wrapped 3 o 4 @SiO 2 Stir and disperse in a mixed solution of 80ml of absolute ethanol and 10ml of distilled water, continue to add 2ml of 20% ammonia water and stir evenly, then add 0.12g of n-octyltrimethoxysilane drop by drop, react at a constant temperature of 40°C for 20h, and dissolve the paraffin with chloroform Particles release nanoparticle Fe 3 o 4 @SiO 2 -octyl, then washed several times with absolute ethanol and distilled water, and dried at 80°C for 24 hours for later use.

[0058] Step (5) gets 0.1g nanoparticle Fe3 o 4 @SiO 2 Ultrasonic dispersion of -octyl in a mixed solution of 80ml of absolute ethanol and 10ml of distilled water, continue to add 2ml of 20% ammonia water and stir evenly, th...

Embodiment 3

[0061] Preparation of 2# Anionic Magnetic Janus Nanoparticles HOOC-Fe 3 o 4 @SiO 2 -propyl, the steps are as follows:

[0062] Steps (1)-(3) are the same as in Example 1.

[0063] Step (4) gets 1.1g by the magnetic nanoparticle Fe of paraffin semi-wrapped 3 o 4 @SiO 2 Stir and disperse in a mixed solution of 80ml of absolute ethanol and 10ml of distilled water, continue to add 2ml of 20% ammonia water and stir evenly, then add 0.1g of propyltrimethoxysilane dropwise, react at a constant temperature of 40°C for 20h, and dissolve the paraffin particles with chloroform released nanoparticles Fe 3 o 4 @SiO 2 -propyl, then washed several times with absolute ethanol and distilled water, and dried at 80°C for 24 hours for later use.

[0064] Step (5) gets 0.1g nanoparticle Fe 3 o 4 @SiO 2 -propyl ultrasonically dispersed in a mixed solution of 80ml of absolute ethanol and 10ml of distilled water, continue to add 2ml of 20% ammonia water and stir evenly, then add 0.1g of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com