Microbial agent for treating sludge of sewage plant and preparation method thereof

A microbial agent and sewage plant technology, which is applied in the field of microbial agent for sewage treatment plant sludge and its preparation, can solve problems such as pollution and high cost, and achieve the effect of easy preparation and remarkable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

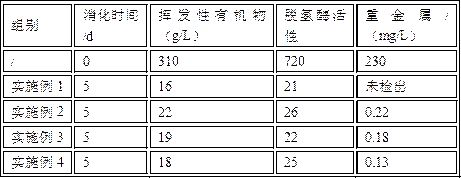

Examples

Embodiment 1

[0039] A kind of microbial inoculum agent for treating sewage plant sludge, in parts by weight, comprises the following components:

[0040] 55 parts of thermophilic Clostridium, 27 parts of Pseudomonas denitrification, 27 parts of Rhodospirillum rubrum, 18 parts of denitrifying bacteria, and 18 parts of yeast. The denitrification Pseudomonas selects ATCC13867,

[0041] Clostridium daqing-WL is selected as the thermophilic clostridia.

[0042] A method for preparing a microbial agent for treating sewage sludge, comprising the following steps:

[0043] Step 1. Strain activation

[0044] Select non-pathogenic Clostridium spp., Pseudomonas denitrificans, Rhodospirillum rubrum, denitrifying bacteria

[0045] , Yeast, respectively inoculated into their respective test tube slant culture medium, cultivated in the incubator for 4 days, the temperature of the incubator is 28-30°C, and stored in a 4-5°C freezer after the cultivation is completed for later use;

[0046] Step 2, Erle...

Embodiment 2

[0055] A kind of microbial inoculum agent for treating sewage plant sludge, in parts by weight, comprises the following components:

[0056] 50 parts of thermophilic Clostridium, 25 parts of Pseudomonas denitrification, 25 parts of Rhodospirillum rubrum, 15 parts of denitrifying bacteria, and 15 parts of yeast. The denitrification Pseudomonas selects ATCC13867,

[0057] Clostridium daqing-WL is selected as the thermophilic clostridia.

[0058] A method for preparing a microbial agent for treating sewage sludge, comprising the following steps:

[0059] Step 1. Strain activation

[0060] Select non-pathogenic Clostridium spp., Pseudomonas denitrificans, Rhodospirillum rubrum, denitrifying bacteria

[0061] , Yeast, respectively inoculated into their respective test tube slant medium, cultivated in the incubator for 2 days, the temperature of the incubator is 30~32°C, and stored in a 5~6°C freezer after the cultivation is over;

[0062] Step 2, Erlenmeyer flask culture medium p...

Embodiment 3

[0071] A kind of microbial inoculum agent for treating sewage plant sludge, in parts by weight, comprises the following components:

[0072] 60 parts of Clostridium thermophilic, 30 parts of Pseudomonas denitrification, 30 parts of Rhodospirillum rubrum, 20 parts of denitrifying bacteria, and 20 parts of yeast. The Pseudomonas denitrifica is selected from ATCC13867, and the Clostridium thermophilic is selected from Clostridium daqing-WL.

[0073] A method for preparing a microbial agent for treating sewage sludge, comprising the following steps:

[0074] Step 1. Strain activation

[0075] Select non-pathogenic Clostridium spp., Pseudomonas denitrificans, Rhodospirillum rubrum, denitrifying bacteria

[0076] , Yeast, respectively inoculated into their respective test tube slant medium, cultivated in the incubator for 5 days, the temperature of the incubator is 35~37°C, after the cultivation is completed, they are stored in a refrigerator at 7~8°C for later use;

[0077] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com