Graphene oxide reinforced silicon boron carbon nitrogen ceramic composite material and preparation method thereof

A ceramic composite material, silicon-boron-carbon-nitrogen technology, applied in the field of ceramic absorbing materials, can solve the problems of material and air impedance mismatch, weaken electromagnetic wave attenuation, affect the actual performance of composite materials, etc., to increase the dissipation path, enhance Interface polarization effect, good effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

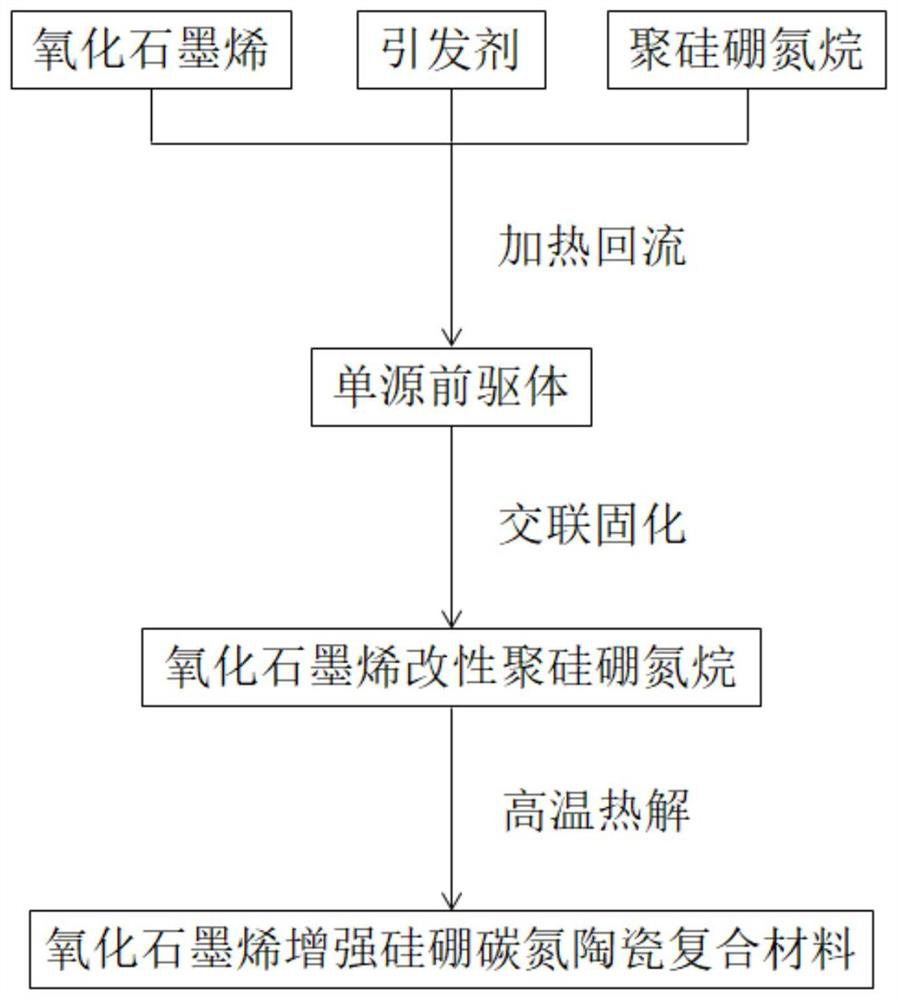

[0039] Another embodiment of the present invention provides a method for preparing the graphene oxide-reinforced silicon-boron-carbon-nitride ceramic composite material as described above, comprising the following steps:

[0040] S1. Preparation of graphene oxide dispersion: adding graphene oxide into anhydrous dimethylformamide, and ultrasonically dispersing to obtain graphene oxide dispersion;

[0041] S2. Graphene oxide modified polysilaborazane: under an inert atmosphere, add polysilaborazane solution to the graphene oxide dispersion, then add an initiator, ultrasonically disperse, then heat to reflux, and then heat up to 150-250 ° C and heat preservation, curing and cross-linking, to obtain graphene oxide modified polysilaborazane;

[0042] S3. High-temperature pyrolysis: raise the temperature of the graphene oxide-modified polysilaborazane to 1300-1600°C in an inert atmosphere and keep it warm for pyrolysis reaction, and then naturally cool down to room temperature to ob...

