Method for depositing aluminum oxide film in PERC battery

A deposition method and technology of aluminum oxide film, which are applied in the field of solar cells to achieve the effect of reducing the proportion of EL black edges, improving uniformity and avoiding CVD reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

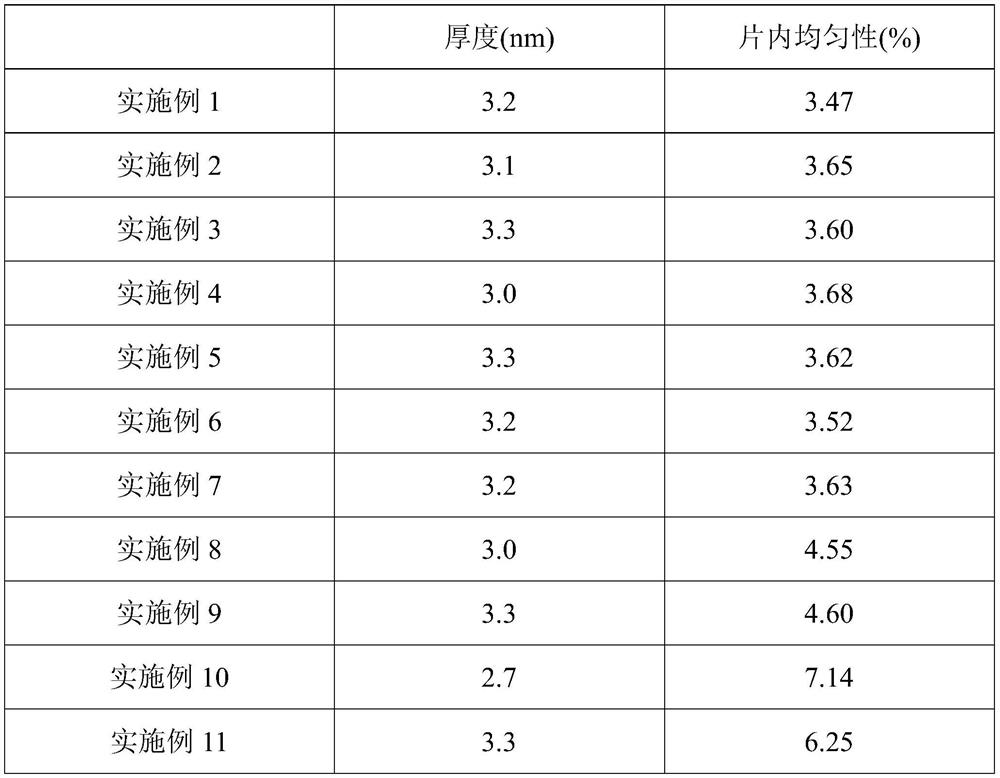

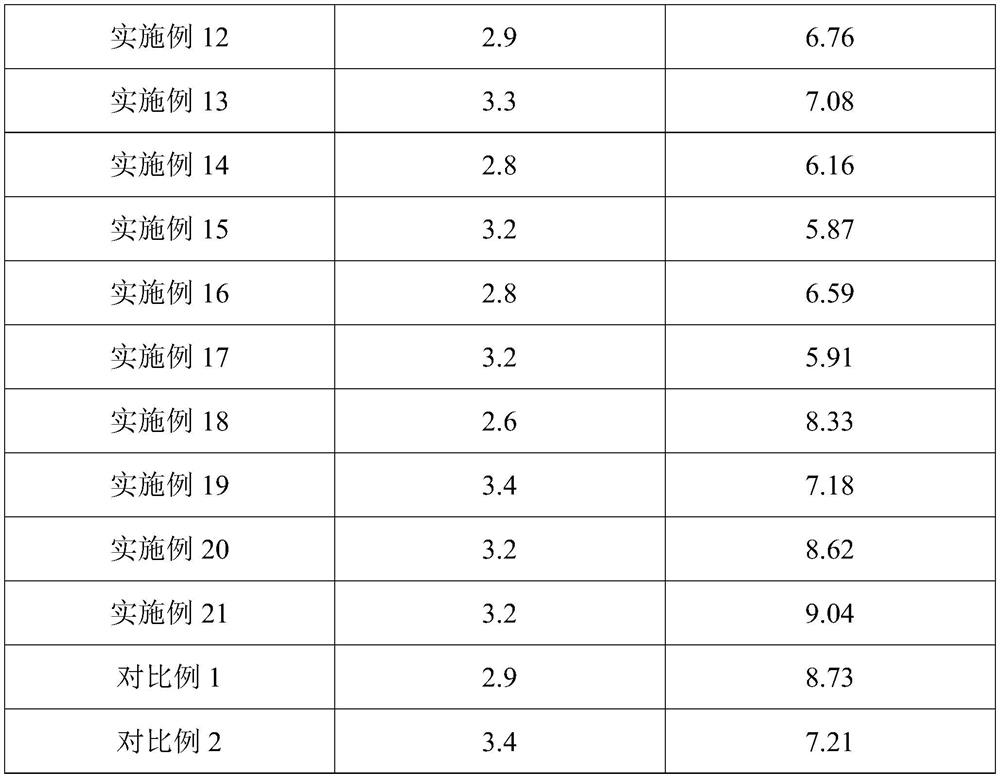

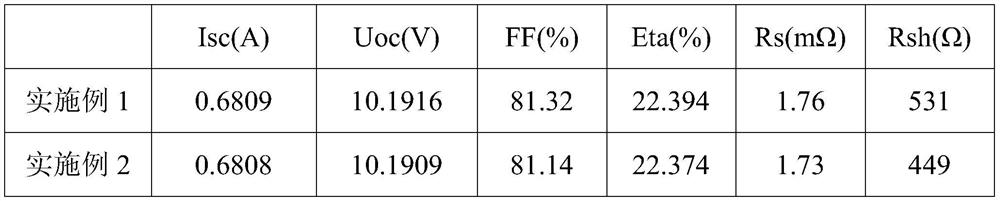

Examples

Embodiment 1

[0040] This embodiment provides a method for depositing an aluminum oxide film in a PERC battery, the deposition method comprising the following steps:

[0041] Insert the oxidized and annealed cells into the aluminum boat and send them into the ALD tube furnace. Vacuumize until the absolute pressure inside the furnace tube does not exceed 1.2mbar and the absolute pressure outside the furnace tube is 6mbar, and the temperature rises at a rate of 0.6°C / s to 250°C, then alternately feed trimethylaluminum and H 2 O is deposited, and after the deposition is completed, the nitrogen gas is passed to break the vacuum, and the deposition of the aluminum oxide film in the PERC cell is completed; the number of times of the alternate feeding is 27 times;

[0042] During a single feeding process, the pulse time of trimethylaluminum is 3s, the purge time is 6s, and the flow rate of trimethylaluminum is 18sccm;

[0043] During a single pass, H 2 The pulse time of O is 3s, the purge time i...

Embodiment 2

[0046] This embodiment provides a method for depositing an aluminum oxide film in a PERC battery, the deposition method comprising the following steps:

