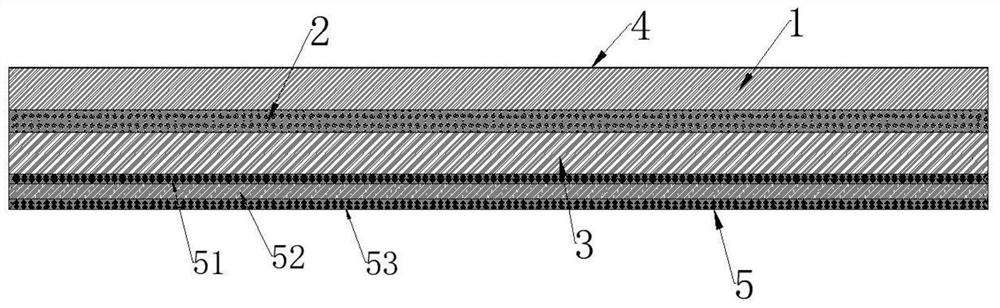

High-strength light-weight fireproof aluminum composite plate and preparation process thereof

An aluminum composite board and a preparation process technology, which is applied in the field of fireproof boards, can solve the problems of not improving the strength of the fireproof aluminum composite board, poor specification and dimensional stability, and restricting the fireproof aluminum composite board, so as to delay the thermal oxidation degradation process and achieve excellent fireproofing effect , Improve the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The high-strength lightweight fireproof aluminum composite board includes the following steps:

[0042] (1) Preparation of flame retardant core board:

[0043] 1) Preparation of modified hydrotalcite: Put the hydrotalcite in a muffle furnace and calcinate at 480 °C for 5.5 h to obtain the calcined product, which is stored in a desiccator; boil the distilled water until it boils and keep it in a slightly boiling state. Reflux, put the calcined product into slightly boiling distilled water and stir, then add the modifier immediately, adjust the pH to 10 with NaOH solution, and continue stirring for 3 h to obtain a mixed solution; place the mixed solution statically for aging until obvious The layered mixture was suction-filtered and washed with distilled water until the filtrate was neutral. The product was dried in a drying oven at 80°C, and the dried white solid was ground into powder to obtain the improved Sexual hydrotalcite;

[0044] 2) Melt mixing: the flame-retar...

Embodiment 2

[0049] The high-strength lightweight fireproof aluminum composite board includes the following steps:

[0050] (2) Preparation of flame retardant core board:

[0051] 3) Preparation of modified hydrotalcite: Put the hydrotalcite in a muffle furnace and calcinate at 500 °C for 5 h to obtain the calcined product, which is stored in a desiccator; boil the distilled water to boiling and keep it in a slightly boiling state while refluxing , put the calcined product into slightly boiling distilled water and stir, then add modifier immediately, adjust the pH to 10 with NaOH solution, and continue stirring for 3.5h to obtain a mixed solution; place the mixed solution statically for aging until obvious Layering, the layered mixture was suction filtered and washed with distilled water until the filtrate was neutral, the product was dried in a drying oven at 80°C, and the dried white solid was ground into powder to obtain the modified Hydrotalcite;

[0052] 4) Melt mixing: the flame-re...

Embodiment 3

[0057] The high-strength lightweight fireproof aluminum composite board includes the following steps:

[0058] (3) Preparation of flame retardant core board:

[0059] 5) Preparation of modified hydrotalcite: Put the hydrotalcite in a muffle furnace and calcinate at 480 °C for 5 h to obtain the calcined product, which is stored in a desiccator; boil the distilled water until it boils and keep it in a slightly boiling state. Reflux, put the calcined product into slightly boiling distilled water and stir, then immediately add a modifier, adjust the pH to 10 with NaOH solution, continue stirring for 4 hours, and obtain a mixed solution; place the mixed solution statically for aging until obvious Layering, the layered mixture was suction filtered and washed with distilled water until the filtrate was neutral, the product was dried in a drying oven at 80°C, and the dried white solid was ground into powder to obtain the modified Hydrotalcite;

[0060] 6) Melt mixing: the flame-reta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com