Device for preparing polyisobutylene maleic anhydride

A technology of maleic anhydride and polyisobutylene, which is applied in the direction of feeding devices, detailed information of chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve cumbersome maintenance, toxic dioxide and other substances , high free chlorine content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

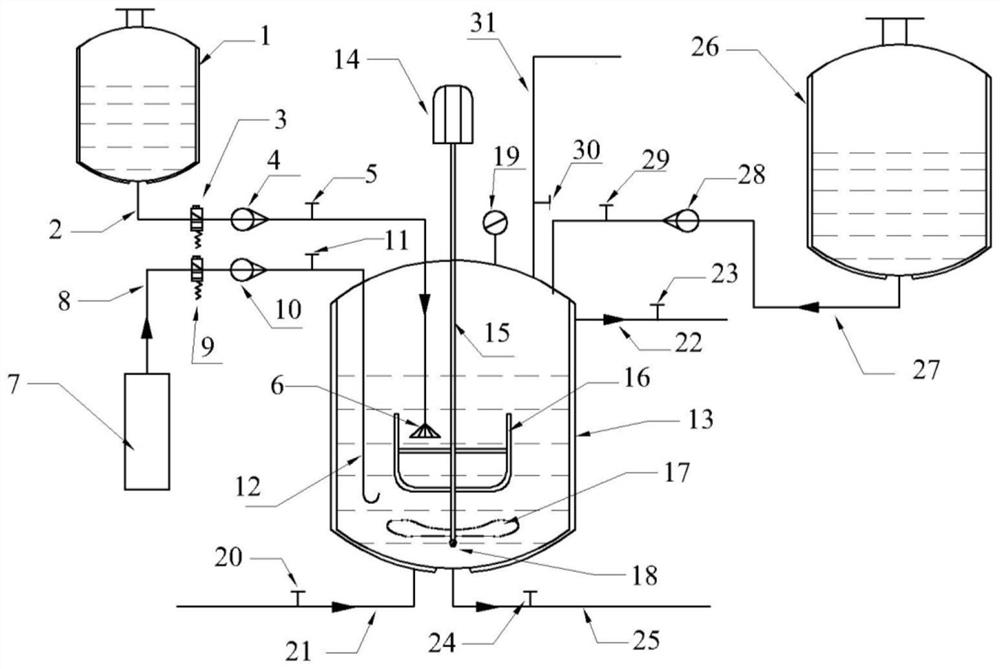

[0038] figure 1The micro-positive pressure device for preparing polyisobutylene maleic anhydride for this example includes maleic anhydride pre-storage and delivery system, polyisobutylene pre-storage and delivery system, inert gas micro-positive pressure delivery system and main reactor system. The maleic anhydride pre-storage and delivery system consists of a maleic anhydride storage tank 1, a maleic anhydride delivery pipe 2, a booster pump 3, a flow meter 4, a micro-positive pressure check valve 5 and an umbrella-shaped sprinkler head 6 in sequence. The maleic anhydride storage tank 1 has a heating system and a heat preservation system, the temperature inside the tank is 10-100°C, and the outer layer of the delivery pipe 2 has a heating coil and an insulation layer; the polyisobutylene pre-storage and delivery system is made of poly The isobutylene storage tank 26, the polyisobutylene feed pipeline 27, the flow meter 28 and the micro-positive pressure check valve 29 are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com