Preparation method of hyper-branched water-based dispersant

A water-based dispersant and branching technology, applied in the field of preparation of hyperbranched water-based dispersants, can solve the problems of short wall adhesion time, inability to firmly bond the wall, and reduced viscosity of the coating carrier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

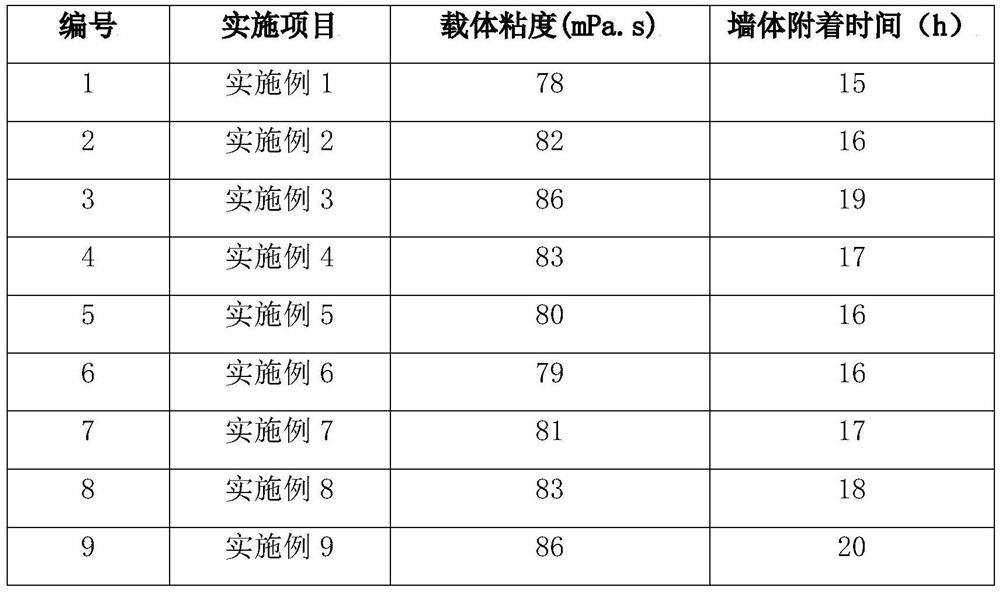

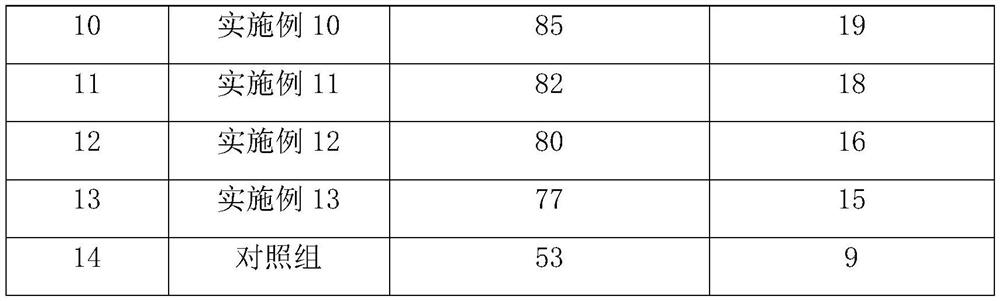

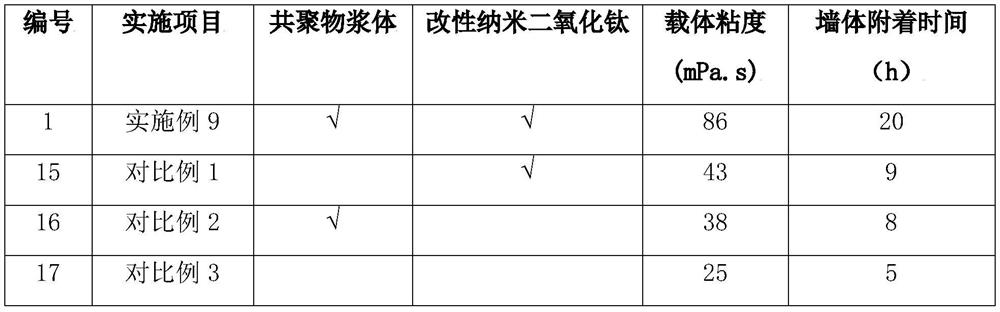

Examples

preparation example Construction

[0027] Specifically, an embodiment of the present invention provides a method for preparing a hyperbranched aqueous dispersant, comprising the following steps:

[0028] 1) adding the ultrafine inorganic powder into the styrene-maleic anhydride copolymer solution and mixing evenly to obtain a copolymer slurry;

[0029] 2) Put the modified nano-titanium dioxide into a container, add sodium hydroxide solution to it, stir for 10 to 15 minutes, filter, then add acrylic acid to it, and stand and soak for 1 to 2 hours at a temperature of 45 to 50°C to obtain Modified nano titanium dioxide solution;

[0030] 3) After mixing the copolymer slurry and the modified nano-titanium dioxide solution, pour it into a stirring tank, feed nitrogen protection, and stir for 20-25 minutes to obtain a mixed slurry;

[0031] 4) Pass the mixed slurry through the atomizer to form atomized droplets and enter the drying chamber for drying and dehydration;

[0032] 5) Cool the dried mixed slurry to room ...

Embodiment 1

[0044] Add the ultrafine inorganic powder into the styrene-maleic anhydride copolymer solution and mix evenly to obtain a copolymer slurry with a solid content of 30%, which is ready for use; mix anatase titanium dioxide and rutile titanium dioxide with a mass ratio of 3:1 Titanium dioxide is mixed into a nano-titanium dioxide mixture, and then the nano-titanium dioxide mixture, titanate coupling agent, absolute ethanol and deionized water are mixed in a mass ratio of 5:2:3:4, and the resulting mixture is ultrasonically treated. Re-drying treatment, after drying, wash with absolute ethanol and air-dry naturally to obtain modified nano-titanium dioxide; put the modified nano-titanium dioxide into a container, add a sodium hydroxide solution with a mass fraction of 40% to it, and filter after stirring for 15 minutes , and then add acrylic acid to it, and stand and soak for 1.5h at a temperature of 50°C to obtain a modified nano-titanium dioxide solution; mix the copolymer slurry ...

Embodiment 2

[0046]Add the ultrafine inorganic powder into the styrene-maleic anhydride copolymer solution and mix evenly to obtain a copolymer slurry with a solid content of 30%, which is ready for use; mix anatase titanium dioxide and rutile titanium dioxide with a mass ratio of 3:2 Titanium dioxide is mixed into a nano-titanium dioxide mixture, and then the nano-titanium dioxide mixture, titanate coupling agent, absolute ethanol and deionized water are mixed in a mass ratio of 5:2:3:4, and the resulting mixture is ultrasonically treated. Re-drying treatment, after drying, wash with absolute ethanol and air-dry naturally to obtain modified nano-titanium dioxide; put the modified nano-titanium dioxide into a container, add a sodium hydroxide solution with a mass fraction of 40% to it, and filter after stirring for 15 minutes , and then add acrylic acid to it, and stand and soak for 1.5h at a temperature of 50°C to obtain a modified nano-titanium dioxide solution; mix the copolymer slurry w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com