Embodiment 1

[0058] A preparation method of graphene oxide reinforced silicon-boron-carbon-nitrogen ceramic composite material, comprising the following steps:

[0059] S1. Preparation of graphene oxide dispersion: ultrasonically clean the round-bottomed flask twice with deionized water and anhydrous dimethylformamide, then add 0.06g of graphene oxide and 10mL of anhydrous dimethylformamide into the round-bottomed flask , put the round-bottomed flask into an ultrasonic machine after being sealed, and ultrasonicate with a power of 220w for 6 hours to obtain a graphene oxide dispersion;

[0060] S2. Graphene oxide modified polysilaborazane: under an inert atmosphere, add 1 g of polysilaborazane solution to the graphene oxide dispersion, then add 0.02 g of dicumyl peroxide, and ultrasonicate with a power of 220w 30min, then heated to reflux at 80°C for 72h, then heated to 190°C at a rate of 5°C / min and kept for 24h to cure and crosslink to obtain a black solid, which is graphene oxide-modifie...

Embodiment 2

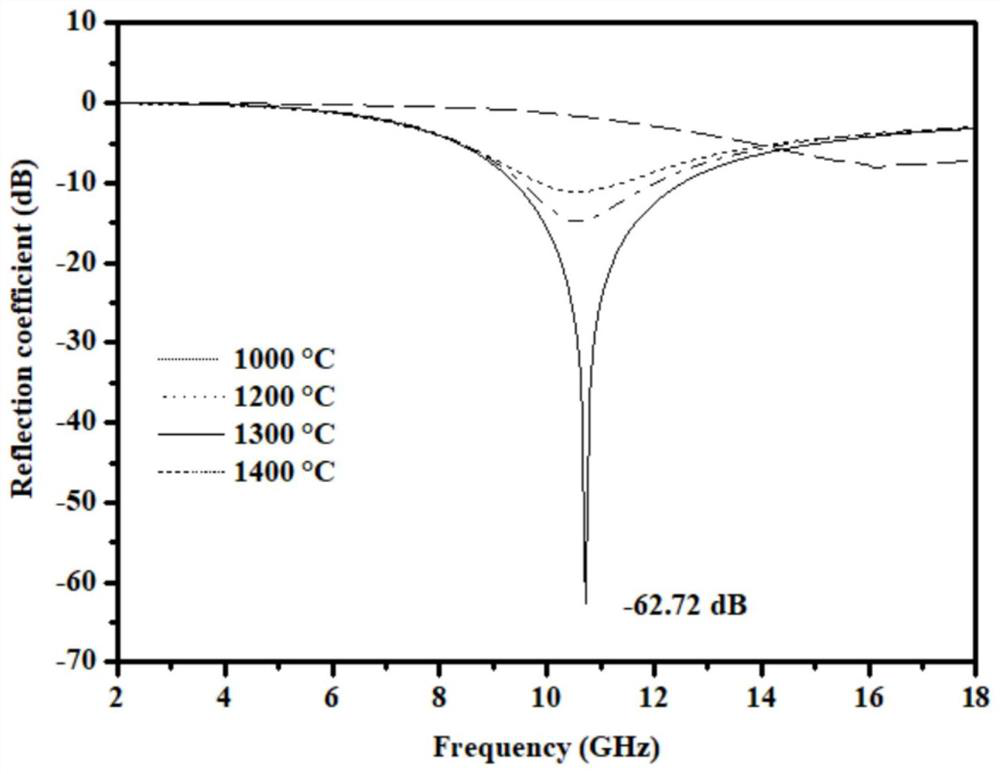

[0066] Example 2 is basically the same as Example 1, the difference being that in step S1, 0, 0.04g, 0.06g, and 0.08g of graphene oxide were respectively added to 10mL of anhydrous dimethylformamide, and the preparation concentration was 0g / L , 4g / L, 6g / L, 8g / L graphene oxide dispersion ( Figure 4 respectively corresponding to 4%wt GO, 6%wt GO and 8%wt GO) to carry out subsequent steps S2-S3, and in step S3, the graphene oxide modified polysilicon boron in step S2 is The temperature of azane was raised to 1300°C at a rate of 5°C / min and kept for 2h.

[0067] The electromagnetic wave absorption properties of composites prepared with different concentrations of graphene oxide dispersions are as follows: Figure 4 shown. Depend on Figure 4 It can be seen that the electromagnetic wave absorption performance of the composite material prepared by using the graphene oxide dispersion with a mass concentration of 6%wt is the best, and the mass ratio of graphene oxide to polysilabo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com