Wool and cashmere large biological fiber containing active ingredients of pericarpium citri reticulatae, orange and pomelo and preparation method of wool and cashmere large biological fiber

A technology of active ingredients and biological fibers, which is applied in the preparation of cashmere large biological fibers and wool field, can solve the problems of non-bacterial properties of fabrics, easy breeding of bacteria, and yellowing of wool fibers when stored.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

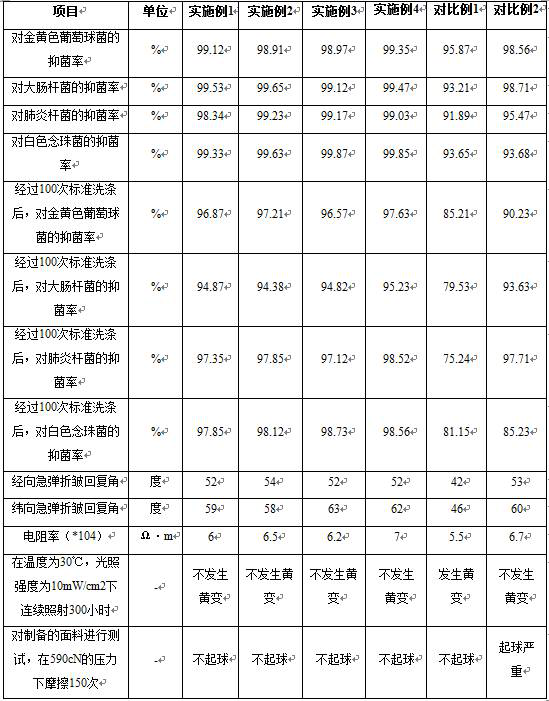

Examples

Embodiment 1

[0041] A method for preparing wool macrobiological fibers containing active ingredients of tangerine peel, orange and pomelo, comprising soaking and swelling, low temperature treatment, biomodification, anti-pilling treatment and anti-moth treatment.

[0042] For soaking and swelling, soak the wool fiber in an acetic acid solution with a mass fraction of 7%, soak it for 3 hours at 40°C, then add white carbon black to the acetic acid solution, and then perform ultrasonic oscillation. After oscillating for 5 hours, place the wool fiber in Dry at 40°C to obtain swollen wool fibers.

[0043] Among them, the mass ratio of wool fiber: 7% acetic acid solution: white carbon black is 5:50:2.

[0044] For the low temperature treatment, place the wool fiber at -15°C, add dodecyltrimethylammonium chloride, and then carry out ultraviolet treatment. The ultraviolet wavelength is 250nm, the ultraviolet lamp power is 50W, and the ultraviolet action time is 30min, and then the The wool fiber ...

Embodiment 2

[0064] A method for preparing wool macrobiological fibers containing active ingredients of tangerine peel, orange and pomelo, comprising soaking and swelling, low temperature treatment, biomodification, anti-pilling treatment and anti-moth treatment.

[0065] For the soaking and swelling, soak the wool fiber in an acetic acid solution with a mass fraction of 7%, soak it at 45°C for 3.5 hours, then add white carbon black to the acetic acid solution, and then perform ultrasonic oscillation, and shake the wool fiber for 5.5 hours Dry at 42°C to obtain swollen wool fibers.

[0066] Among them, the mass ratio of wool fiber: 7% acetic acid solution: white carbon black is 6:52:3.

[0067] For the low temperature treatment, place the wool fiber at -10°C, add dodecyltrimethylammonium chloride, and then perform ultraviolet treatment. The ultraviolet wavelength is 270nm, the ultraviolet lamp power is 60W, and the ultraviolet action time is 35min, and then Dry the wool fiber at 52°C to o...

Embodiment 3

[0087] A method for preparing wool macrobiological fibers containing active ingredients of tangerine peel, orange and pomelo, comprising soaking and swelling, low temperature treatment, biomodification, anti-pilling treatment and anti-moth treatment.

[0088] For soaking and swelling, soak the wool fiber in an acetic acid solution with a mass fraction of 7%, soak it at 50°C for 4 hours, then add white carbon black to the acetic acid solution, and then perform ultrasonic oscillation. After oscillating for 6 hours, place the wool fiber in Dry at 45°C to obtain swollen wool fibers.

[0089] Among them, the mass ratio of wool fiber: 7% acetic acid solution: white carbon black is 7:55:3.

[0090] For the low temperature treatment, place the wool fiber at -5°C, add dodecyltrimethylammonium chloride, and then perform ultraviolet treatment. The ultraviolet wavelength is 290nm, the ultraviolet lamp power is 70W, and the ultraviolet action time is 40min, and then Drying the wool fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com