Method for modifying polymeric membrane material through electron beam irradiation

An electron beam irradiation, polymer membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high cost, complex surface technology of covalently modified membrane materials, and difficulty in mass production. , to achieve the effect of restoring water flux, good storage and transportation and convenience of use, and durable anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

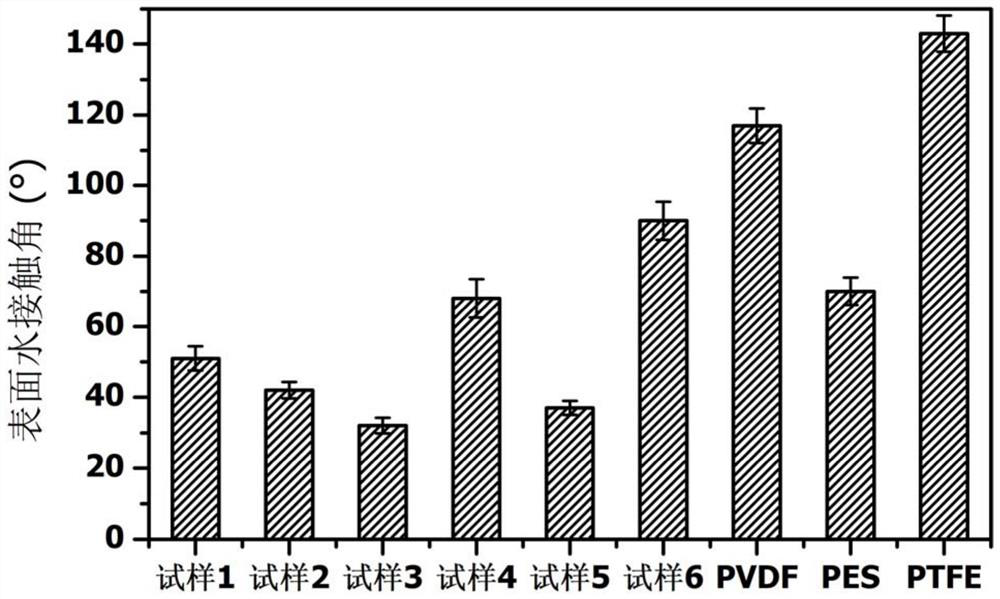

[0050] (1) Under mechanical stirring, 20 g of polyvinylpyrrolidone (PVP) powder was added into 80 g of deionized water, and heated to 60° C., and stirring was continued for 6 hours to obtain a 20% PVP aqueous solution.

[0051] (2) get 1g step (1) gained PVP aqueous solution and 5g deionized water, 4g ethanol and mix in beaker, obtain the PVP aqueous solution that concentration is 2%; Get 5 commercially available polyethersulfone flat membrane materials (PES, diameter About 5cm, pore size 0.45μm, about 0.1g / sheet) soaked in the above-mentioned concentration of 2% PVA aqueous solution for 1 hour.

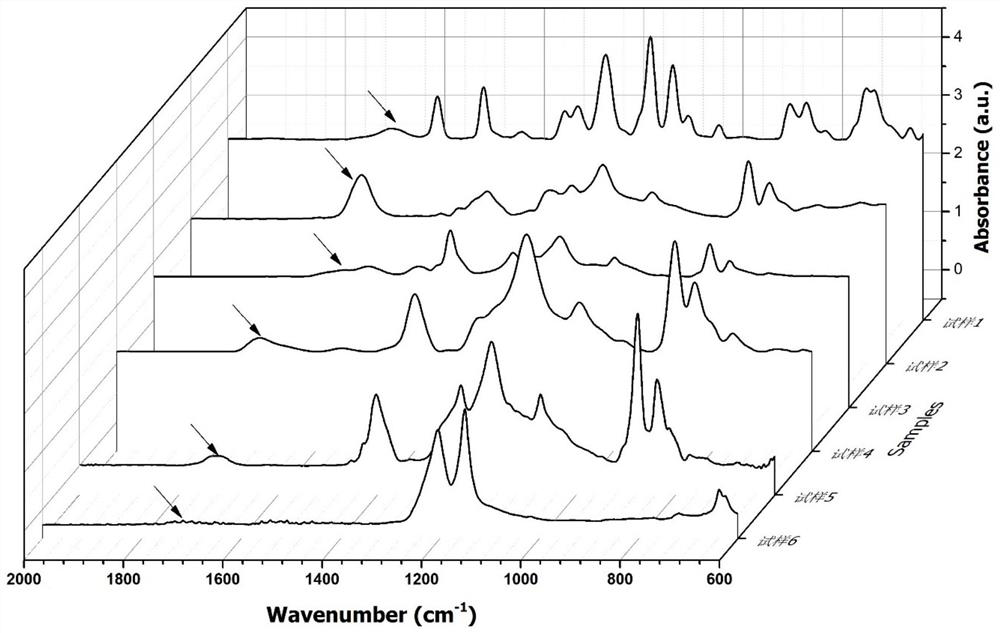

[0052] (3) the PES film material soaked in the PVP aqueous solution in the step (2) is taken out, and packed in a polyethylene ziplock bag; after sealing, send it into the electron accelerator irradiation room and carry out electron beam radiation treatment, and the absorbed dose is 150kGy, The dose rate is 2000kGy / hour; after the irradiation, unpack and rinse the irradiated PES memb...

