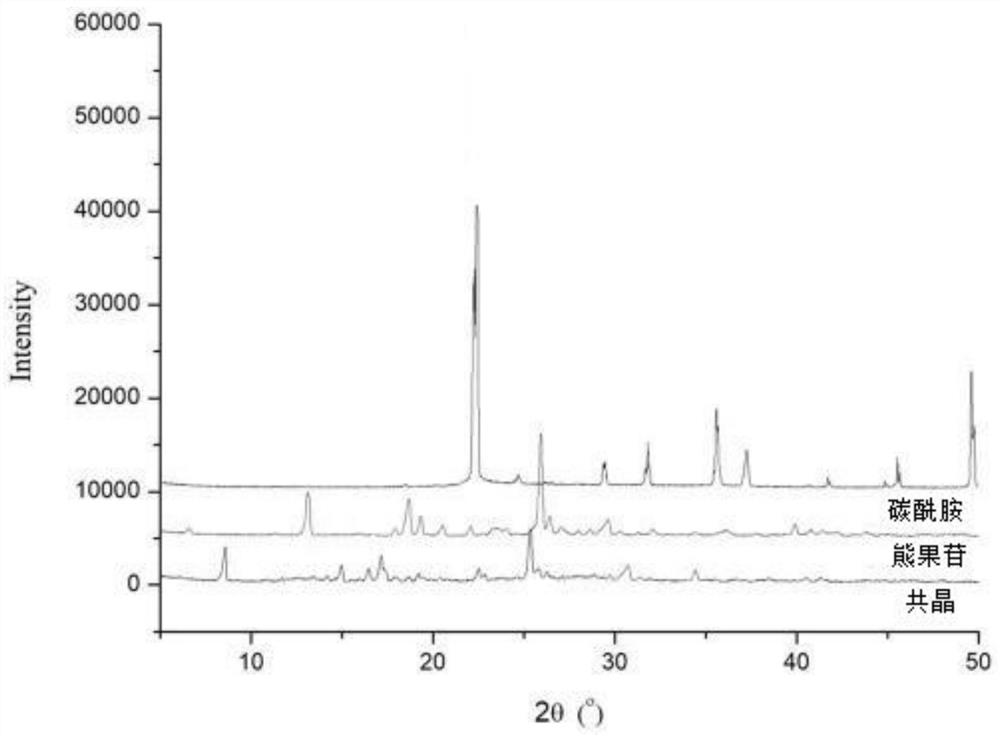

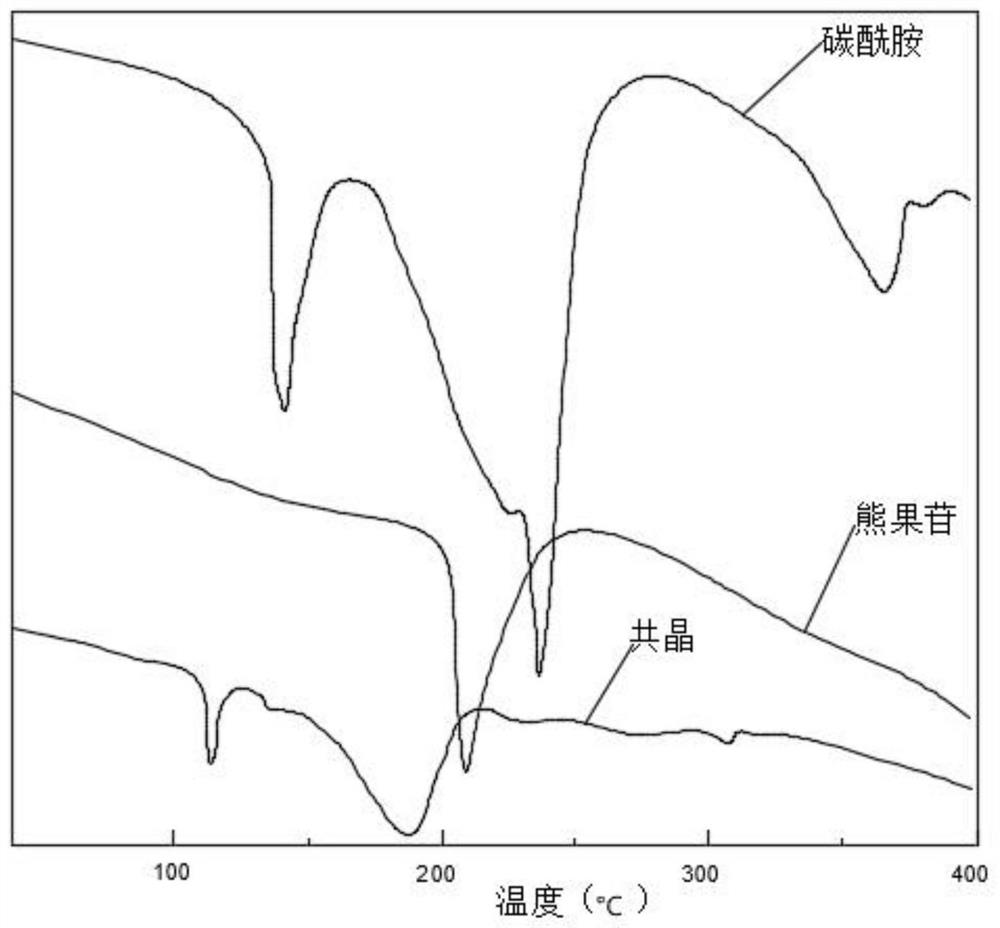

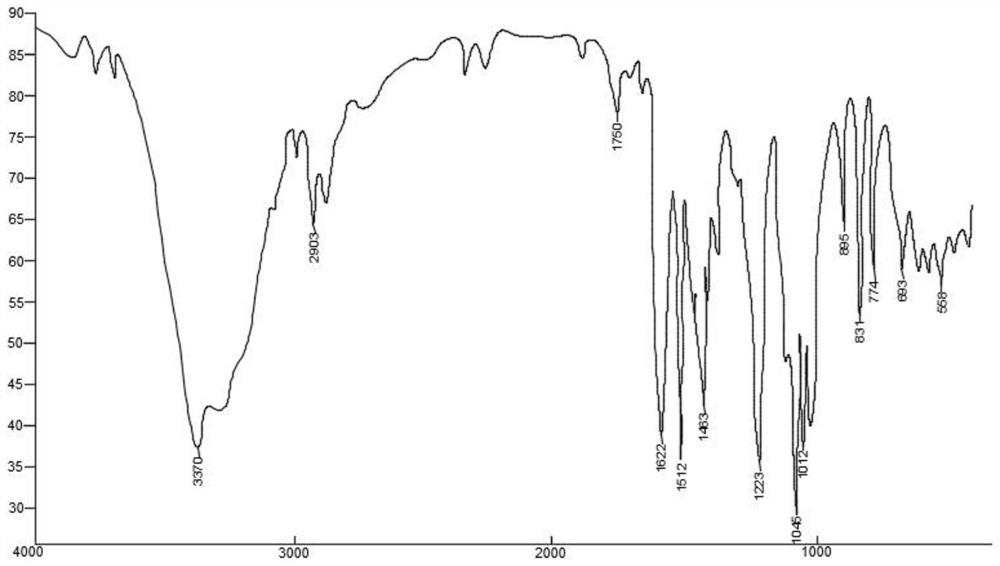

Arbutin-carbamide eutectic crystal as well as preparation method, preparation and application thereof

A technology of arbutin and carbonamide, which is applied in the field of arbutin-carbonamide co-crystal and its preparation, and achieves the effects of good crystallization effect, improved bioavailability and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of arbutin-carbamide co-crystal, comprising the steps of:

[0029] The mixed powder that arbutin and carbonamide are formed with a mol ratio of 1:1 is placed in a mixed solvent composed of water and ethanol, wherein, V (mixed solvent): m (mixed powder) is 15mL:1g, The volume ratio of the water and the ethanol in the mixed solvent is 1:1;

[0030] Then ultrasonically mix for 20min under the conditions of 20°C, ultrasonic power 250W, and ultrasonic frequency 40KHz, then continue to stir at a constant speed for 20min at a speed of 25rmp, and finally reduce the speed to 10rmp, lower the temperature to 5°C, and continue to stir at a constant speed for 10min. Finally, let stand for 24 hours, remove the solvent by rotary evaporation under reduced pressure, and dry for 1 hour under the conditions of vacuum pressure 45Pa and temperature 55°C to obtain arbutin-carbamide eutectic.

Embodiment 2

[0032] A preparation method of arbutin-carbamide co-crystal, comprising the steps of:

[0033] The mixed powder that arbutin and carbonamide are formed with a mol ratio of 1:1 is placed in a mixed solvent composed of water and ethanol, wherein, V (mixed solvent): m (mixed powder) is 15mL:1g, The volume ratio of the water and the ethanol in the mixed solvent is 1:1;

