Solid base catalyst, preparation method thereof and application of solid base catalyst in synthesis of anisole

A solid base catalyst and anisole technology, applied in the chemical industry, can solve the problems of unstable loss of active components, short industrial life of catalysts, poor environmental tolerance of catalysts and easy deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

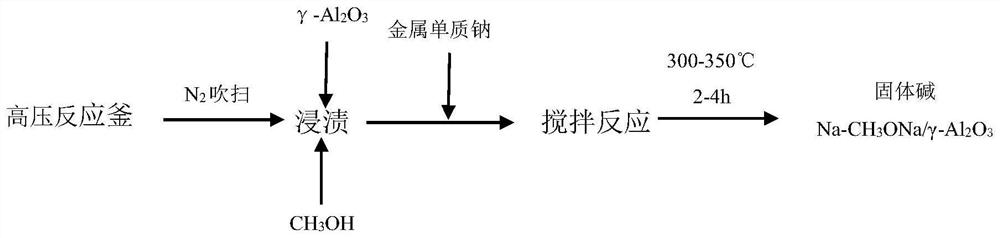

[0043] Such as figure 1 Shown, the preparation method of solid base catalyst of the present invention comprises the following steps:

[0044] Step 1, N 2 Purge and replace the air and trace moisture in the autoclave (GCF Dalian Automatic Control Equipment Factory) for 0.5-1h;

[0045] Step 2, weigh γ-Al with an analytical balance (FA1104N Shanghai Precision Scientific Instrument Co., Ltd.) 2 o 3 Add 50-150g (4N Shanghai Dibo Chemical Technology Co., Ltd.) into the autoclave, measure CH with a measuring cylinder 3 OH 80-100mL (AR Tianjin Ruijinte Chemicals Co., Ltd.) was slowly added to the γ-Al 2 o 3 moisten

[0046] Step 3, add 10-20g of metal elemental sodium (AR Jining Hengtai Chemical Co., Ltd.), open the high-pressure reactor, and stir the reaction at a temperature of 300-350°C and a pressure of 10-15MPa for 2-4h to obtain Na-CH 3 ONa / γ-Al 2 o 3 (YP / γ-Al 2 o 3 ) solid base catalyst.

preparation Embodiment 1

[0048] Step 1, N 2 Purge and replace the air and trace moisture in the autoclave for 1 hour;

[0049] Step 2, weigh γ-Al with an analytical balance 2 o 3 50g was added to the autoclave, and 80mL of methanol was measured by the graduated cylinder and slowly added to the autoclave;

[0050] Step 3, then add 10g of metal elemental sodium, open the autoclave, and react at a temperature of 300°C and a pressure of 15MPa for 2h to obtain Na-CH 3 ONa / γ-Al 2 o 3 (YP / γ-Al 2 o 3 ) solid base catalyst.

preparation Embodiment 2

[0052] Step 1, N 2 Purge and replace the air and trace moisture in the autoclave for 0.5h;

[0053] Step 2, weigh γ-Al with an analytical balance 2 o 3 80g was added to the autoclave, and 100mL of methanol was measured by the graduated cylinder and slowly added to the autoclave;

[0054] Step 3, then add 15g of metal elemental sodium, open the autoclave, and react for 3 hours at a temperature of 350°C and a pressure of 15MPa to obtain Na-CH 3 ONa / γ-Al 2 o 3 (YP / γ-Al 2 o 3 ) solid base catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com