Embodiment 2

[0055] (1) Under mechanical stirring, 20 g of polyvinylpyrrolidone (PVP) powder was added into 80 g of deionized water, and heated to 60° C., and stirring was continued for 6 hours to obtain a 20% PVP aqueous solution.

[0056] (2) get 2.5g step (1) gained PVP aqueous solution and 5g deionized water, 2.5g acetic acid and mix in beaker, obtain the PVP aqueous solution that concentration is 5%; Get 5 commercially available polyethersulfone flat membrane materials (PVDF , about 5 cm in diameter, 0.45 μm in pore size, about 0.1 g / piece) soaked in the above-mentioned 2% PVP aqueous solution for 1 hour.

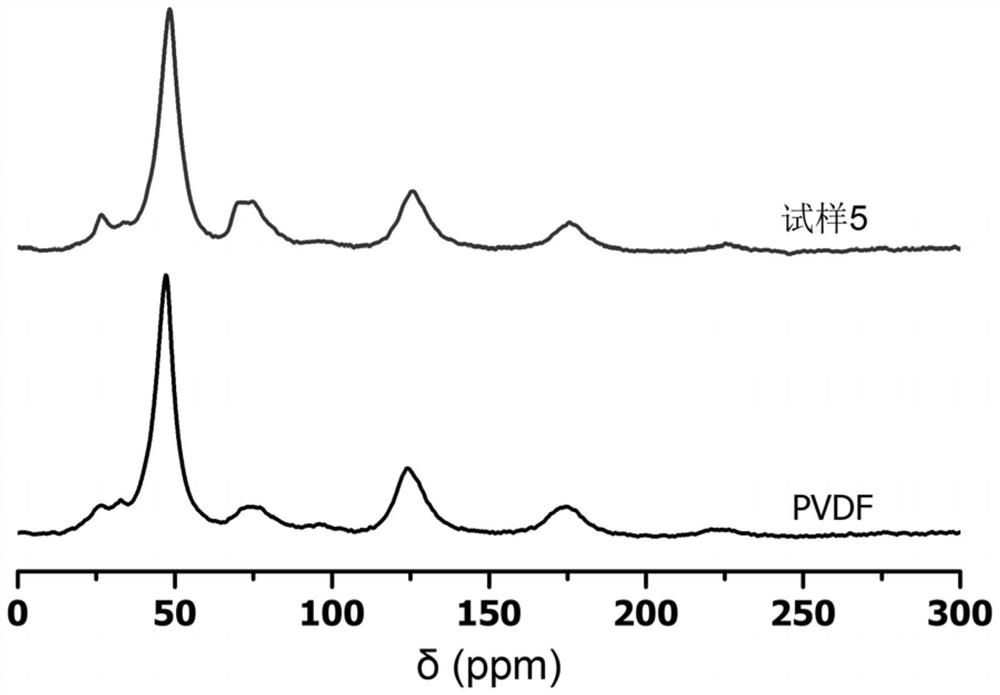

[0057] (3) the PVDF film material soaked in the PVP aqueous solution in the step (2) is taken out, and packed in the polyethylene ziplock bag; After sealing, send into the electron accelerator irradiation room and carry out electron beam radiation treatment, the absorbed dose is 200kGy, The dose rate is 2500kGy / hour; after the irradiation is completed, unpack and rinse the irradiat...

Embodiment 3

[0060] (1) Under mechanical stirring, 20g of polyvinylimine (PEI) was added to 80g of deionized water, and heated to 60°C, and the stirring was continued for 6 hours to obtain a PEI aqueous solution with a concentration of 20%;

[0061] (2) Get 3g step (1) gained PEI aqueous solution and 5g deionized water, 2g acetone, stir and mix in beaker, obtain the PEI aqueous solution that concentration is 6%; Get 10 commercially available PVDF flat membrane materials (diameter 5cm, aperture 0.45 μm, about 0.1 g / piece) soaked in the above diluted PEI aqueous solution for 6 hours.

[0062] (3) the PVDF film material soaked in the PEI aqueous solution in the step (2) is taken out, and is packed in the polyethylene vacuum packaging bag; After vacuum sealing, send into the electron accelerator irradiation room and carry out the electron beam radiation treatment, the absorbed dose is 500kGy, the dose rate is 5000kGy / hour; after the irradiation is completed, unpack and rinse the irradiated PVD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com