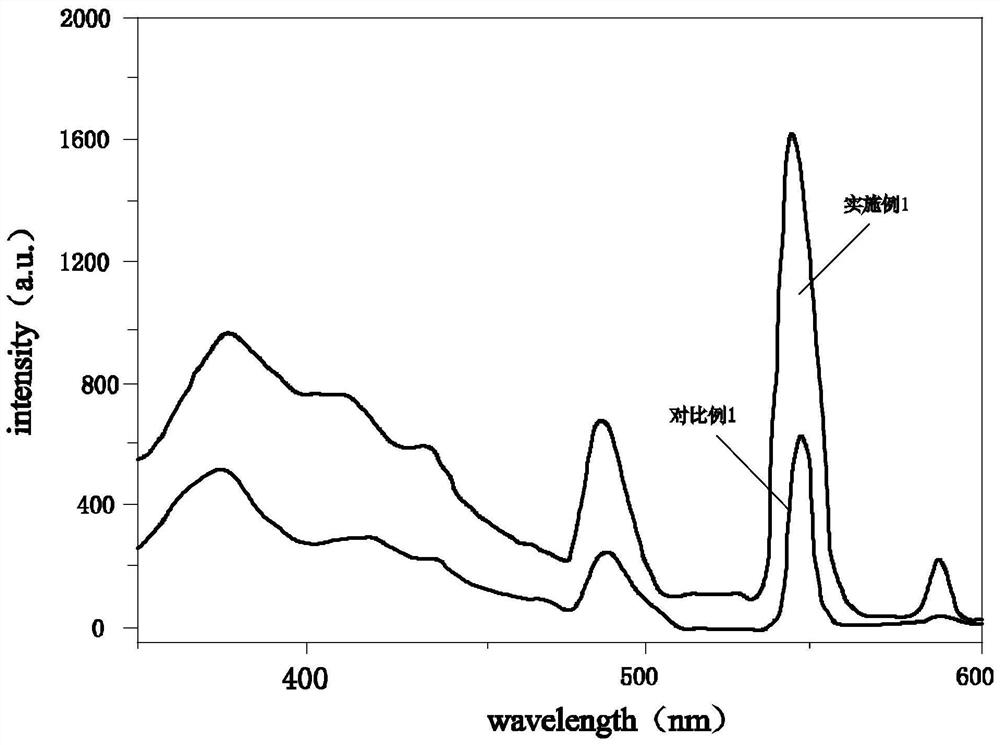

High-density terbium/cerium doped scintillation glass and preparation method thereof

A scintillation glass, cerium doping technology, applied in glass manufacturing equipment, glass molding, manufacturing tools and other directions, can solve problems such as unsatisfactory luminescence effect, concentration quenching, etc., to improve scintillation performance, improve blocking ability, improve glass The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

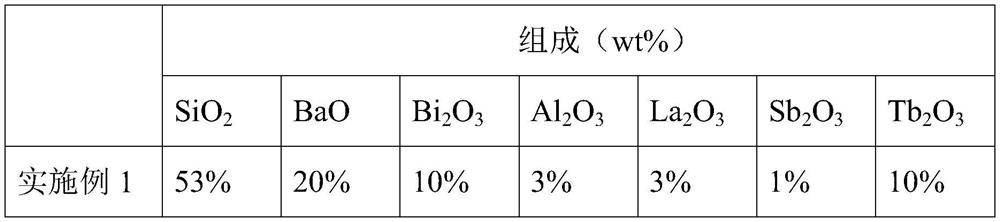

Embodiment 1

[0037] The scintillation glass of this embodiment can be prepared in the following manner:

[0038] Referring to the glass composition in Table 1 below, use an electronic balance (accurate to 0.01g) to accurately weigh SiO 2 Raw material, BaO raw material, Bi 2 o 3 Raw materials, Al 2 o 3 Raw materials, La 2 o 3 Raw materials, Sb 2 o 3 Raw materials and Tb 2 o 3 Raw materials, a total of 20g of ingredients, and then use an agate mortar to fully grind and mix them evenly;

[0039] Among them, the Bi 2 o 3 The raw material is doped with Ce 3+ Ionic Bi 2 o 3 Raw materials, which are prepared by the following method: dissolving bismuth nitrate in ethylene glycol to obtain a solution with a concentration of 0.1mol / L, then adding cerium nitrate Ce (NO 3 ) 3 , so that cerium nitrate Ce(NO 3 ) 3 and bismuth nitrate Bi(NO 3 ) 3 The mass ratio is 0.08:1, add concentrated ammonia water to adjust the pH value to 9, stir evenly, transfer to a polytetrafluoroethylene rea...

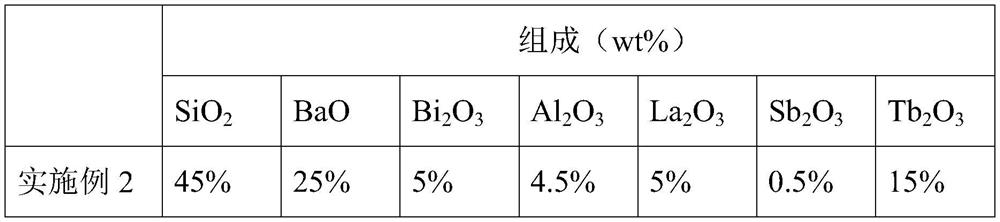

Embodiment 2

[0045] The scintillation glass of this embodiment can be prepared in the following manner:

[0046] Referring to the glass composition in Table 2 below, use an electronic balance (accurate to 0.01g) to accurately weigh SiO 2 Raw material, BaO raw material, Bi 2 o 3 Raw materials, Al 2 o 3 Raw materials, La 2 o 3 Raw materials, Sb 2 o 3 Raw materials and Tb 2 o 3 Raw materials, a total of 20g of ingredients, and then use an agate mortar to fully grind and mix them evenly;

[0047] Among them, the Bi 2 o 3 The raw material is doped with Ce 3+ Ionic Bi 2 o 3 Raw materials, which are prepared by the following method: dissolving bismuth nitrate in ethylene glycol to obtain a solution with a concentration of 0.1mol / L, then adding cerium nitrate Ce (NO 3 ) 3 , so that cerium nitrate Ce(NO 3 ) 3 and bismuth nitrate Bi(NO 3 ) 3 The mass ratio is 0.01:1, add concentrated ammonia water to adjust the pH value to 9, stir evenly, transfer to a polytetrafluoroethylene rea...

Embodiment 3

[0053] The scintillation glass of this embodiment can be prepared in the following manner:

[0054] Referring to the glass composition in Table 3 below, use an electronic balance (accurate to 0.01g) to accurately weigh SiO 2 Raw material, BaO raw material, Bi 2 o 3 Raw materials, Al 2 o 3 Raw materials, La 2 o 3 Raw materials, Sb 2 o 3 Raw materials and Tb 2 o 3 Raw materials, a total of 20g of ingredients, and then use an agate mortar to fully grind and mix them evenly;

[0055] Among them, the Bi 2 o 3 The raw material is doped with Ce 3+ Ionic Bi 2 o 3 Raw materials, which are prepared by the following method: dissolving bismuth nitrate in ethylene glycol to obtain a solution with a concentration of 0.1mol / L, then adding cerium nitrate Ce (NO 3 ) 3 , so that cerium nitrate Ce(NO 3 ) 3 and bismuth nitrate Bi(NO 3 ) 3 The mass ratio is 0.15:1, add concentrated ammonia water to adjust the pH value to 9, stir evenly, transfer to a polytetrafluoroethylene rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com