[0034] Then ultrasonically mix for 30min under the conditions of 25°C, ultrasonic power 250W, and ultrasonic frequency 40KHz, then continue to stir at a constant speed for 30min at a speed of 30rmp, and finally reduce the speed to 12rmp, lower the temperature to 8°C, and continue to stir at a constant speed for 15min. Finally, let stand for 24 hours, remove the solvent by rotary evaporation under reduced pressure, and dry for 1 hour under the conditions of vacuum pressure 45Pa and temperature 55°C to obtain arbutin-carbamide eutectic.

Embodiment 3

[0036] A preparation method of arbutin-carbamide co-crystal, comprising the steps of:

[0037] The mixed powder that arbutin and carbonamide are formed with a mol ratio of 1:1 is placed in a mixed solvent composed of water and ethanol, wherein, V (mixed solvent): m (mixed powder) is 15mL:1g, The volume ratio of the water and the ethanol in the mixed solvent is 1:1;

[0038]Then ultrasonically mix for 25min under the conditions of 30°C, ultrasonic power 250W, and ultrasonic frequency 40KHz, then continue to stir at a constant speed for 25min at a speed of 28rmp, and finally reduce the speed to 11rmp, lower the temperature to 10°C, and continue to stir at a constant speed for 12min. Finally, let stand for 24 hours, remove the solvent by rotary evaporation under reduced pressure, and dry for 1 hour under the conditions of vacuum pressure 45Pa and temperature 55°C to obtain arbutin-carbamide eutectic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com