Preparation method of micron-sized spherical particle section for electron microscope observation

A spherical particle, micron-scale technology, applied in the preparation of test samples, material analysis using wave/particle radiation, instruments, etc., can solve the problems of cumbersome processing steps, long polishing time, large consumption of raw materials, etc., and achieve polishing time Short, low cost, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] To prepare a section of a micron-sized spherical particle for SEM observation, follow the steps below:

[0035] (1) Paste the double-sided conductive carbon tape on the aluminum metal substrate with a size of 8mm×8mm;

[0036] (2) Take a small amount of LiNiCoMnO with a toothpick 2 The battery positive electrode material powder is spread flat on the conductive tape, and the excess powder is blown away with a blower, and only the powder stuck on the conductive tape remains;

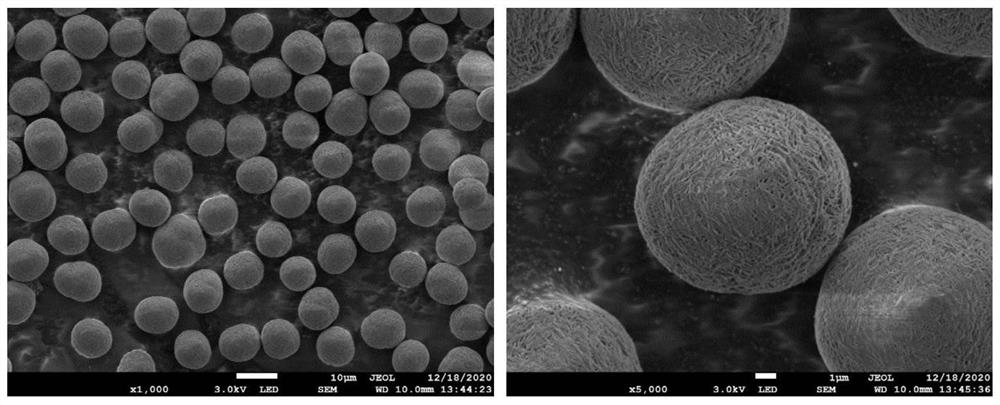

[0037] (3) Put the aluminum metal substrate with powder in the argon ion polishing machine for polishing, adopt the plane polishing mode, the ion gun angle is 2°, and the polishing voltage and time are 7kV 5min+4kV 10min+1kV 10min, and the satisfaction can be obtained. The cross-section observed by the scanning electron microscope, the scanning electron microscope picture of the spherical particle cross-section after ion polishing is as follows figure 2 shown.

Embodiment 2

[0039] To prepare a section of a micron-sized spherical particle for SEM observation, follow the steps below:

[0040] (1) Paste the double-sided conductive copper tape on the copper metal substrate with a size of 8mm×8mm;

[0041] (2) Take a small amount of LiNiCoMnO with a toothpick 2 The battery positive electrode material powder is spread flat on the conductive tape, and the excess powder is blown away with a hair dryer;

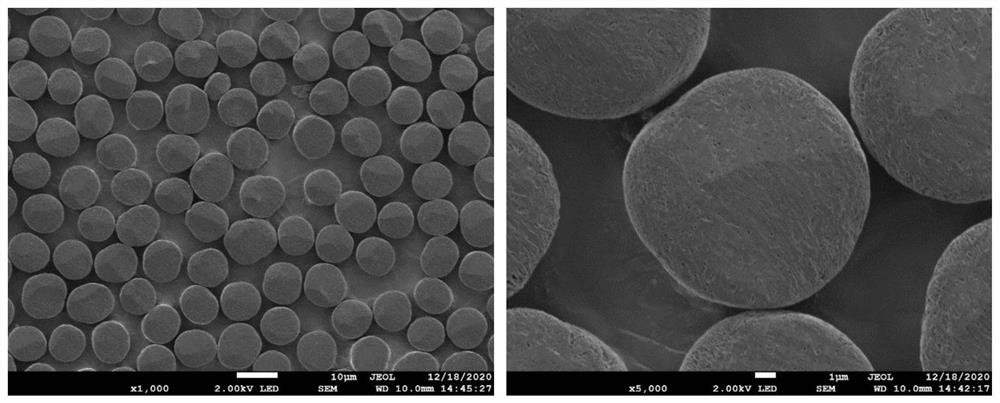

[0042] (3) Put the copper metal substrate with powder in the argon ion polishing machine for polishing, adopt the plane polishing mode, the ion gun angle is 0.5°, and the polishing voltage and time are 7kV 5min+4kV 10min+1kV 10min, and the satisfaction can be obtained. The cross-section observed by the scanning electron microscope, the scanning electron microscope picture of the spherical particle cross-section after ion polishing is as follows image 3 shown.

Embodiment 3

[0044] To prepare a section of a micron-sized spherical particle for SEM observation, follow the steps below:

[0045] (1) Paste the double-sided conductive copper tape on the aluminum metal substrate with a size of 8mm×8mm;

[0046] (2) Take a small amount of LiNiCoMnO with a toothpick 2 The battery positive electrode material powder is spread flat on the conductive tape, and the excess powder is blown away with a hair dryer;

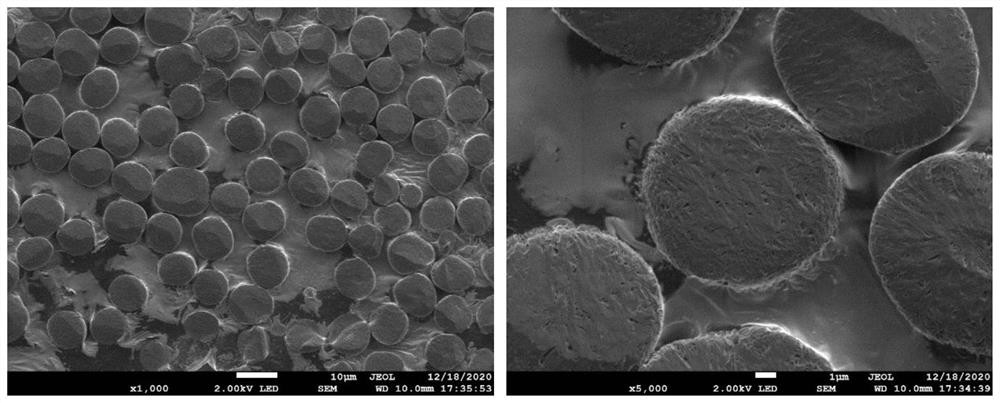

[0047] (3) Put the copper metal substrate with powder in the argon ion polishing machine for polishing, adopt the plane polishing mode, the ion gun angle is 0°, and the polishing voltage and time are 7kV 5min+4kV 10min+1kV 10min, and the satisfactory The cross-section observed by the scanning electron microscope, the scanning electron microscope picture of the spherical particle cross-section after ion polishing is as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com