Oxygen reduction catalyst and preparation method thereof

A catalyst, sodium hydroxide technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of complex preparation method, and achieve the effect of simple preparation method, convenient operation, and catalytic activity of aerobic reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

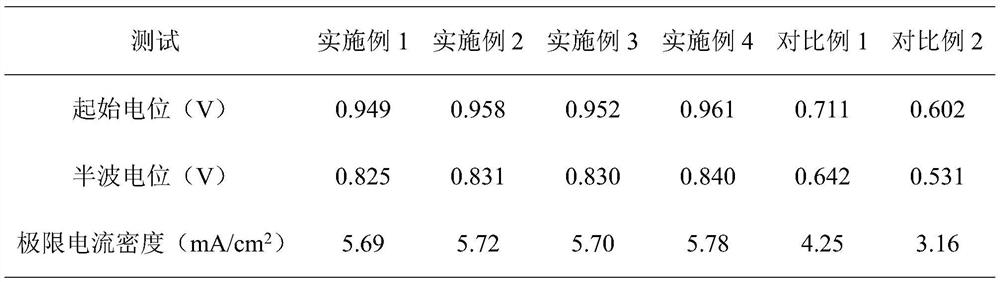

Examples

Embodiment 1

[0026] A preparation method of an oxygen reduction catalyst, characterized in that the preparation method comprises the following steps:

[0027] (1) Preparation of dithiocarboxylated polyethyleneimine: Add distilled water solvent, polyethyleneimine and sodium hydroxide into the reaction flask, stir well, place in a constant temperature water bath, stir at a constant speed at 30°C and slowly drop Add carbon disulfide and react for 2 hours. After the reaction is completed, add ethanol solvent until a flocculent product is precipitated, filter to remove the solvent, wash with distilled water and dry to obtain dithiocarboxylated polyethyleneimine;

[0028] Wherein, the molecular weight of polyethyleneimine is 1800; The mass ratio of polyethyleneimine, sodium hydroxide and carbon disulfide is 100:50:120;

[0029] (2) Preparation of dithiocarboxylated polyethyleneimine-cobalt chelate: adding pH to the reaction flask is 5 hydrochloric acid solution, then the molar concentration is 0...

Embodiment 2

[0036] A preparation method of an oxygen reduction catalyst, characterized in that the preparation method comprises the following steps:

[0037] (1) Preparation of dithiocarboxylated polyethyleneimine: Add distilled water solvent, polyethyleneimine and sodium hydroxide into the reaction flask, stir evenly, place in a constant temperature water bath, stir at a constant speed at 50°C and slowly drop Add carbon disulfide and react for 4 hours. After the reaction is completed, add ethanol solvent until a flocculent product is precipitated, filter to remove the solvent, wash with distilled water and dry to obtain dithiocarboxylated polyethyleneimine;

[0038] Wherein, the molecular weight of polyethyleneimine is 3000; The mass ratio of polyethyleneimine, sodium hydroxide and carbon disulfide is 100:80:200;

[0039] (2) the preparation of dithiocarboxylated polyethyleneimine-cobalt chelate: add the hydrochloric acid solution that pH is 6 in reaction flask, then the cobalt chloride ...

Embodiment 3

[0045] A preparation method of an oxygen reduction catalyst, characterized in that the preparation method comprises the following steps:

[0046] (1) Preparation of dithiocarboxylated polyethyleneimine: Add distilled water solvent, polyethyleneimine and sodium hydroxide into the reaction flask, stir evenly, place in a constant temperature water bath, stir at a constant speed at 40°C and slowly drop Add carbon disulfide and react for 3 hours. After the reaction is completed, add ethanol solvent until a flocculated product is precipitated, filter to remove the solvent, wash with distilled water and dry to obtain dithiocarboxylated polyethyleneimine;

[0047] Wherein, the molecular weight of polyethyleneimine is 3500; The mass ratio of polyethyleneimine, sodium hydroxide and carbon disulfide is 100:110:280;

[0048] (2) the preparation of dithiocarboxylated polyethyleneimine-cobalt chelate: add the hydrochloric acid solution that pH is 5 in reaction flask, then the cobalt chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com