[0047] Insert the oxidized and annealed cells into the aluminum boat and send them into the ALD tube furnace. Vacuumize until the absolute pressure inside the furnace tube does not exceed 1.2mbar and the absolute pressure outside the furnace tube is 4mbar, and the temperature rises at a rate of 0.55°C / s to 245°C, then alternately feed trimethylaluminum and H 2 O is deposited, and after the deposition is completed, the nitrogen gas is passed to break the vacuum, and the deposition of the aluminum oxide film in the PERC cell is completed; the number of times of the alternate feeding is 24 times;

[0048] During a single feeding process, the pulse time of trimethylaluminum is 4s, the purge time is 8s, and the flow rate of trimethylaluminum is 10sccm;

[0049] During a single pass, H 2 The pulse time of O is 4s, the purge time ...

Embodiment 3

[0052] This embodiment provides a method for depositing an aluminum oxide film in a PERC battery, the deposition method comprising the following steps:

[0053] Insert the oxidized and annealed cells into the aluminum boat and send them into the ALD tube furnace. Vacuumize until the absolute pressure inside the furnace tube does not exceed 1.2mbar and the absolute pressure outside the furnace tube is 8mbar. The temperature rises at a rate of 0.7°C / s to 255°C, then alternately feed trimethylaluminum and H 2 O is deposited, and after the deposition is completed, the nitrogen gas is passed to break the vacuum, and the deposition of the aluminum oxide film in the PERC cell is completed; the number of times of the alternate feeding is 30 times;

[0054] During a single feeding process, the pulse time of trimethylaluminum is 2s, the purge time is 4s, and the flow rate of trimethylaluminum is 24sccm;

[0055] During a single pass, H 2 The pulse time of O is 2s, the purge time is 8s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com